Double Sided Fpc Pcb Fast Turn Custom Pcb Hollow Gold Finger FR4

How Capel's Double Sided Fpc Pcb Fast Turn Custom Pcb Hollow Gold Finger FR4 Provides Reliability Solutions for B-ultrasound probe medical equipment manufacturer

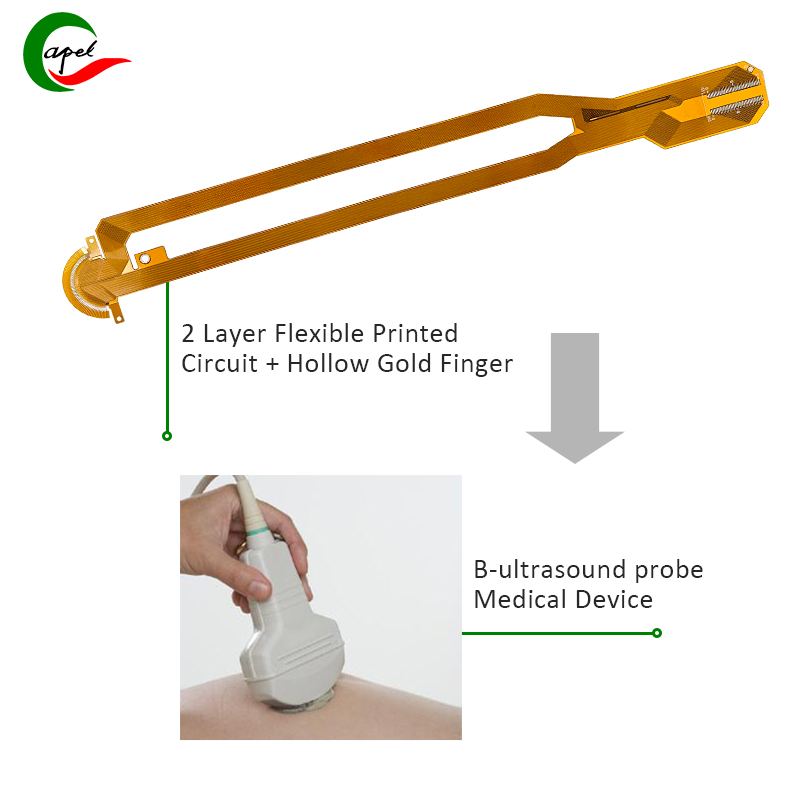

2 Layer Flexible Printed Circuit applicated in B-ultrasound probe Medical Device

-Capel with 15 years of professional technical experience-

How Capel's 2-layer flexible printed circuit provides technical support for ultrasound probe medical equipment

In the field of medical devices, innovation plays a vital role in improving patient care and treatment outcomes. The B-ultrasound probe is one such innovative technology that has revolutionized the medical industry. The device has become an important tool for medical professionals in diagnosing and monitoring a variety of conditions.

To ensure the effectiveness and reliability of ultrasound probes, manufacturers must employ cutting-edge technology and components. Among them, Capel 2-layer flexible printed circuit (FPC) stands out as a key technology providing critical support for these medical devices.

Capel 2-layer FPCs have several unique features that make them ideal for use with B-ultrasound probes. One of these features is the hollow golden finger. This specialized design element enables better signal transmission and electrical performance, ensuring accurate and high-quality imaging of the B-ultrasound probe.

Let's take a deeper look at the product features and specifications of Capel 2 Layer FPC:

Product Type: Flexible Printed Circuit

The flexibility of the Capel FPC allows greater freedom in design and allows the creation of compact, lightweight B-ultrasound probes. This flexibility also increases the overall durability and longevity of the device, making it suitable for long-term use in medical settings.

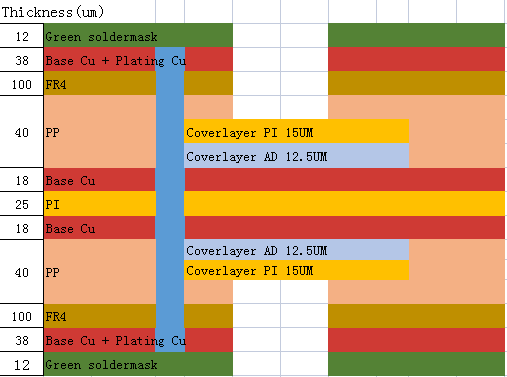

Number of layers: 2 layers

Capel FPC's 2-layer design strikes the perfect balance between cost-effectiveness and functionality. FPC has two layers and can accommodate complex circuits without compromising quality or reliability.

Line width, line spacing: 0.06/0.08mm

The precise linewidth and spacing of Capel FPCs ensures optimal signal transmission, minimizing interference and distortion. This accurate and consistent electrical performance is critical to obtaining clear and accurate ultrasound images.

Plate thickness: 0.1mm

The ultra-thin plate thickness of Capel FPC contributes to the overall compactness and light weight of the B-ultrasound probe. It can be easily integrated into equipment without adding bulk or weight.

Copper thickness: 12um

The 12um copper thickness of Capel FPC ensures excellent electrical conductivity and efficient heat dissipation. This feature is especially important for ultrasound probes as it helps prevent overheating and ensures reliable performance even during prolonged use.

Minimum aperture: 0.1mm

The small minimum aperture of Capel FPCs enables precise connections between components, reducing the risk of signal loss or electrical instability. This level of precision is critical for medical devices where reliability and accuracy are critical.

