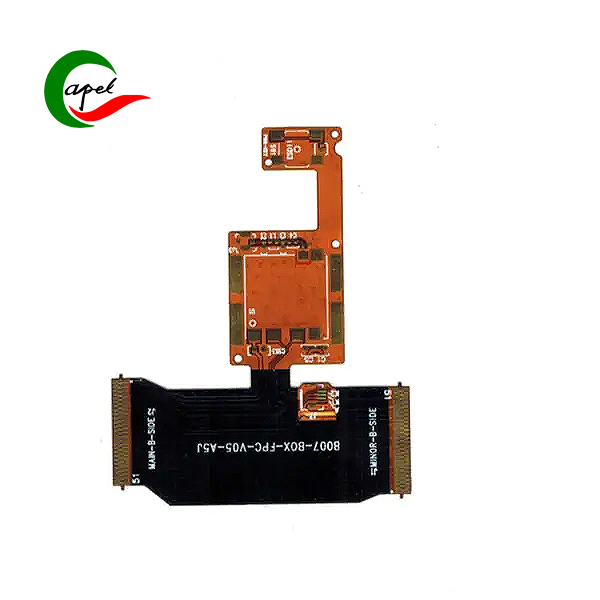

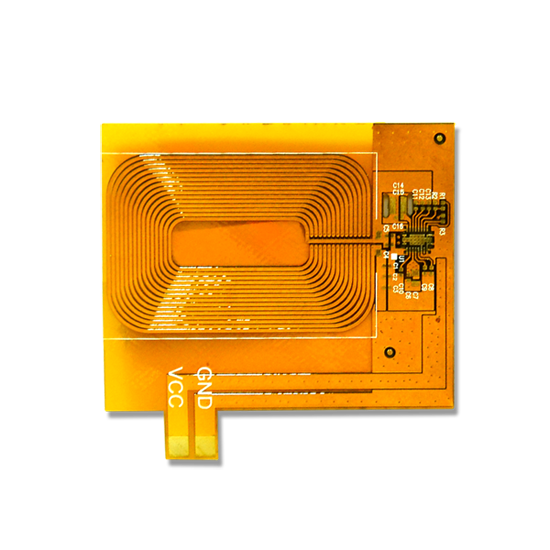

mobile phone rigid flex PCB | smartphone flex PCB circuit board

What are the most difficult problems that customers of mobile phone antenna fpc flexible circuit boards need to solve?

-Capel with 15 years of professional technical experience-

High-frequency signal transmission: Ensure that the circuit board can effectively transmit high-frequency signals to avoid attenuation and signal interference.

Anti-interference ability: Ensure that the circuit board is not affected by other electronic devices or electromagnetic interference during the use of the mobile phone.

Size and weight: The size and weight of the circuit board need to be considered to ensure it fits the design requirements of the phone.

Flexibility and durability: Ensure that the flexible circuit board is not easily damaged when bent or squeezed, and has long-term stable performance.

Cost-Effectiveness: Customers may face challenges that require a balance between cost and performance.

Manufacturing: Including efficient batch production and assembly processes, as well as technology to ensure circuit board quality and consistency.

Material selection: Consideration needs to be given to high-performance materials suitable for flexible circuit boards and to ensure supply chain reliability. Environmental protection and sustainability: Ensure that the production process of circuit boards meets environmental requirements and that the disposal of waste circuit boards can achieve sustainability.

Testing and verification: Including effective testing and verification of flexible circuit boards to ensure compliance with specifications and performance requirements.

Technical Support: Customers may need to provide technical support and solutions to address challenges and problems in practical applications.

High-frequency signal transmission: When designing PCB antennas flexible PCB, engineers will use the classic design principles of high-frequency transmission lines, such as microstrip lines. Through appropriate characteristic impedance matching and wiring design, ensure that high-frequency signals can be transmitted on the circuit board with minimal attenuation. Engineers will use simulation software to perform frequency domain and time domain analysis to verify the performance of signal transmission. For example, when engineers design flexible circuit boards, they optimize line width, dielectric height, and material properties through simulation analysis to ensure that the transmission performance at a specific frequency meets the requirements.

Anti-interference ability: When solving the problem of anti-interference ability, engineers will use technologies such as shielding design and ground wire processing. By adding appropriate shielding layers and ground wires to the mobile phone antenna flex PCB, the interference of other electromagnetic signals on the mobile phone antenna signal can be effectively reduced. Engineers may also use simulation and actual measurement to verify the anti-interference performance of the circuit board to ensure its stability and reliability. For example, in actual projects, engineers may conduct electromagnetic compatibility tests on mobile phone flexible circuit boards to verify their anti-interference capabilities in actual environments.

Size and weight: When designing a flex PCB for a mobile phone antenna, engineers need to take into account the design requirements of the mobile phone and consider size and weight restrictions. By using technologies such as flexible substrates and fine wiring, the size and weight of circuit boards can be effectively reduced. For example, engineers can choose a flexible substrate with a smaller thickness and flexibly lay out circuits according to the specific design requirements of mobile phone antennas to reduce the size and weight of the circuit board.

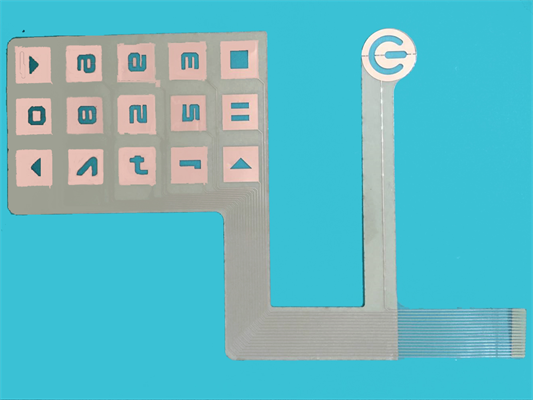

Flexibility and durability: To improve the flexibility and durability of flexible circuit boards, engineers will use advanced flexible substrates and connection processes. For example, choose flexible materials with good bending properties and use appropriate connector designs to ensure that the circuit board is not easily damaged under frequent bending or extrusion. Engineers may evaluate the board's flexibility and durability through experimental testing and reliability verification.

