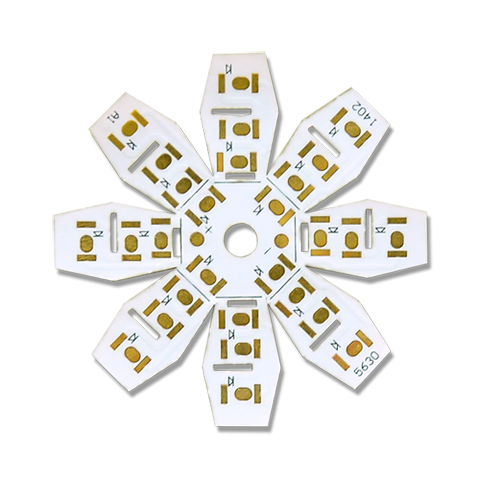

LED Rigid Flex PCB | LED PCB Manufacturing | LED Flex Circuit Board

Customers usually care about the following issues during the LED PCB board design and manufacturing process:

-Capel with 15 years of professional technical experience-

Question: How to ensure optimal circuit layout in LED PCB circuit design? Solution: Circuit board engineers can use professional software for layout and routing to minimize circuit interference and optimize circuit performance.

Question: How to ensure that the LED Light PCB board design meets the thermal management needs of the product? Solution: Engineers can use thermally conductive materials (such as aluminum substrates) and heat sink designs to ensure that LED components are effectively dissipated and improve product reliability and performance.

Question: How to choose suitable materials for LED printed circuit boards? Solution: Engineers can select appropriate materials based on the product's environmental conditions and expected performance, such as FR-4 fiberglass boards, metal substrates, etc.

Question: How to ensure that the electrical performance and EMI/EMC of LED light circuit boards comply with standards? Solution: Engineers can conduct electromagnetic compatibility testing, take shielding measures, and use filters and other methods in the design to ensure that the circuit complies with relevant standards.

Question: How does multi-layer PCB for LED ensure durability and reliability? Solution: Engineers can perform reliability analysis such as MTBF (Mean Time Between Failure) calculations and adopt appropriate tests and materials to improve the durability of the Led Flex Pcb board.

Question: How to ensure that the optical layout meets the effect requirements? Solution: Engineers can use optical software to perform optical simulations and optimize the optical layout to meet the lighting effect requirements of the product.

Question: How to ensure that the manufacturing cost of LED strip flexible PCB is controlled within a reasonable range? Solution: Engineers can conduct DFM (design for manufacturing) reviews, optimize designs to reduce manufacturing costs, and select appropriate manufacturing processes and processes.

Question: How to carry out mass production and process verification of aluminum led rigid flex PCB? Solution: Engineers can choose reliable manufacturers for sample manufacturing and verification, and conduct process review and verification before mass production.

Question: How to ensure the maintainability and repairability of smd led pcb board? Solution: Engineers can design simple and effective circuit structures and component layouts to facilitate later maintenance and repairs.

Question: How to ensure that LED strip rigid-flex PCB complies with relevant regulatory standards and environmental protection requirements? Solution: Engineers can select materials that meet environmental requirements and certification standards, and conduct environmental certification and testing to ensure that the LED PCB complies with relevant regulations and standards.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

