Flexible PCB Manufacturing

Kaboer's 15-year flexible circuit board technology expert team

-With our deep expertise and experience, we can meet the specific requirements of our customers in terms of layer count, precision, and flexibility.

-well-versed in flex pcb manufacturing,understand the importance of high precision in flexible circuits boards

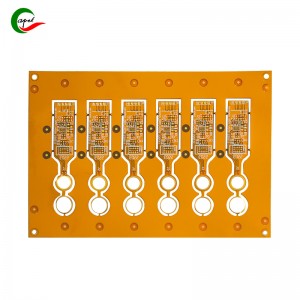

Support customized 1-30 layer high-precision flexible pcb circuit board

-advanced technology, equipment, and processes to ensure accurate and reliable production. Our attention to detail, stringent quality control measures, and comprehensive testing help us deliver high-quality flexible PCBs that meet the highest industry standards.

-

14 layer FPC Flexible Circuit Boards

14 layer FPC Flexible Circuit Boards

-

Single-Side Flexible Boards

Single-Side Flexible Boards

-

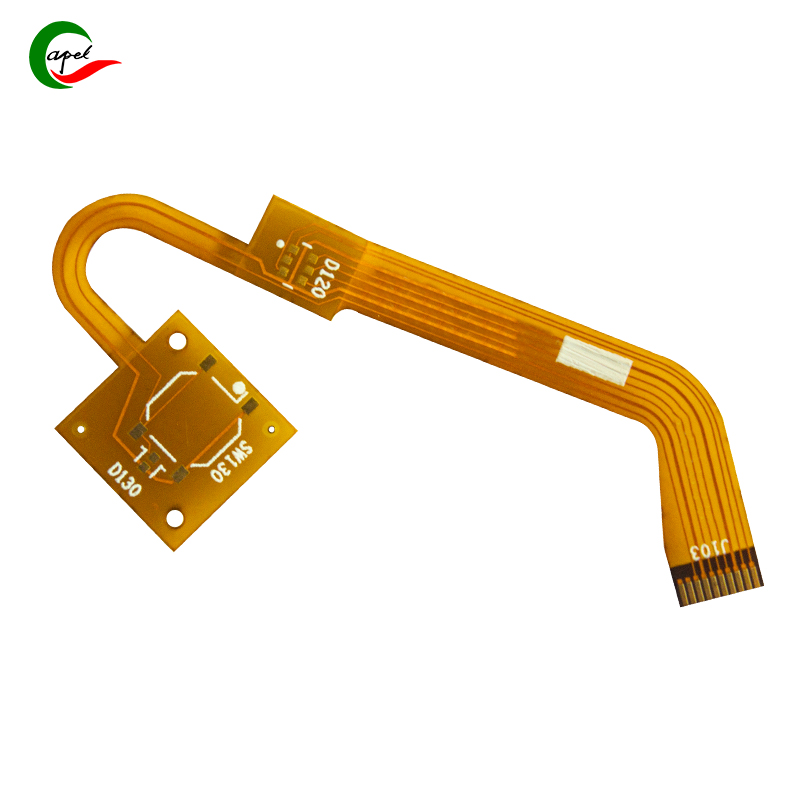

Single Layer flexible pcb

Single Layer flexible pcb

-

8 layer Flex Board Pcb

8 layer Flex Board Pcb

-

12 layer FPC Flexible PCBs

12 layer FPC Flexible PCBs

-

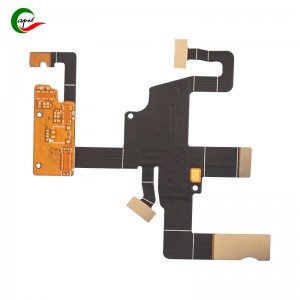

2 layer flexible pcb

2 layer flexible pcb

-

2 layer flexible pcb

2 layer flexible pcb

-

4 layer Flex PCB Circuit Board

4 layer Flex PCB Circuit Board

Provide reliable solutions for customers in the wearable devices, medical equipment, aerospace and defense systems, automotive systems, consumer electronics, industrial automation, and telecommunications.

