Through-hole components, as the name suggests, have leads or pins that are inserted through a hole in the PCB and soldered to a pad on the other side. These components are widely used in the industry due to their reliability and ease of repair. So, can rigid-flex PCBs accommodate through-hole components? Let’s delve deeper into this topic to find out.However, a common question that arises when considering the use of rigid-flex PCBs is their compatibility with through-hole components.

In short, the answer is yes, rigid-flex PCBs are compatible with through-hole components. However, certain design considerations need to be considered to ensure successful integration.

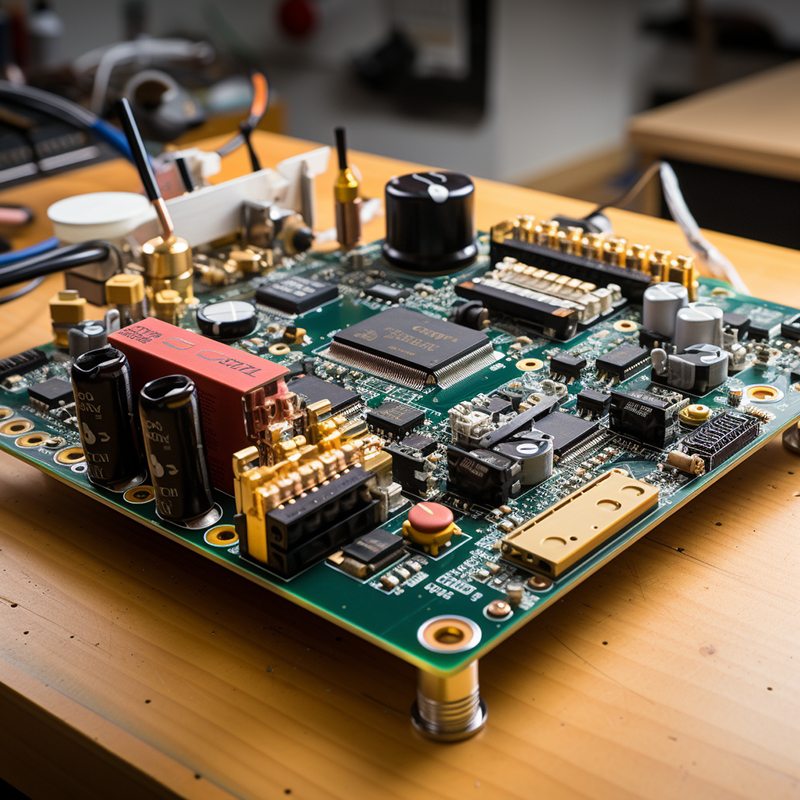

In today’s rapidly evolving technology environment, the need for electronic devices that offer higher performance in smaller form factors has become the norm. Therefore, the Printed Circuit Board (PCB) industry is forced to innovate and develop new advanced solutions to meet these needs. One solution is the introduction of rigid-flex PCBs, which combine the flexibility of flexible PCBs with the strength and durability of rigid PCBs.

Rigid-flex PCBs are popular with designers and manufacturers for their ability to increase design flexibility while reducing overall size and weight. They are used in a wide range of applications, including the aerospace, medical device, consumer electronics and automotive industries.

One of the main concerns when using through-hole components on rigid-flex PCBs is the mechanical stress that may be applied to the solder joints during assembly or use in the field. Rigid-flex PCB, as the name suggests, consists of rigid and flexible areas interconnected by plated through holes or flexible connectors. Flexible parts are free to bend or twist the PCB, while rigid parts provide stability and support to the assembly. To accommodate through-hole components, designers need to carefully select the location of the holes and ensure they are placed on a rigid part of the PCB to avoid excessive stress on the solder joints.

Another important consideration is using appropriate anchor points for through-hole components. Because rigid-flex PCBs can bend or twist, it is critical to provide additional support to prevent excessive movement and stress on the solder joints. Reinforcement can be achieved by adding stiffeners or brackets around the through-hole component to evenly distribute stress.

Additionally, designers should pay attention to the size and orientation of through-hole components. Holes should be sized appropriately to ensure a snug fit, and components should be oriented to minimize the risk of interference with PCB flex components.

It is also worth mentioning that advances in PCB manufacturing technology have made it possible to produce rigid-flex PCBs using high-density interconnect (HDI) technology. HDI enables component miniaturization and increased circuit density, making it easier to accommodate through-hole components on the flexible portion of the PCB without compromising functionality or reliability.

In summary, rigid-flex PCBs can indeed be compatible with through-hole components if certain design considerations are taken into account. By carefully selecting locations, providing adequate support, and taking advantage of advances in manufacturing technology, designers can successfully integrate through-hole components into rigid-flex PCBs without compromising performance or reliability. As technology continues to advance, the use of rigid-flex PCBs is only expected to increase, providing more opportunities for efficient, compact electronic designs.

Post time: Sep-20-2023

Back