Double-Side PCB Multi-Layer Rigid-Flex PCBs Manufacturing for IOT

Specification

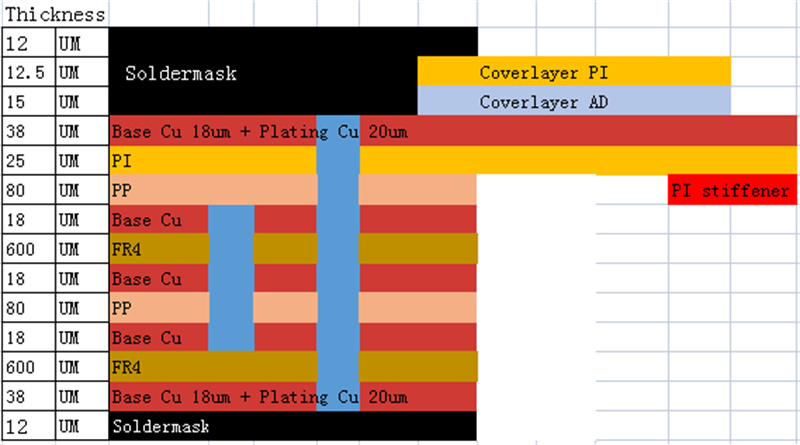

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi- layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-16 layers FPC 2-16 layers Rigid-FlexPCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Doulbe layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plat ing/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

We do Rigid-Flexible Circuit Boards with 15 years' experience with our professionalism