-Customized flexible PCBs that meet their specific requirements;

-Depending on your industry-specific needs, we can provide flexible PCBs with specialized materials such as high-temperature resistant materials for automotive and aerospace applications, as well as medical-grade materials for medical device applications. We also keep updated with the latest flexible PCB manufacturing technologies to meet the evolving demands of these industries.

-

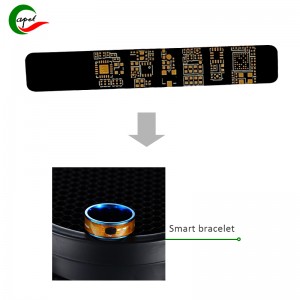

4 layer Flex PCB boards are applied to Smart Bracelet

4 layer Flex PCB boards are applied to Smart Bracelet

-

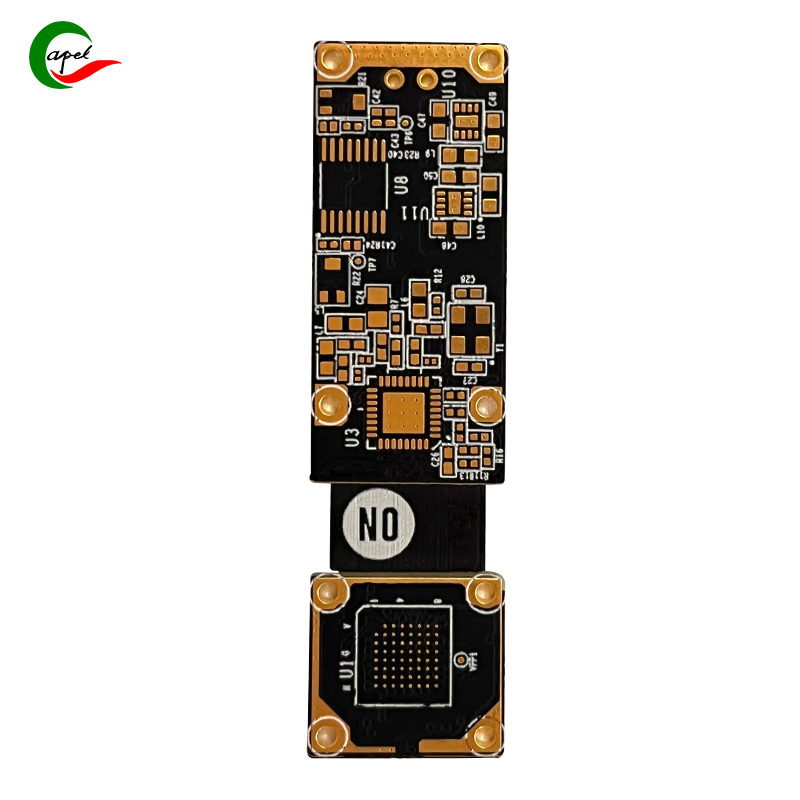

4 layers and 1 level Rigid-Flex Circuit Boards for Ventilator Medical Devices

4 layers and 1 level Rigid-Flex Circuit Boards for Ventilator Medical Devices

-

4 layer FPC Flexible PCB Boards are applied to PlayStation Gaming Device

4 layer FPC Flexible PCB Boards are applied to PlayStation Gaming Device

-

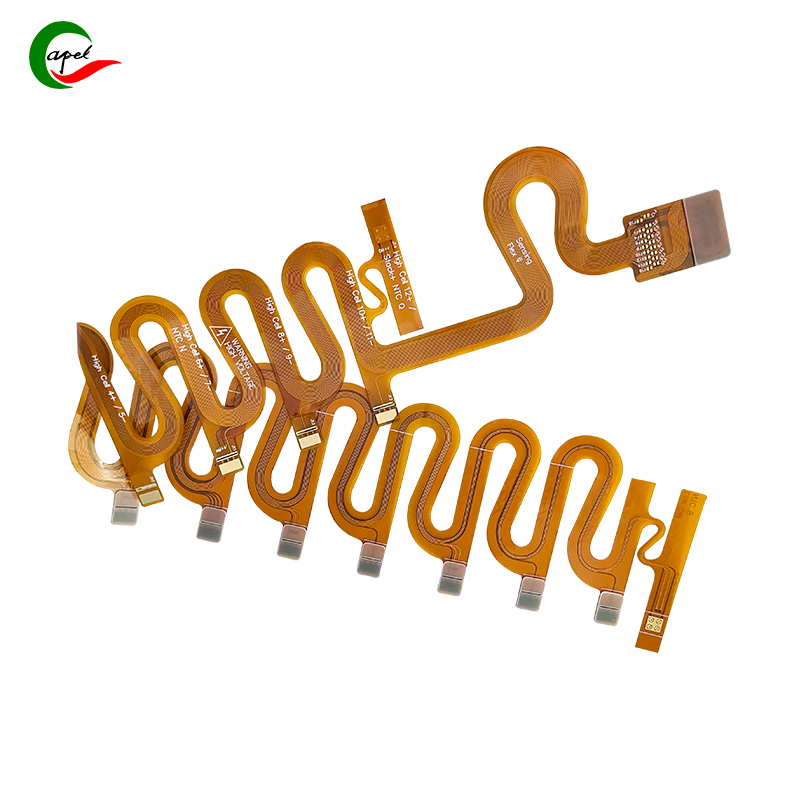

2 Layer Pcb Stackup Flex Circuit applicated in Aerospace Aviation.

2 Layer Pcb Stackup Flex Circuit applicated in Aerospace Aviation.

-

4 layer Rigid-Flex PCB Boards for Bluetooth Hearing Aid

4 layer Rigid-Flex PCB Boards for Bluetooth Hearing Aid

-

Aesthetic Instrument Medical Device

Aesthetic Instrument Medical Device

-

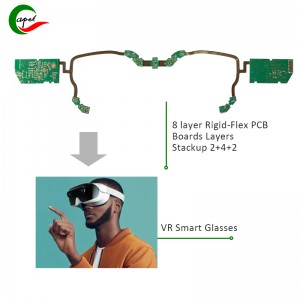

8 layer Rigid-Flex PCB Boards for VR Smart Glasses

8 layer Rigid-Flex PCB Boards for VR Smart Glasses

-

2 layer Flexible Printed Circuits are applied to Communication Electronics

2 layer Flexible Printed Circuits are applied to Communication Electronics

Turkey Flexible PCB Assembly

Provide expertise and assistance during the design phase, helping customers optimize their designs for functionality, reliability, and cost-effectiveness;

