In the rapidly evolving world of electronics, the demand for high-performance PCB has never been greater. Among the various types of PCB, the 6-layer PCB stands out due to its ability to accommodate complex circuitry while maintaining a compact form factor. This article delves into the intricacies of 6L PCB, particularly those featuring blind holes, and explores the role of PCB manufacturers in delivering high-quality products with advanced surface finishes like EING.

Understanding 6L PCB

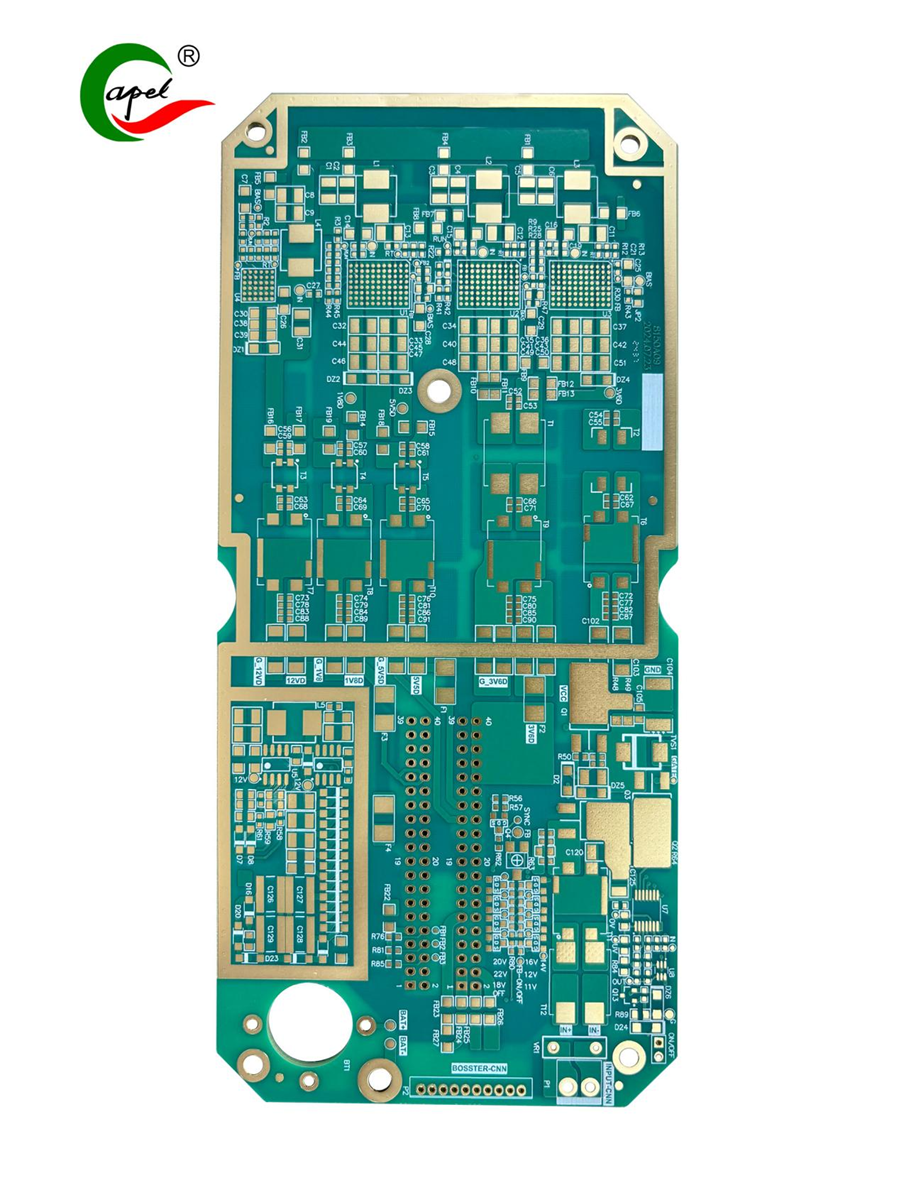

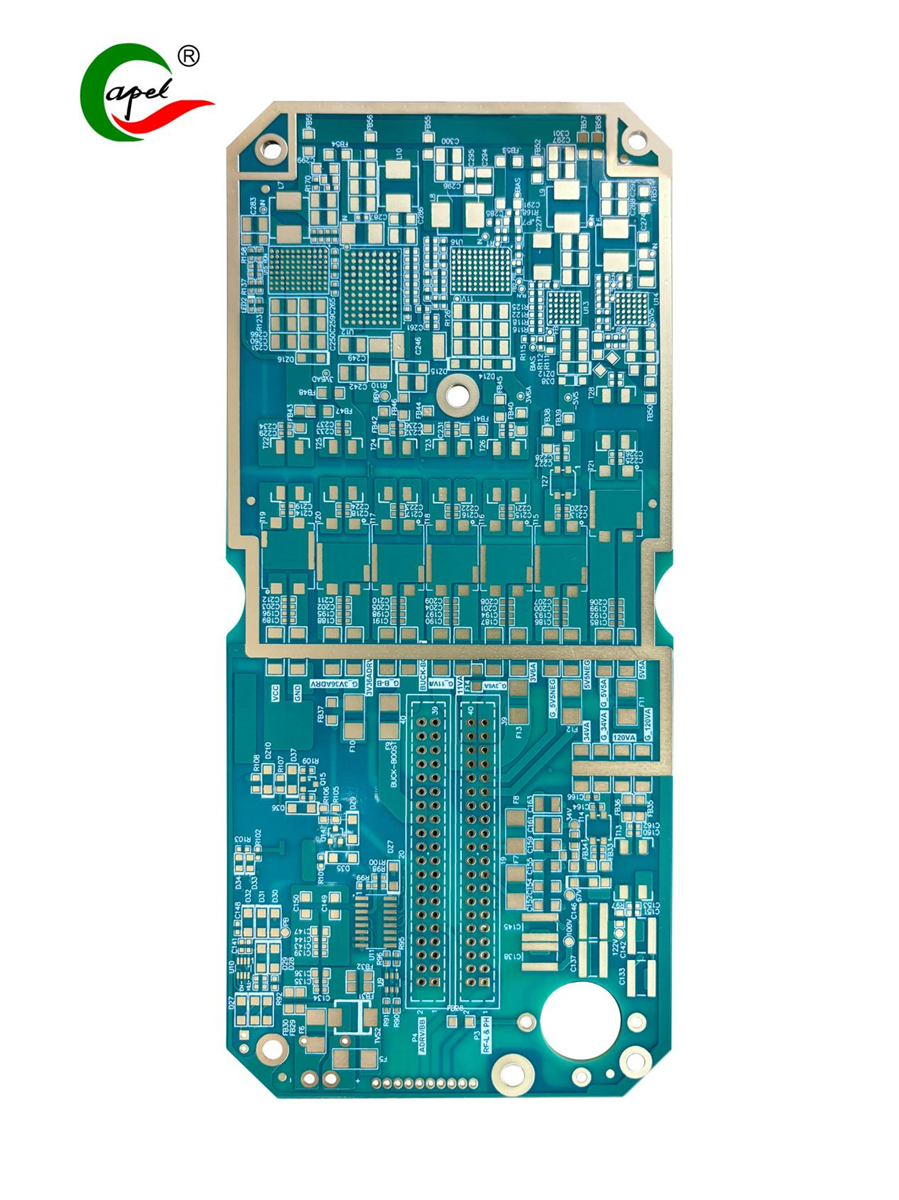

A 6-layer PCB consists of six conductive layers separated by insulating materials. This multi-layer configuration allows for increased circuit density, making it ideal for applications in telecommunications, consumer electronics, and automotive systems. The layers are typically arranged in a specific order to optimize signal integrity and minimize electromagnetic interference (EMI).

The construction of a 6L PCB involves several critical processes, including layer stacking, lamination, drilling, and etching. Each step must be executed with precision to ensure the final product meets the stringent requirements of modern electronic devices.

The Importance of Blind Holes

One of the innovative features that can be incorporated into a 6L PCB is the use of blind holes. A blind hole is a hole that does not go all the way through the PCB; it connects one or more layers but is not visible from the opposite side. This design element is particularly beneficial for routing signals and power connections without compromising the board’s overall integrity.

Blind holes can help reduce the board’s footprint, allowing for more compact designs. They also facilitate better thermal management by providing pathways for heat dissipation. However, the manufacturing of blind holes requires advanced techniques and precision, making it essential to partner with a reputable PCB manufacturer.

The Role of PCB Manufacturers

Choosing the right PCB manufacturer is crucial for achieving high-quality 6L PCBs with blind holes. A reliable manufacturer will have the necessary expertise, technology, and quality control measures in place to ensure that the final product meets industry standards.

