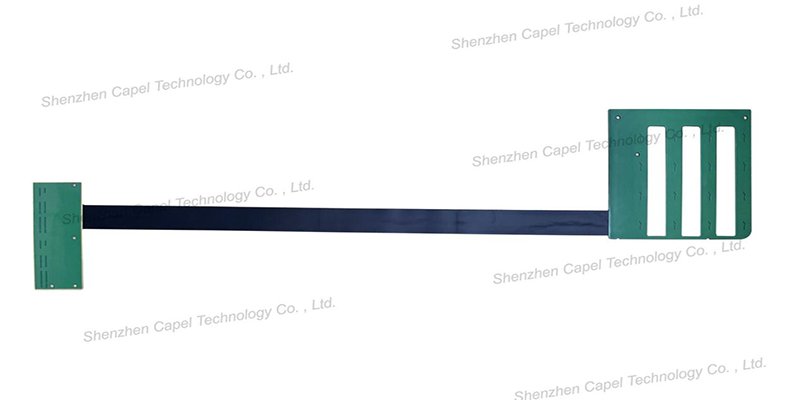

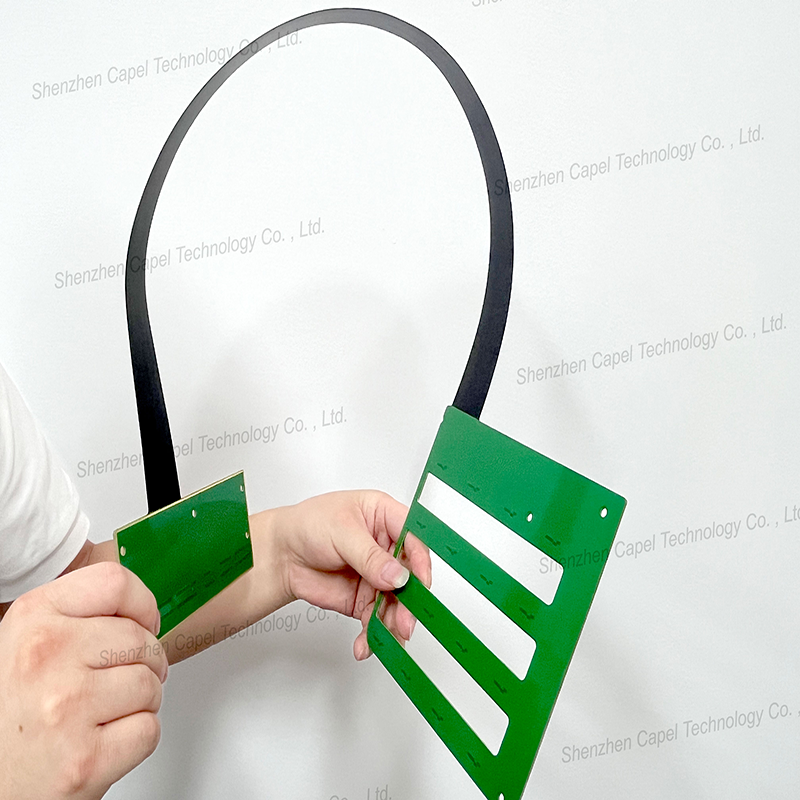

This 900 mm long rigid-flex PCB is tailored for use in large equipment, high-end electronic devices, and complex systems such as medical equipment, industrial control systems, high-end communication devices, and military products. The rigid-flex PCB seamlessly integrates the flexibility of the flexible part with the stability of the hard part through a precise lamination process, ensuring both the circuit’s flexibility and the reliability of the connection.

In terms of materials, the rigid-flex PCB utilizes high-quality polyimide (PI) as the flexible base material, combined with copper foil lamination technology to guarantee durability and electrical performance. Rigid materials like FR-4 are employed for the hard parts to meet structural strength requirements. The production process incorporates advanced vapor deposition and electroless copper plating technologies to ensure a uniform copper layer and strong adhesion, laying a solid foundation for subsequent processes such as drilling and electroplating.

The final product boasts excellent electrical performance and mechanical strength, along with good bendability and fatigue resistance, making it adaptable to various complex usage environments. Furthermore, the design flexibility of the rigid-flex PCB significantly enhances product integration and space utilization, ultimately reducing overall system costs and improving performance.

Capel's commitment to utilizing basic materials and advanced production processes ensures that our rigid-flex PCBs meet the highest standards of quality and reliability, making them an ideal choice for demanding electronic applications.

Post time: Sep-18-2024

Back