In this article, we’ll take a closer look at the potential applications of rigid-flex circuit boards in power distribution systems, exploring their benefits, challenges, and considerations.

In today’s fast-paced technological advancements, there is an ever-increasing need for compact, efficient power distribution systems. To meet these requirements, engineers are exploring innovative solutions, with rigid-flex circuit boards becoming a promising option.

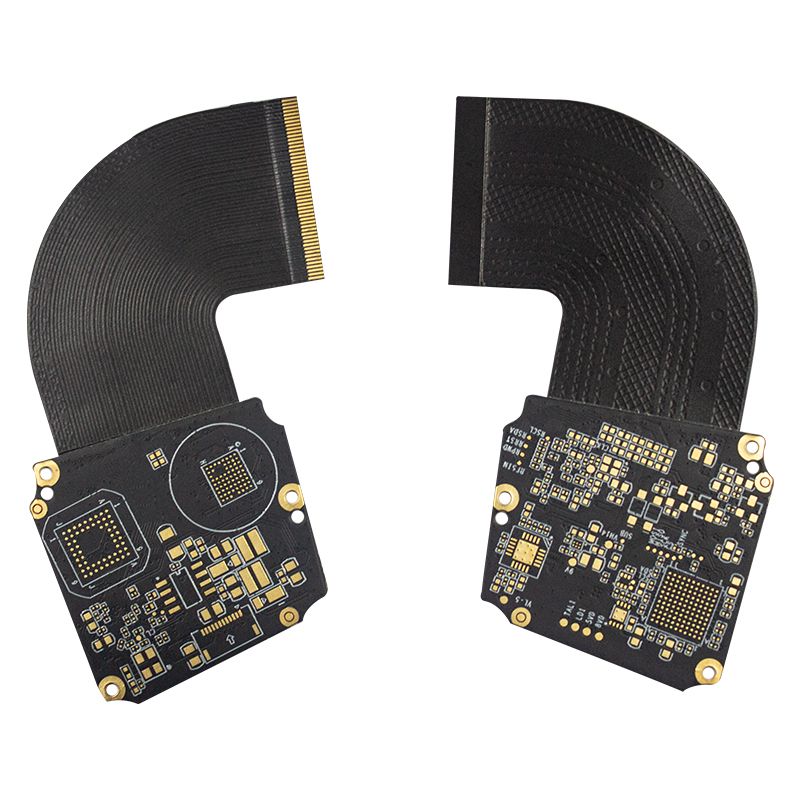

1.Learn about rigid-flex circuit board:

Rigid-flex circuit boards are a combination of flexible and rigid substrates that increase design flexibility while providing stability and durability. These boards consist of multiple layers of flexible polyimide film and rigid FR-4 or other suitable rigid substrates interconnected by plated through holes (PTH). This structure allows the board to bend and bend while maintaining the necessary rigidity.

2.Advantages of Rigid Flexible Circuit Boards in Power Distribution Systems:

Space efficiency One of the main reasons to consider rigid-flex circuit boards in power distribution systems is their space-saving capabilities. Their ability to conform to three-dimensional shapes allows important components to be placed in tight spaces, optimizing the overall system footprint.

Reliability and durability Power distribution systems often encounter harsh environmental conditions, including temperature changes, vibration, and electromagnetic interference. Rigid-flex circuit boards are designed to address these challenges, providing excellent mechanical strength, resistance to shock and vibration, and enhanced reliability in harsh environments.

Improve signal integrity Signal integrity is critical in power distribution systems. Rigid-flex circuit boards minimize signal loss and impedance mismatches by providing controlled impedance routing. Maintaining signal integrity helps ensure accurate transmission of power and data throughout the system.

Enhance thermal management An efficient power distribution system requires effective heat dissipation. Rigid-flex circuit boards can contain thermal vias and heat sinks to improve heat conduction and dissipation. By managing heat effectively, the overall performance of your system can be optimized.

