Drone Circuit Board Order Custom Pcb Online Cheapest Custom Pcb Manufacturer

How Capel's Single-sided Advanced Circuits Flex Pcb Provides Reliability Solutions for UVA

1 Layer Single Sided Flex Printed Circuit Board Immersion Gold is applicated in UVA

-Capel with 15 years of professional technical experience-

Introducing our newest product, 1-layer PFC flex circuits. As a custom PCB manufacturer, we are committed to providing our customers with the highest quality products and services. With our quick-turn rigid-flex PCB, HDI PCB prototyping and printed circuit board assembly (PCBA) services, we ensure your needs are met efficiently and effectively.

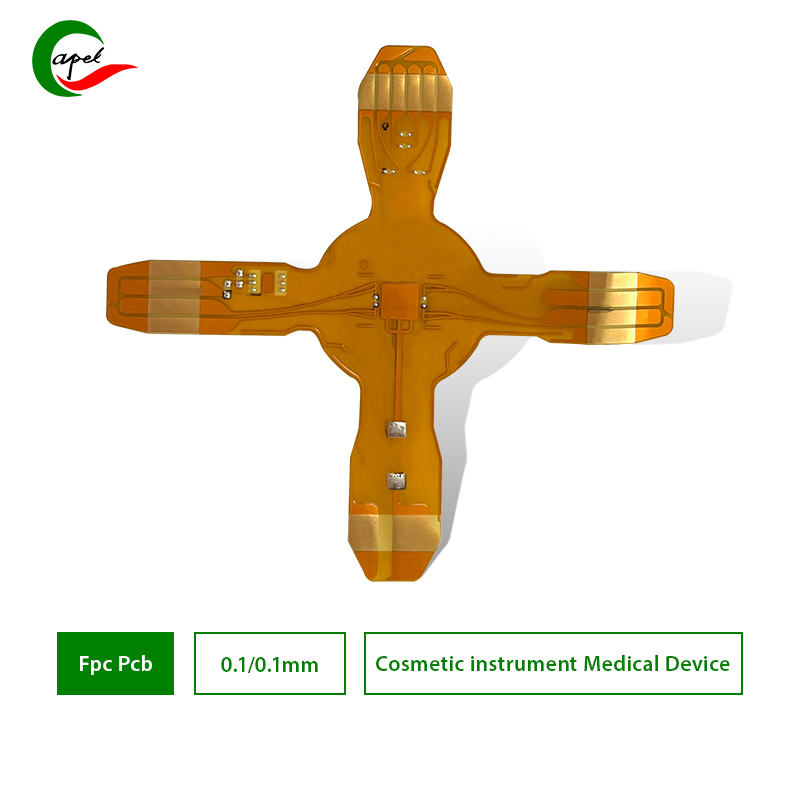

1-layer PFC flexible circuit, also known as single-layer PCB or single-sided PCB board, its line width and line spacing are designed to be 0.1/0.1mm. This ensures a precise electrical connection for seamless operation. The plate thickness is kept at 0.1mm, providing a slim and light solution for your application.

