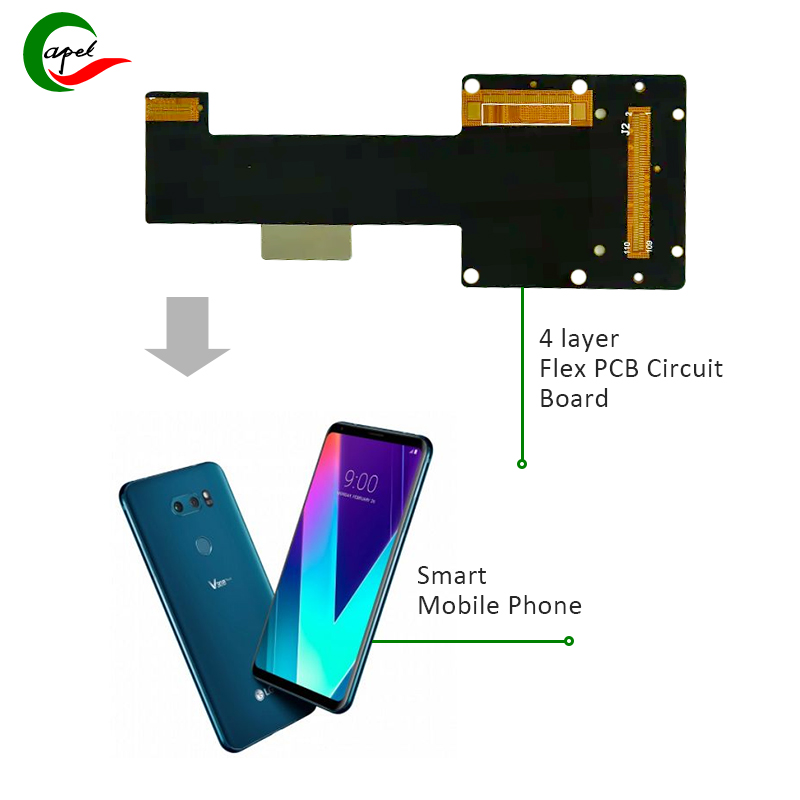

Mobile Phone Flex PCB | Smartphone PCB Motherboard | Cell Phone Circuit Board

Capel flexible circuit board manufacturer-solve cutting-edge problems for mobile phone manufacturers

-Capel with 15 years of professional technical experience-

In the mobile phone manufacturing industry, there is an increasingly urgent need for thinner, lighter and more flexible designs. To meet this demand, mobile phone manufacturers need to find partners who can provide innovative solutions. Capel flexible circuit board manufacturer has successfully solved a series of cutting-edge problems for mobile phone customers with its excellent technology and professional capabilities.

