There are many factors to consider when designing a printed circuit board (PCB) prototype. Choosing the appropriate number of layers is an important decision that can significantly affect the functionality and complexity of the PCB. As a leading provider of PCB prototyping services, Capel is proud to offer a wide range of layer options to meet the diverse needs of our customers. Whether you require a 4-layer or 6-layer PCB, Capel has the expertise and experience to deliver high-quality prototypes to meet your specifications.

Capel is a trusted name in the PCB industry with over 15 years of experience. We have become a reliable partner for customers looking for PCB prototypes with layer counts from 1 to 30 layers (FPC Flex PCB), 2 to 32 layers (rigid-flex PCB), and even up to 60 layers (rigid PCB). Our team of experts is well-versed in the intricacies of PCB design and manufacturing, ensuring every prototype meets the highest industry standards.

Now, let’s delve deeper into the options available for prototyping a 4-layer or 6-layer PCB.

A 4-layer PCB is a popular choice for many applications because of its ability to accommodate complex circuit designs while maintaining reasonable cost and ease of manufacturing. It consists of four layers, two inner layers sandwiched between two outer layers. This configuration increases component density, improves signal integrity, and enhances thermal management. Additionally, internal ground and power planes contribute to better EMI shielding and noise reduction.

On the other hand, a 6-layer PCB offers greater design flexibility and routing possibilities. This layer count provides four inner layers, providing additional space for power planes, ground planes, and signal paths. The increased number of layers also helps reduce signal interference and crosstalk, thereby improving overall performance and reliability. Additional layers enable more complex designs, making it ideal for high-speed and high-frequency applications.

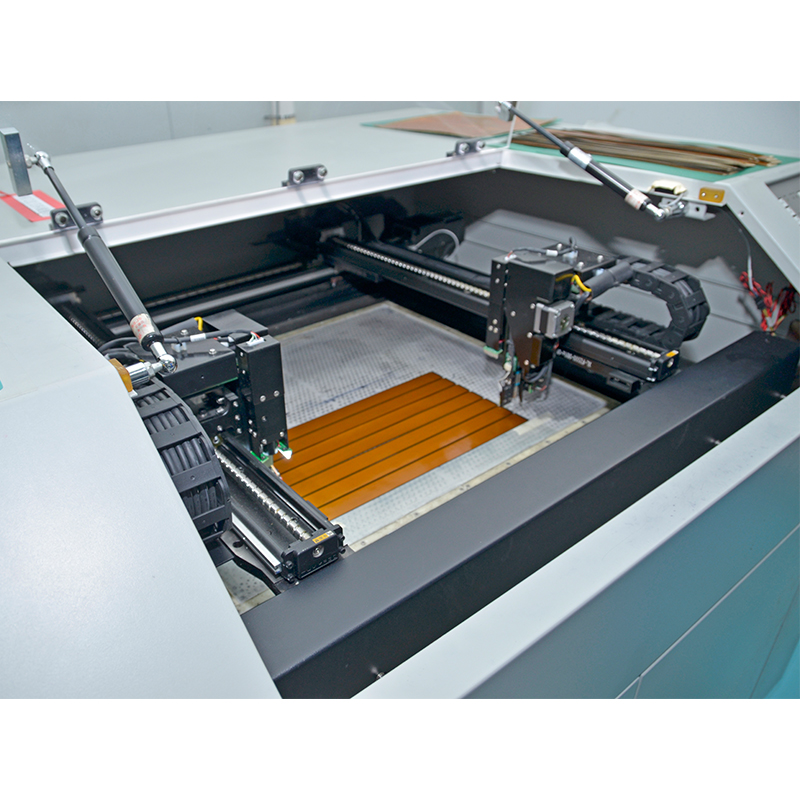

Whether you choose a 4-layer or 6-layer PCB for your prototype, Capel ensures the highest level of quality throughout the entire manufacturing process. We utilize advanced technology and state-of-the-art equipment to produce accurate and reliable PCB prototypes. Our team of skilled engineers strictly follows industry best practices and standards to ensure each prototype meets your exact specifications.

When working with Capel, you can expect exceptional service that goes beyond prototyping. We offer comprehensive design review and optimization services to help identify any potential issues and ensure your design is optimized for production. Our experienced engineers work closely with you to understand your specific requirements and provide valuable insights to improve PCB performance and manufacturability.

At Capel, we understand the importance of completing projects on time. Our streamlined production processes and efficient project management ensure the timely delivery of your prototypes. Our order quantities are flexible, from small batches to large-scale production, to meet the needs of different customers.

In short, whether you need a 4-layer or 6-layer PCB prototype, Capel is your trusted partner. With our extensive experience, advanced manufacturing capabilities, and commitment to quality, we are equipped to handle any PCB prototyping project. Contact us today to discuss your needs and find out how Capel can turn your PCB prototype vision into reality.

Key combinations: Can I prototype a 4-layer or 6-layer PCB? Capel provides PCB prototyping services and has 15 years of experience in the PCB industry, including 1-30-layer FPC flex boards, 2-32-layer soft and hard boards, and 1-60-layer hard boards.

Post time: Oct-14-2023

Back