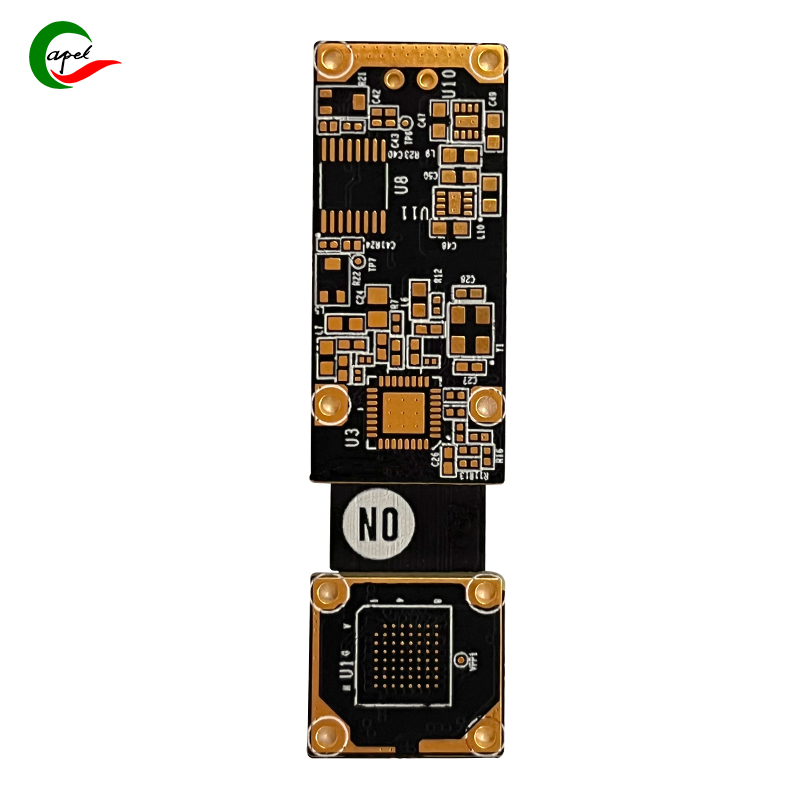

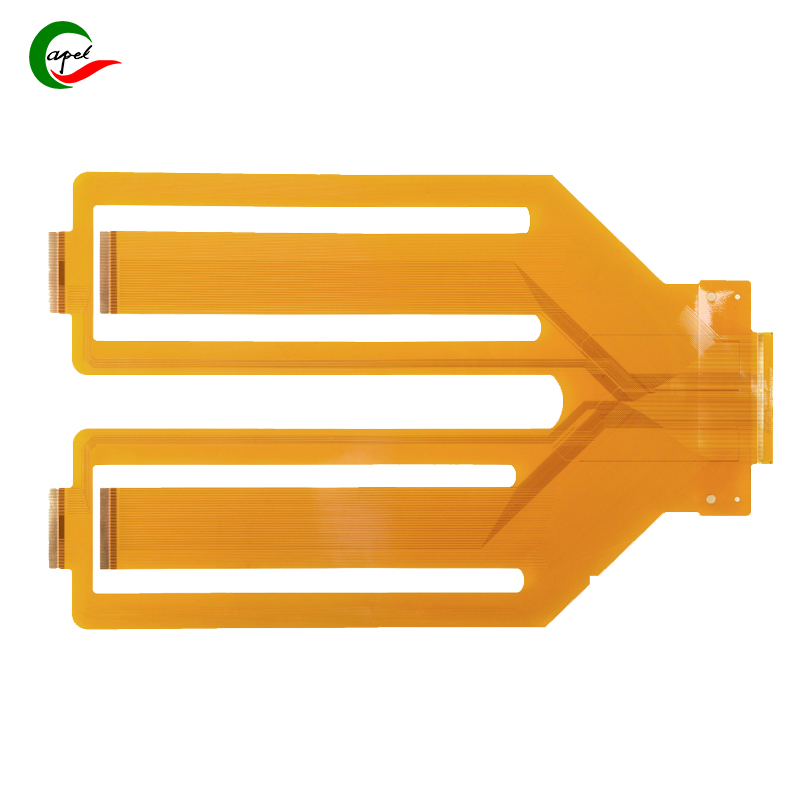

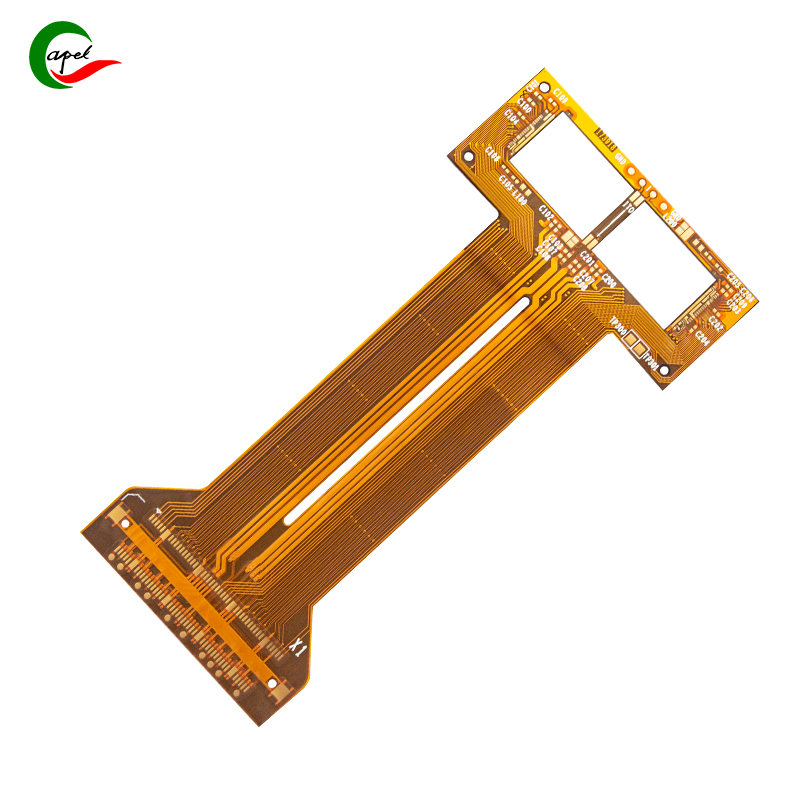

Capel manufactures customized high-precision Rigid Flexible Circuit Board / Flexible PCB / HDI PCB with 15 years of experience with our professionalism