Being able to produce small quantities of flexible PCB prototypes in a timely manner, allowing customers to evaluate and validate their designs before proceeding with mass production;

Maintain detailed documentation throughout the assembly process, including bills of materials (BOMs), assembly instructions, and test records;

On-time delivery(Kaboer has efficient production planning, effective resource management, and close coordination with customers throughout the manufacturing process.);

Address any concerns or issues that may arise post-delivery and provide prompt technical support or warranty services if required.

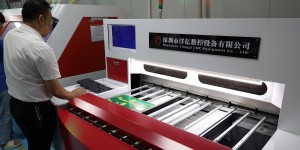

Mass Production for Flex PCB Board

Automatic Target Shooting

Flexible PCB Fabrication Advantages

Fully automated and high-precision production equipment

-minimize human errors, improve efficiency, and enhance the overall quality of our flexible PCBs.

Monthly production capacity reaches 80,000 square meters

-manage high-volume orders and meet tight production schedules. Whether you require small or large quantities, we can fulfill your order requirements promptly and efficiently.

Continuous innovation of excellent and advanced process technology

-We prioritize innovation and constant improvement in our flexible PCB fabrication process,continuously explores and adopts new and advanced technologies,provide you with cutting-edge solutions and ensure that your flexible PCBs meet the latest technical standards.

-Optimize the manufacturing process to improve efficiency and reduce costs,minimize material waste, shorten lead times, and offer cost-effective solutions to our customers.