Product introduction: 1-layer single-sided flexible circuit board immersion gold

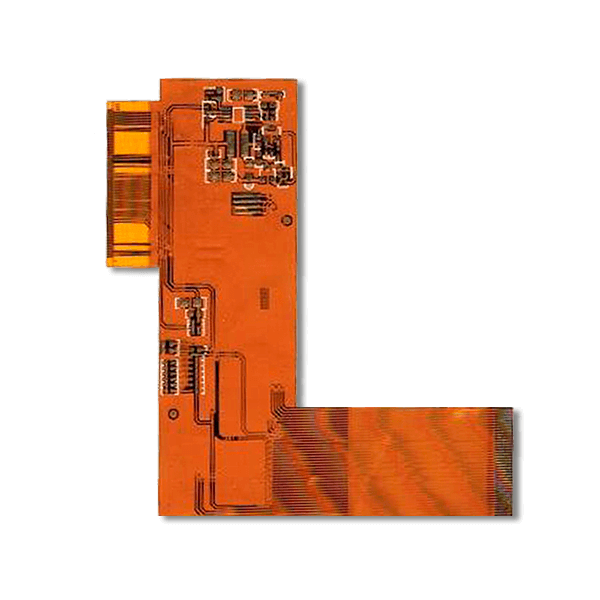

We are pleased to introduce our newest product, 1-layer single-sided flexible printed circuit board with immersion gold finish. This cutting-edge PCB is designed for Unmanned Aerial Vehicles (UAVs), also known as drones. With its advanced features and high-quality materials, this PCB is sure to revolutionize the drone industry.

As a leading provider of custom circuit boards, rapid PCB prototyping, low cost PCB prototyping and fast turnaround PCB assembly services, we understand the market's need for reliable, efficient PCBs. Our 1-layer single-sided flex PCB is a testament to our commitment to providing quality products that meet and exceed our customers' expectations.

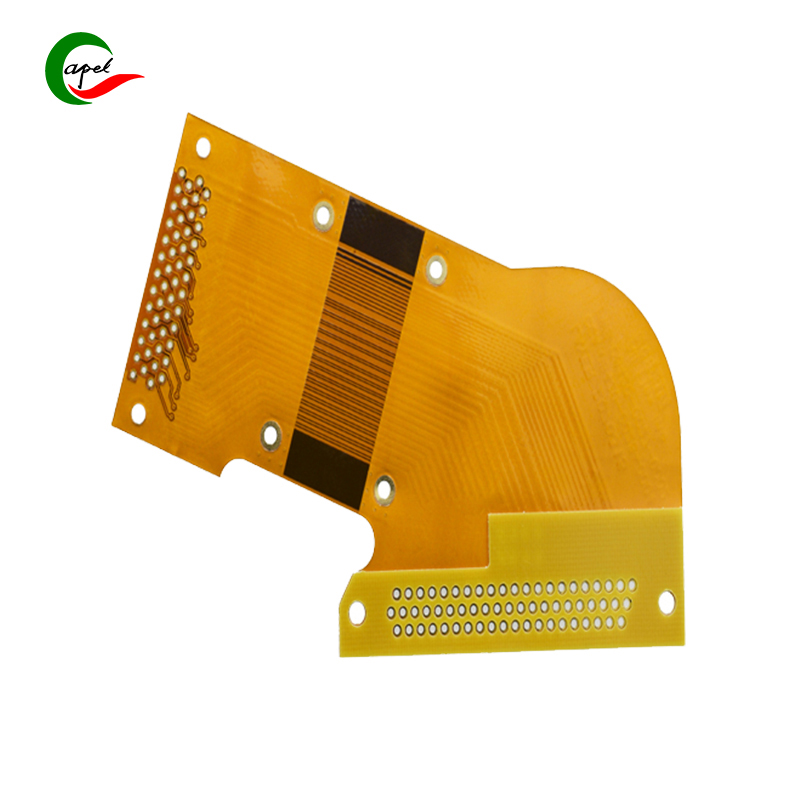

One of the key features of our 1-layer single-sided flex PCB is its line width and line spacing of 0.2/0.3mm. This ensures precise and accurate electrical connections for optimal performance of the drone. Additionally, the 0.13mm plate thickness and 18um copper thickness provide the durability and conductivity required for seamless operation.

To ensure the highest level of safety, our 1-layer single-sided flex PCBs are made of 94V0 compliant flame retardant material. This not only reduces the risk of fire, but also ensures the longevity of the PCB even in harsh environments.

The immersion gold finish provides several advantages to our 1-layer single-sided flex PCB. It enhances the conductivity and solderability of the PCB for better performance and reliability. The yellow resistance solder color further adds to the aesthetics of the PCB.