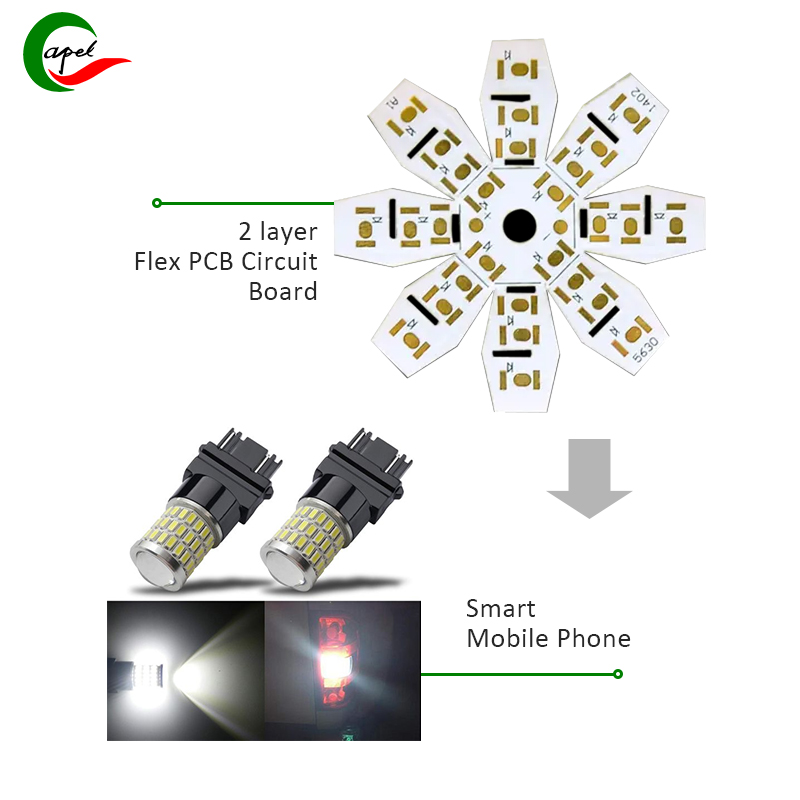

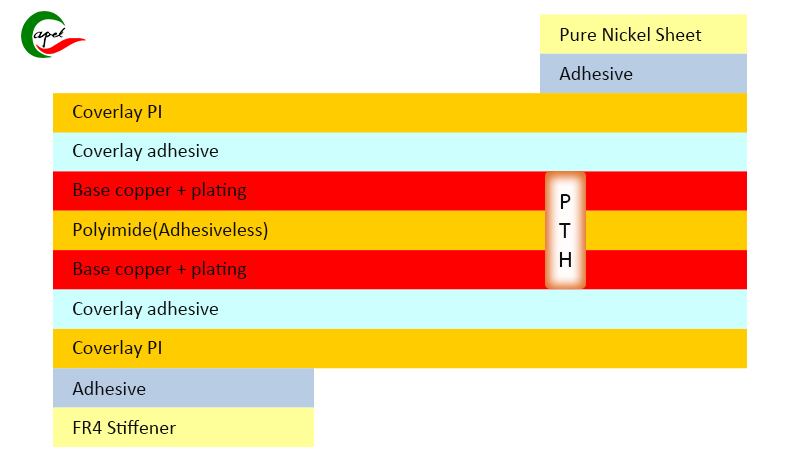

2 Layer Flexible PCB Boards Stackup

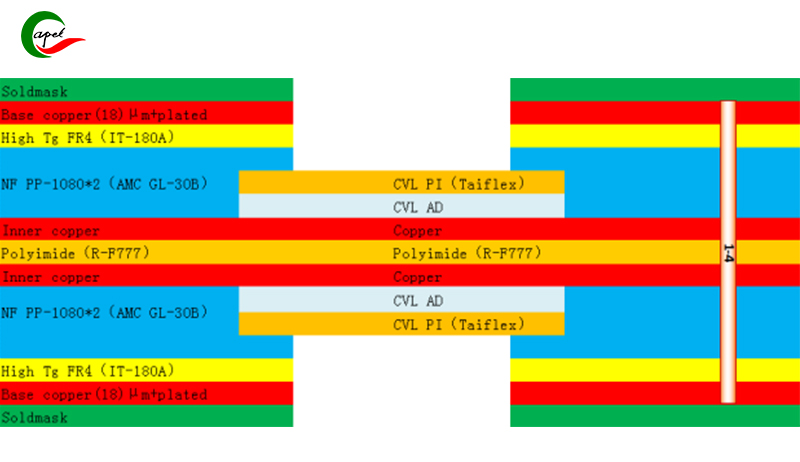

4 Layer Rigid-Flex PCB Stackup

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel provide customers customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.