Design flexibility Rigid-flex circuit boards give engineers the freedom to design complex and compact layouts, allowing for creativity in system architecture. The ability to create complex interconnects and integrate multiple components onto a single board increases design flexibility and enables more efficient power distribution systems.

3.Challenges of implementing rigid-flex circuit boards in power distribution systems:

Cost considerations Implementation of rigid-flex circuit boards may involve higher initial costs compared to traditional PCBs. Factors such as material selection, manufacturing complexity and testing requirements can all add to these additional costs. However, the long-term benefits, improved performance, and reduced system complexity often outweigh the initial investment.

Manufacturing complexity The manufacturing process of rigid-flex circuit boards is different from traditional PCBs and requires specialized technology and expertise. The complexity involved in manufacturing flexible and rigid substrates simultaneously increases manufacturing complexity, creating potential challenges in producing reliable and high-quality circuit boards.

Design limitations The design of rigid-flex circuit boards requires careful consideration of bend radii, material compatibility, and stress points. Inadequate design and planning can cause unnecessary stress, shortening the life and performance of the board. Working with an experienced PCB manufacturer during the design phase is critical to effectively overcome these limitations.

Testing and Troubleshooting When troubleshooting or testing rigid-flex circuit boards, identifying and isolating problems can be more challenging than with traditional PCBs. The complex nature of these boards, with flexible and rigid sections, requires careful inspection to pinpoint potential failure points.

4.Considerations for Implementing Rigid-Flex Circuit Boards:

Design optimization To ensure successful integration of rigid-flex circuit boards into power distribution systems, a comprehensive design optimization process is critical. Working with experienced PCB designers and manufacturers can help solve design challenges and optimize layout for cost-effectiveness, reliability and manufacturability.

Material selection Choosing the right materials is critical to the performance and durability of rigid-flex circuit boards. Compatibility between flexible and rigid materials is critical to maintaining mechanical integrity. In addition, material selection should consider factors such as thermal stability, signal transmission capabilities, and resistance to environmental conditions.

Environmental factors Power distribution systems may experience extreme operating environments ranging from high temperatures to moisture. It is important to ensure that the rigid-flex board selected can withstand these conditions without compromising performance. Choosing materials with appropriate temperature ratings, moisture resistance, and protective coatings can increase system reliability and longevity

5.Case Study:Rigid-Flex Circuit Boards in Power Distribution Systems

Aerospace and Defense Rigid-flex circuit boards are widely used in aerospace and defense fields, where compact, lightweight power distribution systems are critical. These panels provide the flexibility needed to fit into tight spaces while being able to withstand the harsh environmental conditions associated with aircraft and military applications. Medical devices Power distribution systems in medical equipment rely on the integrity and reliability of circuit boards for accurate operation. Rigid-flex circuit boards enable compact designs for medical devices such as implants, monitoring equipment, and surgical tools. The boards can be bent to fit smaller form factors while maintaining a high level of electrical performance.

Consumer electronics Consumer electronics such as smartphones and wearable devices require space-saving power distribution solutions. Rigid-flex circuit boards enable designers to optimize space utilization and integrate complex functionality into limited layouts. The flexibility and durability of these boards make them ideal for power distribution systems in consumer electronics.

Industrial automation Power distribution systems in industrial automation environments often involve complex wiring and limited space. Rigid-flex circuit boards offer reliable and compact solutions for these applications, offering enhanced levels of control, improved signal transmission and space optimization.

Conclusion:

Rigid-flex circuit boards have huge potential in power distribution systems, offering advantages such as space efficiency, reliability, improved signal integrity, enhanced thermal management and design flexibility. However, given the associated manufacturing complexities, cost implications and design constraints, proper planning and collaboration with an experienced PCB manufacturer is critical to successful implementation. By optimizing the design, choosing the right materials, and considering environmental factors, rigid-flex circuit boards can undoubtedly revolutionize power distribution systems in various industries. As technology continues to advance, it is expected that the integration of rigid-flex circuit boards will become more common in power distribution systems, helping to meet the growing demand for compactness, efficiency and reliability.

Post time: Sep-15-2023

Back