Introduce:

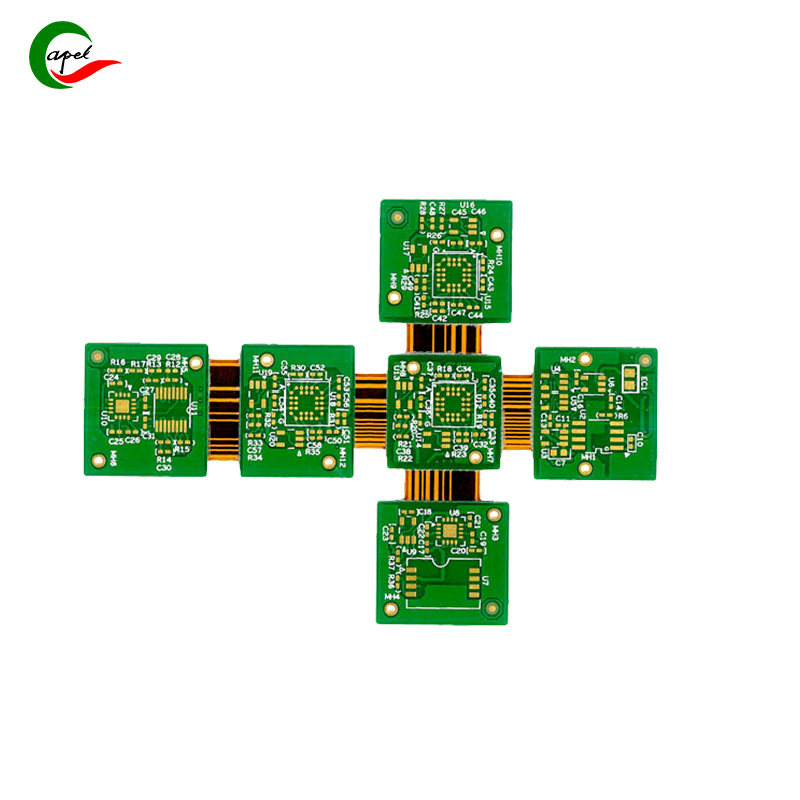

In the evolving world of wireless technology, the need for efficient and effective wireless sensor networks continues to grow. As a technology enthusiast or professional in this field, you may be wondering whether it is possible to prototype a printed circuit board (PCB) customized specifically for wireless sensor networks. In this blog, we explore the answer to this question while highlighting the expertise of Capel, a company with 15 years of experience in circuit board manufacturing.

1. The importance of prototyping in the development of wireless sensor networks:

Prototyping plays a vital role in the development of any technological advancement, and wireless sensor networks are no exception. Minor design flaws or integration issues in the initial stages can lead to major setbacks or even failure of the entire project. This is why being able to prototype PCBs for wireless sensor networks is crucial to avoid such problems.

2. Can you prototype a PCB for a wireless sensor network?

Yes, you can definitely prototype a PCB for a wireless sensor network. With Capel’s extensive experience in circuit board manufacturing and their commitment to staying at the forefront of technological advancements, they can provide the necessary expertise and tools for your prototyping needs. Additionally, their knowledge and dedication make them an ideal partner for wireless sensor network development challenges.

3. Leverage Capel’s 15 years of experience:

Capel brings an impressive 15 years of experience, giving them a competitive edge in the circuit board manufacturing space. Their expertise combined with constant innovation makes Capel the perfect choice for PCB prototyping of wireless sensor networks. Whether it’s exceeding expectations, meeting tight deadlines, or resolving unforeseen issues with cost-effective solutions, Capel’s experience excels in every aspect.

4. Benefits of choosing Capel to meet your PCB prototyping needs:

A. Technologically Advanced Facilities: Capel has a state-of-the-art manufacturing facility equipped with the latest machinery, enabling it to provide quality PCB prototypes for wireless sensor networks.

b. Team of Experts: Capel prides itself on having a team of professional engineers and technicians with in-depth knowledge of PCB manufacturing and wireless sensor network development. This ensures that your prototype not only meets your requirements but exceeds your expectations.

C. Customization and Flexibility: Capel knows that every project is unique, so they offer customizable solutions for your PCB prototyping needs. Whether you require specific design parameters, material selections, or integration possibilities, Capel can accommodate your preferences.

d. Time and cost efficiency: With Capel’s streamlined processes and efficient workflow, you can expect fast turnaround times and cost-effective PCB prototyping solutions.

e. Quality Assurance: Capel’s quality control measures are second to none. Through rigorous testing and inspection, they ensure each prototype meets the highest industry standards, reducing the risk of design errors or inconsistencies.

5 Conclusion:

Designing a PCB prototype for a wireless sensor network is not only achievable but also critical to ensuring the success of the project. By leveraging Capel’s 15 years of experience in circuit board manufacturing, you can create rugged and reliable PCB prototypes specifically designed to meet the requirements of wireless sensor networks. With its state-of-the-art facilities, team of experts, customization options, and unwavering commitment to quality, Capel is your trusted partner in wireless sensor network development.

So if you find yourself wondering, “Can I prototype a PCB for a wireless sensor network?” remember, Capel is your go-to company with the experience, knowledge, and resources needed to make it happen. Don’t compromise on your wireless sensor network projects – choose Capel for all your PCB prototyping needs!

Post time: Oct-29-2023

Back