When selecting a PCB manufacturer, consider the following factors:

Experience and Expertise: Look for manufacturers with a proven track record in producing multi-layer PCBs, particularly those with blind hole technology.

Technology and Equipment: Advanced manufacturing processes, such as laser drilling and automated optical inspection (AOI), are essential for creating precise blind holes.

Quality Assurance: A reputable manufacturer will implement rigorous quality control measures, including testing for electrical performance and mechanical integrity.

Customization Options: The ability to customize designs, including the size and placement of blind holes, is vital for meeting specific project requirements.

Resin Plug Holes: A Solution for Blind Holes

To enhance the performance of 6L PCBs with blind holes, manufacturers often use resin plug holes. This technique involves filling the blind holes with a resin material, which serves multiple purposes:

Electrical Isolation: Resin plug holes help prevent electrical shorts between layers, ensuring reliable performance.

Mechanical Stability: The resin adds structural integrity to the PCB, making it more resistant to mechanical stress.

Surface Finish: EING

The surface finish of a PCB is a critical factor that influences its performance and reliability. EING is a popular choice among manufacturers due to its unique properties. This finish involves a two-step process: electroless nickel plating followed by immersion gold plating.

Benefits of EING:

Solderability: EING provides a flat, even surface that enhances solderability, making it easier to attach components during assembly.

Corrosion Resistance: The gold layer protects the underlying nickel from oxidation, ensuring long-term reliability in various environmental conditions.

Flatness: The smooth surface of EING is ideal for fine-pitch components, which are increasingly common in modern electronics.

Compatibility: EING is compatible with various PCB materials and can be applied to boards with blind holes, ensuring a seamless integration of design elements.

Post time: Oct-14-2024

Back