Flame retardant: 94V0

The flame retardant properties of Capel FPC make it a safe and reliable choice for the medical industry. This feature ensures that in the event of any fire-related event, the FPC will not contribute to the spread of fire, thereby minimizing the risk to patients and medical professionals.

Surface treatment: immersion gold

The immersion gold finish of Capel FPC provides excellent solderability and corrosion resistance. This treatment enhances the FPC's overall durability and longevity, making it suitable for long-term use in demanding medical environments.

Resistance welding color: yellow

The distinctive yellow color of Capel FPC indicates its resistance welding properties. This feature ensures a safe and secure connection between components, minimizing the risk of loose connections or electrical failure.

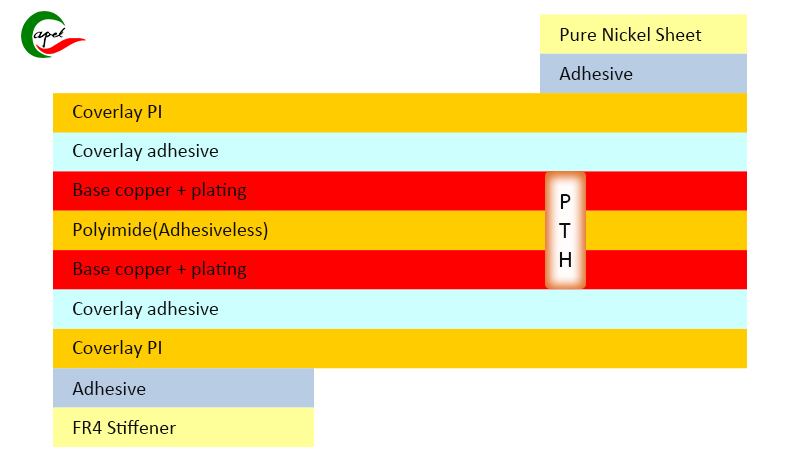

Rigidity: FR4

Capel FPC's FR4 Rigidity strikes the perfect balance between flexibility and rigidity. This stiffness allows for easy integration into the B-ultrasound probe while providing the necessary structural integrity and support.

Special craft: Hollow gold fingers

Hollow gold finger is a special process in Capel FPC manufacturing. This unique design element enhances signal transmission, reduces noise interference, and improves overall electrical performance. Hollow gold fingers play a vital role in ensuring high-quality imaging and accurate diagnosis of B-ultrasound probes.

Application: Medical Devices

Capel 2-layer FPCs are designed for medical devices. Its unique features and specifications are tailored to the requirements of ultrasound probes, making it ideal for medical device manufacturers aiming to provide reliable and accurate imaging solutions.

Application device: B-ultrasound probe

B Ultrasound probes are an important medical tool used in a variety of medical settings, including obstetrics, gynecology, and general diagnostics. Compatibility of Capel 2-layer FPCs with B-ultrasound probes ensures seamless integration and reliable performance, enhancing the overall effectiveness of these medical devices.

To sum up, Capel 2-layer flexible circuit board and its hollow gold finger technology play a vital role in providing technical support for B-ultrasound probes. Capel FPC's unique features and specifications, combined with its compatibility with medical devices, make it an excellent choice for manufacturers looking to enhance the overall performance and reliability of B ultrasound probes. With its superior signal transmission capabilities and superior electrical performance, Capel FPCs ensure accurate and high-quality imaging that ultimately benefits medical professionals and patients.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

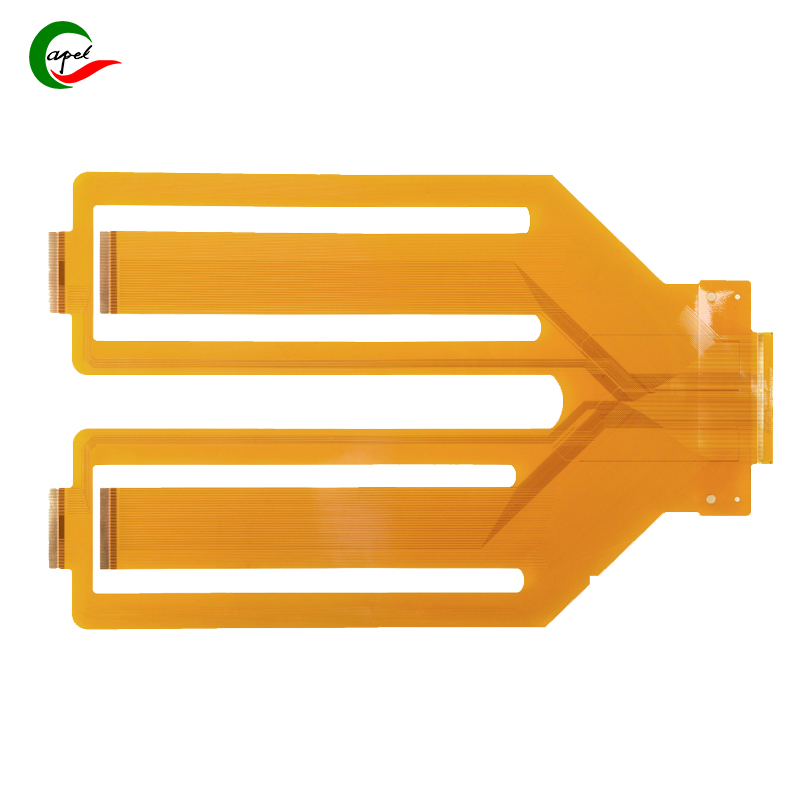

2 Layers Double-sided Fpc Pcb

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

.jpg)