Cost-effectiveness: Engineers optimize design and material selection to balance cost and performance. For example, select substrates with excellent performance and moderate cost, reduce material usage through optimized wiring design, and adopt efficient manufacturing processes and automated equipment to improve production efficiency, thereby reducing costs while ensuring performance. In actual projects, engineers may use cost analysis tools, such as DFM (Design for Manufacturing) software, to evaluate the cost-effectiveness of design solutions and provide customers with the best solution.

Manufacturing: Engineers need to design reasonable mass production and assembly processes to ensure the quality and consistency of circuit boards. For example, during the manufacturing process, engineers may use SMT (Surface Mount Technology) and automated assembly equipment to ensure high-quality circuit board production. Engineers may also design corresponding testing and inspection processes to effectively monitor the quality of circuit boards and ensure that they meet specifications.

Material selection: Engineers need to select high-performance materials suitable for mobile phone antenna flexible circuit boards and ensure the reliability of the supply chain. For example, when selecting materials, engineers may consider factors such as dielectric constant, dielectric loss, and bending properties of flexible substrates, and negotiate with suppliers to ensure the availability and stability of materials. Engineers may conduct material testing and comparisons to select the most suitable material solution.

Environmental protection and sustainability: Engineers will adopt environmentally friendly manufacturing processes and sustainable material selection to ensure that the production process of FPC antenna flex PCB meets environmental requirements. For example, consider the environmental performance of materials during the design stage, select materials that comply with RoHS directives, and design recyclable manufacturing processes. Engineers may also work with suppliers to establish supply chain systems that meet sustainability goals.

Testing and verification: Engineers will conduct various tests and verifications on mobile phone antenna Fpc to ensure that they meet specifications and performance requirements. For example, high-frequency test equipment is used for signal transmission performance testing, and electromagnetic compatibility testing equipment is used for anti-interference performance testing to verify the performance of the circuit board. Engineers may also use reliability testing equipment to verify the durability and stability of circuit boards.

Technical support: Engineers will provide professional technical support and solutions when customers face practical application challenges. For example, if a customer encounters a performance problem in the application of a mobile phone antenna flexible circuit board, the engineer may conduct an in-depth analysis of the cause of the problem, propose an improvement plan, and provide support and assistance in practical applications. Engineers may provide customers with targeted solutions through a variety of methods, such as remote video support, on-site technical guidance, etc.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

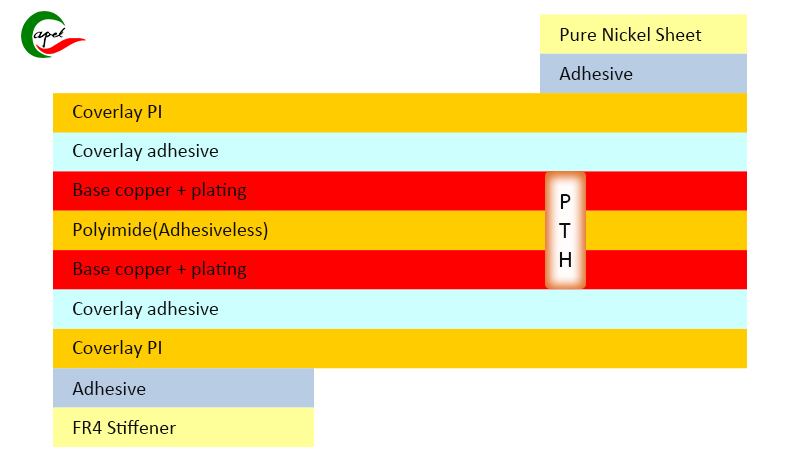

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel manufactures customized high-precision Rigid Flexible Circuit Board / Flexible PCB / HDI PCB with 15 years of experience with our professionalism

2 Layer Flexible PCB Boards Stackup

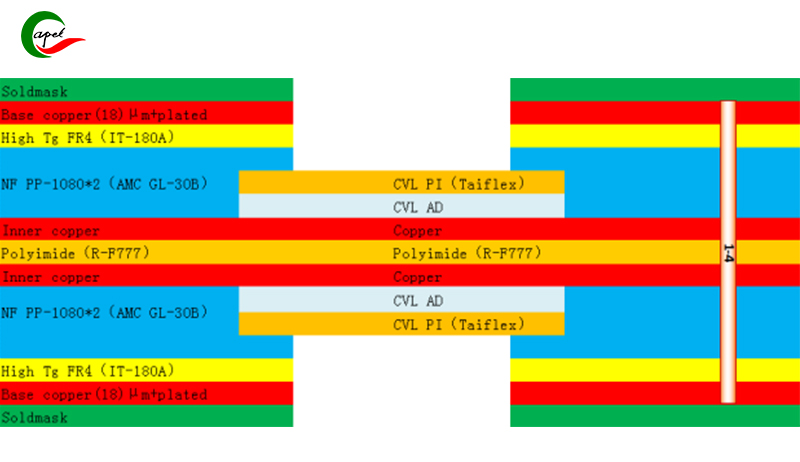

4 Layer Rigid-Flex PCB Stackup

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel provide customers customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

.jpg)