-

Automatic reinforcement

Automatic reinforcement

-

Driiling

Driiling

-

DES Line

DES Line

-

Automatic VCP

Automatic VCP

-

CNC

CNC

-

LDI Exposure

LDI Exposure

-

Automatic V-cutting

Automatic V-cutting

-

Laser Driiling

Laser Driiling

Flexible PCB Production Capability

|

Category

|

Process Capability

|

Category

|

Process Capability

|

|

Production Type

|

Single layer FPC flex PCB

Double layers FPC flec PCB

Multilayer FPC

Aluminum PCB

Rigid-Flex PCB

|

Layers

Number

|

1-30 layers FPC Flexible PCB

2-32 layers Rigid-FlexPCB

1-60 layers Rigid PCB

HDI Boards

|

Max

Manufacture

Size

|

Single layer FPC 4000mm

Doublelayers FPC 1200mm

Multi-layers FPC 750mm

Rigid-Flex PCB 750mm

|

Insulating

Layer

Thickness

|

27.5um /37.5/ 50um /65/75um/100um /125um / 150um

|

Board

Thickness

|

FPC0.06mm-04mm

Rigid-Flex PCB025-60mm

|

Tolerance of

PTH Size

|

+0.075mm

|

Surface

Finish

|

Immersion Gold/mmersion/

Silver/Gold Plating/Tin Plating/OSP

|

Stiffener

|

FR4 /PI/ PET /SUS /PSA/Alu

|

Semicircle

Orifice Size

|

Min 0.4mm

|

Min Line Space width

|

0.045mm/0.045mm

|

Thickness

Tolerance

|

+0.03mm

|

Impedance

|

500-1200

|

Copper Foil

Thickness

|

9um/12um /18um /35um /70um/100um

|

Impedance

Controlled

Tolerance

|

+10%

|

Tolerance ot

NPTH Size

|

+0.05mm

|

The Min Flush Width

|

0.80mm

|

|

Min Via Hole

|

0.1mm

|

lmplement

Standard

|

GB/IPC-650/PC-6012IPC-01311/IPC-601311

|

|

Certifications

|

ULand ROHS

5014001:2015

IS0 9001:2015

IATF16949:2016

|

Patents

|

model patents

invention patents

|

Quality Control for Flexible PCB Production

Complete quality control system

- We have implemented a comprehensive quality control system to ensure the highest standards in flexible PCB production(material inspection, process monitoring, product testing, and evaluation)

Our operation is ISO 14001:2015 , ISO 9001:2015, IATF16949:2016 certified

-our commitment to quality management, environmental sustainability, and continuous improvement,our dedication to delivering reliable and high-quality flexible PCBs.

Our products are UL and ROHS marked

-ensures that our flexible PCBs meet safety standards and comply with industry regulations,free from hazardous substances,make them environmentally friendly and safe for use in various applications

Obtained more than 20 utility model patents and invention patents

-our focus on developing unique and creative solutions in flexible PCB manufacturing,Our commitment to innovation ensures that you receive cutting-edge products that meet your specific requirements.

-

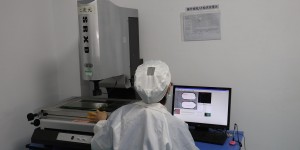

Two-dimensional test

Two-dimensional test

-

E-Testing

E-Testing

-

Impedance Tester

Impedance Tester

-

AOI

AOI

-

X-RAY Inspection

X-RAY Inspection

-

Flying Probe Test

Flying Probe Test

-

Halogen Tester

Halogen Tester

-

Flying Probe Test

Flying Probe Test

Quick Turn Flexible PCB Prototyping

24-hour non-stop flexible circuit board prototype production service

Delivery for small batch orders usually takes 5-7 days

Mass production delivery usually takes 10-15 days

|

Production

|

Number of layers

|

Delivery time (business days)

|

|

Samples

|

Mass Production

|

|

FPC

|

1L

|

3

|

6-7

|

|

2L

|

4

|

7-8

|

|

3L

|

5

|

8-10

|

|

For FPC flexible PCBs with more than 3 layers, add 2 business days for each additional layer

|

HDI buried

blind vias

PCB and

Rigid-Flex

PCB

|

2-3L

|

7

|

10-12

|

|

4-5L

|

8

|

12-15

|

|

6L

|

12

|

16-20

|

|

8L

|

15

|

20-25

|

|

10-20L

|

18

|

25-30

|

|

SMT: Add an additional 1-2 business days to the above delivery time

|

|

RFQ:2 working hours CS:24 working hours

|

|

EQ:4 working hours Production capacity: 80000m/month

|

Instant Quote for Flexible PCB and Flex PCB Assembly

Kaboer produces in its own factory and is controlled by a team of experts with 15 years of experience to ensure that every product is 100% qualified.