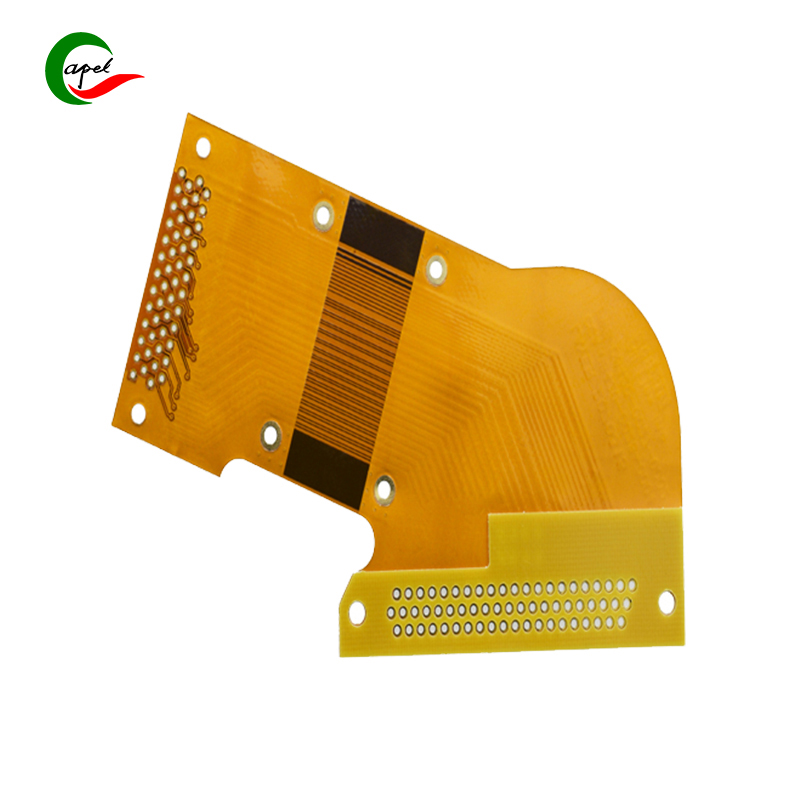

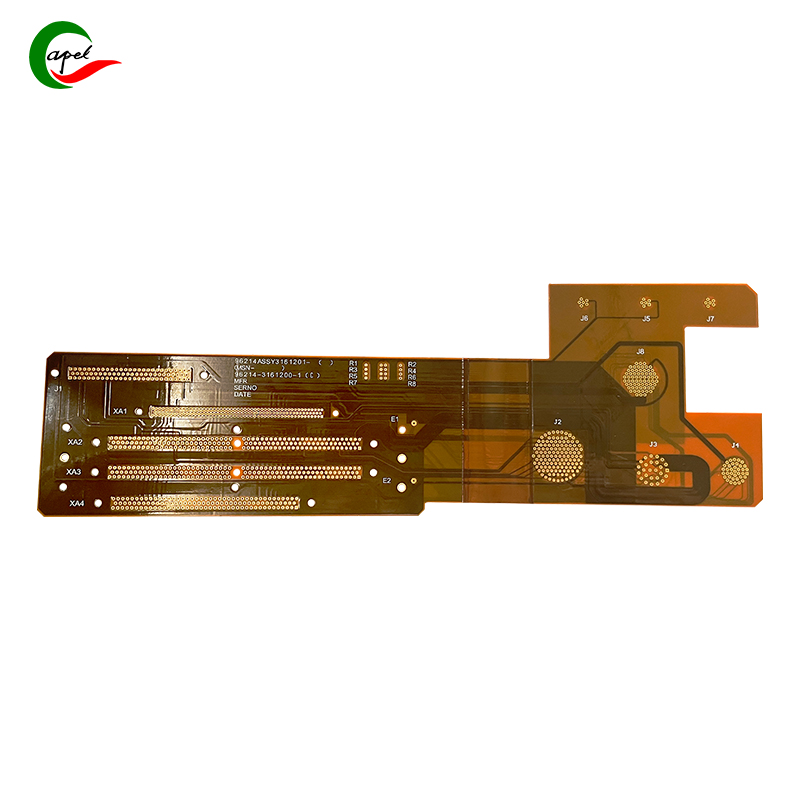

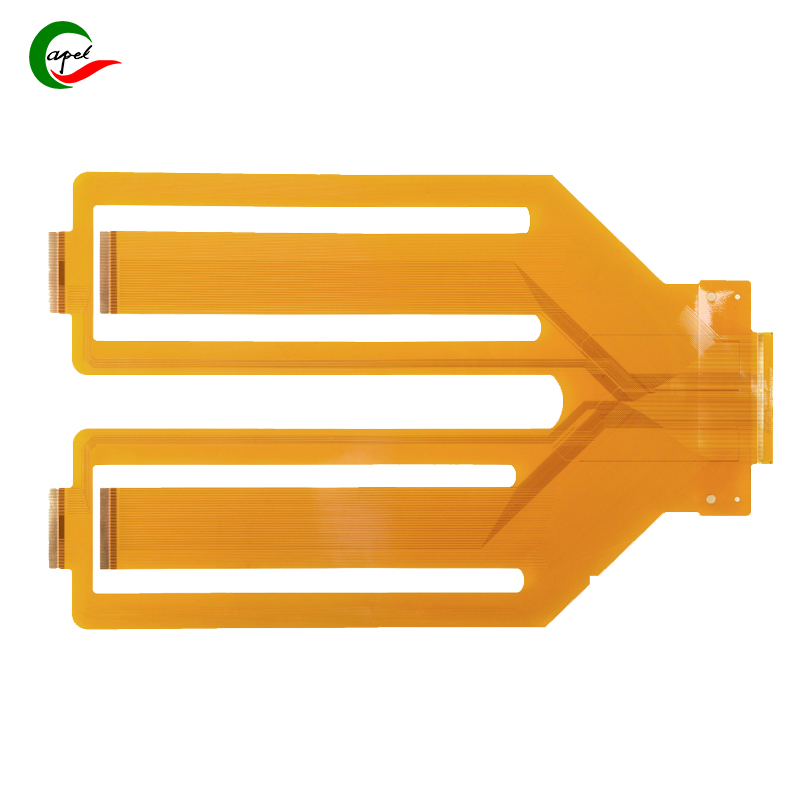

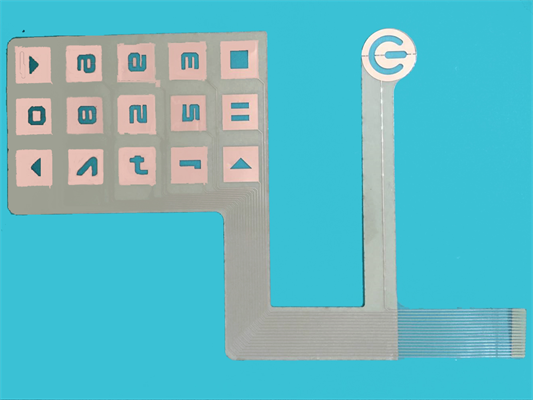

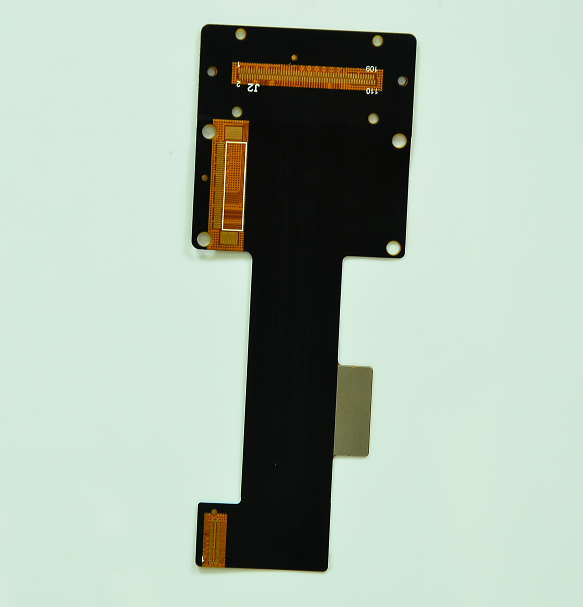

Multifunctional design: Capel flexible circuit board manufacturer provides mobile phone customers with a 4-layer flexible PCB board solution, allowing mobile phone manufacturers to implement more functions and connections in a limited space. Compared with traditional rigid PCB boards, the bending and flexibility of flexible PCB boards make the internal structure design of mobile phones more diverse, while improving the integration of functions and meeting the multifunctional design needs brought about by iterative updates of mobile phones.

Vibration resistance and durability: By introducing Capel flexible circuit boards, mobile phone manufacturers have achieved higher resistance to earthquakes and vibrations and durability, effectively reducing the problems of internal connection failure and breakage in mobile phones. This can improve the overall reliability and service life of mobile phones, while improving user experience, allowing consumers to use their mobile phones with confidence without worrying about failures caused by external impacts.