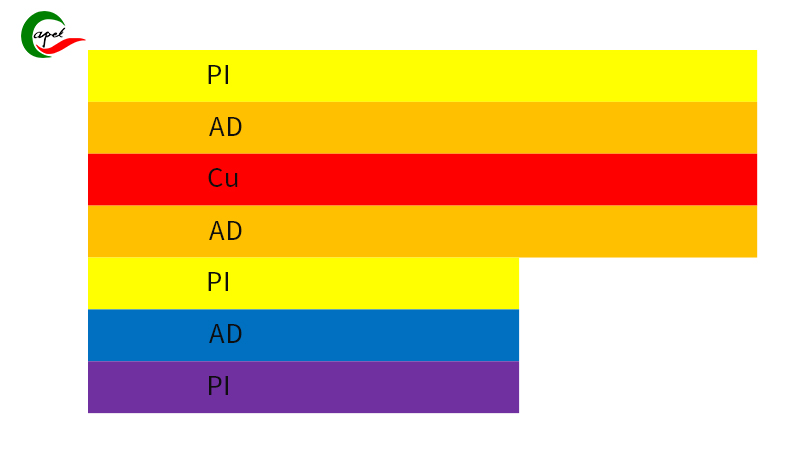

In terms of flexibility and stiffness, our 1-layer single-sided flex PCBs are made with polyimide (PI) substrates, allowing them to bend and adapt to different shapes and structures. This flexibility is critical for drone applications where PCBs need to fit in tight and tight spaces.

Our 1-layer single-sided flexible PCB is widely used in UVA equipment. Whether for aerial photography, surveillance, or even rescue operations, our PCBs are designed to meet the demanding requirements of the drone industry. Its solid construction, high performance and durability make it ideal for UVA equipment of all sizes and capabilities.

In summary, our 1-layer single-sided FPC with immersion gold finish is ideal for drone applications. With advanced features such as precise line width and spacing, flame retardant material, immersion gold surface treatment and PI substrate, this PCB provides unmatched performance and reliability. Choose our 1-layer single-sided flex PCB for your UVA devices and experience the difference in efficiency and quality.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

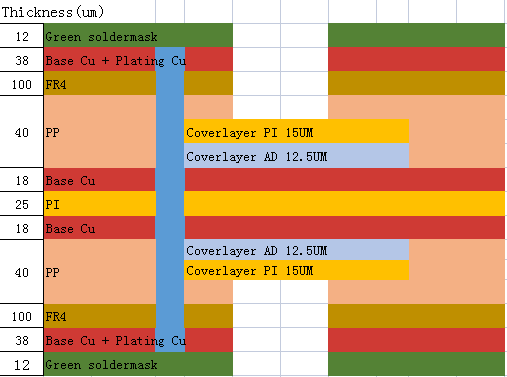

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

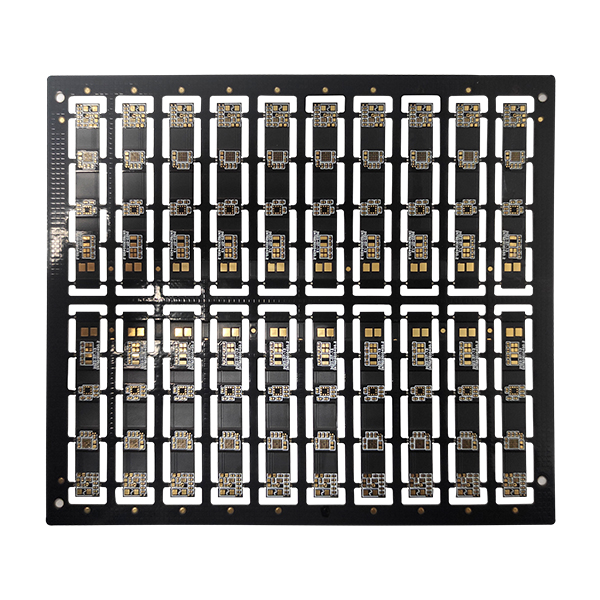

1 Layer Single Sided Flex Printed Circuit Board

4-layers Rigid-Flex PCB

8 layer HDI PCBs Stackup

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.