Lightweight design and battery capacity optimization: Capel flexible circuit board manufacturer's solutions help mobile phone manufacturers achieve lightweight design and optimize internal space layout to achieve greater battery capacity. This innovative design reduces the overall weight of the mobile phone and extends the battery life of the mobile phone, making the mobile phone more portable and durable.

In the highly competitive environment of the mobile phone industry, Capel flexible circuit board manufacturer not only solves many cutting-edge problems for mobile phone customers with its technology and professional capabilities, but also brings competitive advantages and innovation power to mobile phone manufacturers. We look forward to Capel flexible circuit board manufacturers continuing to provide more innovative solutions to mobile phone manufacturers in the future, bringing more possibilities to the mobile phone industry.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel manufactures customized high-precision Rigid Flexible Circuit Board / Flexible PCB / HDI PCB with 15 years of experience with our professionalism

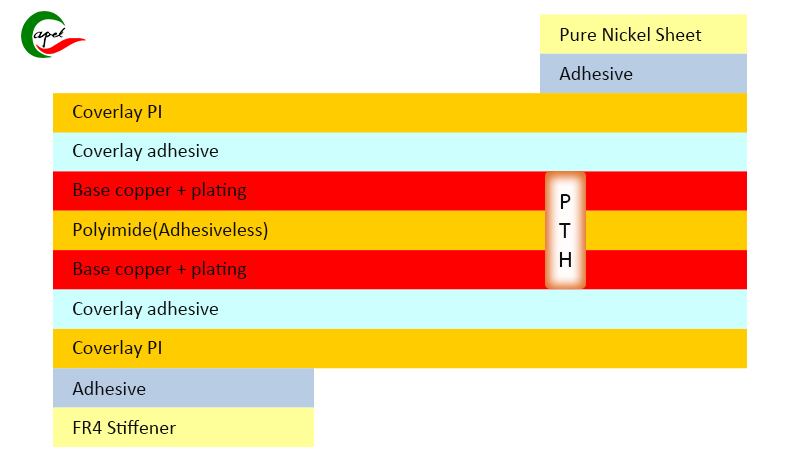

2 Layer Flexible PCB Boards Stackup

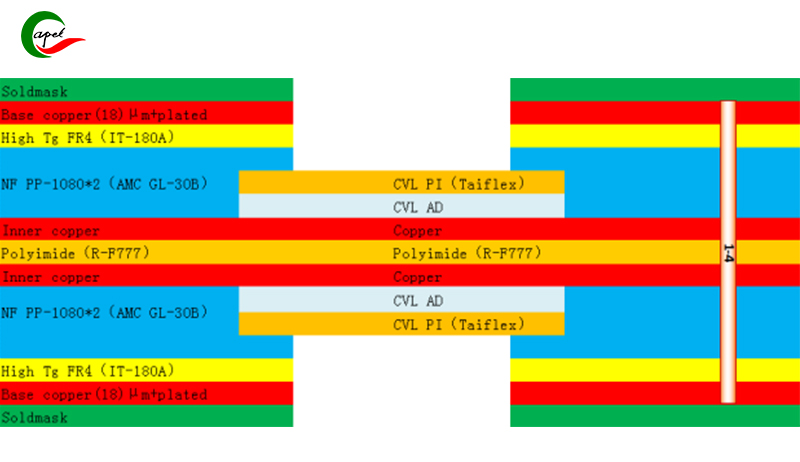

4 Layer Rigid-Flex PCB Stackup

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel provide customers customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

.jpg)