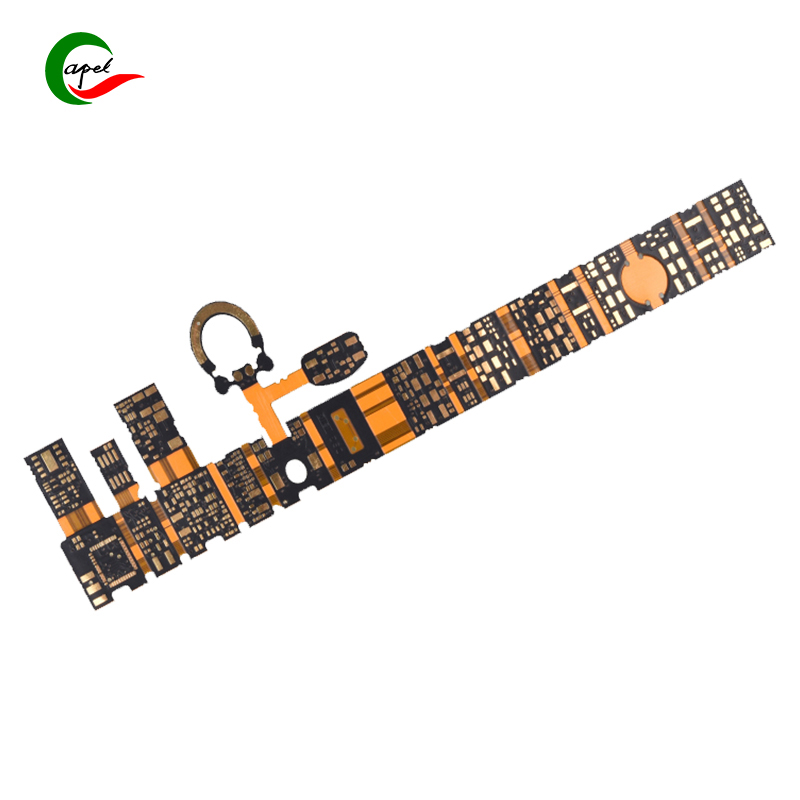

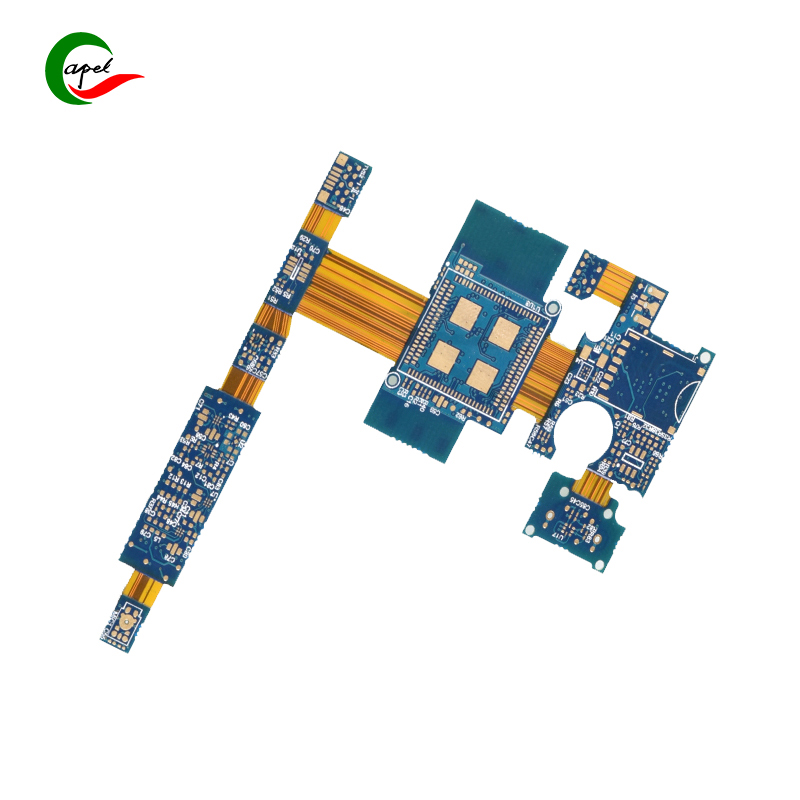

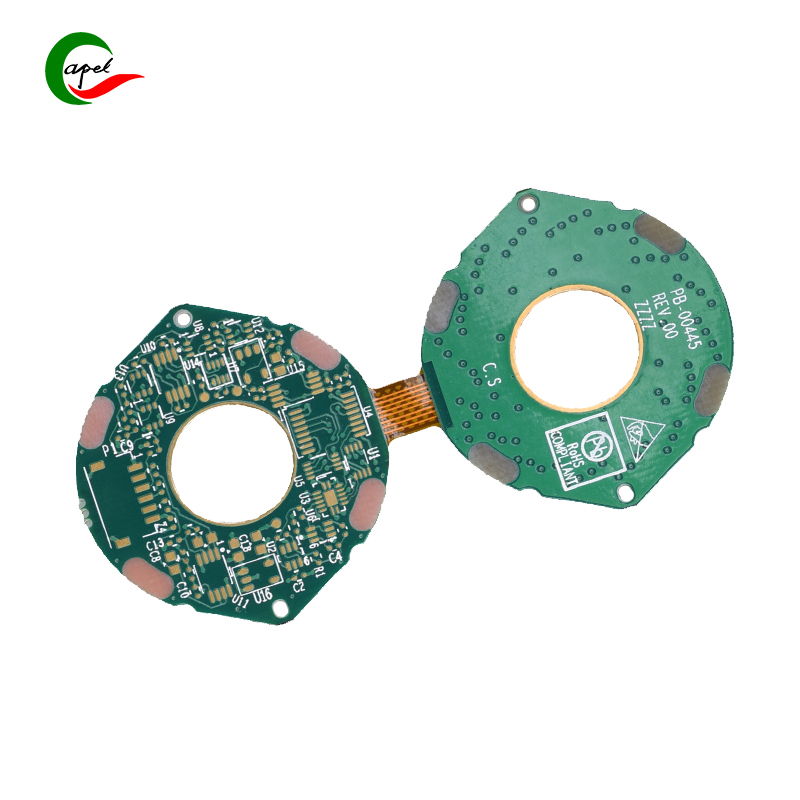

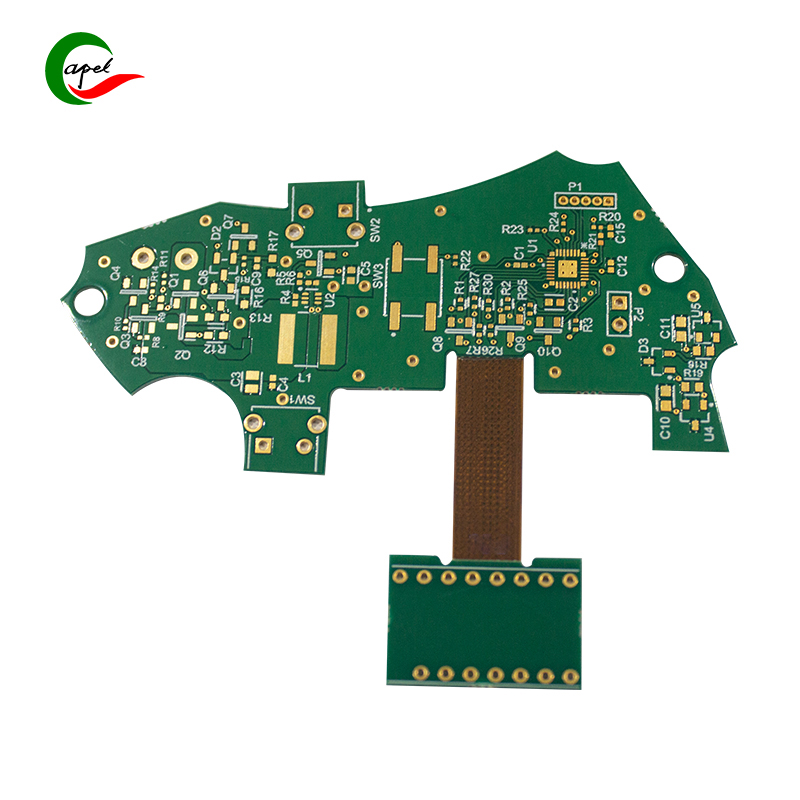

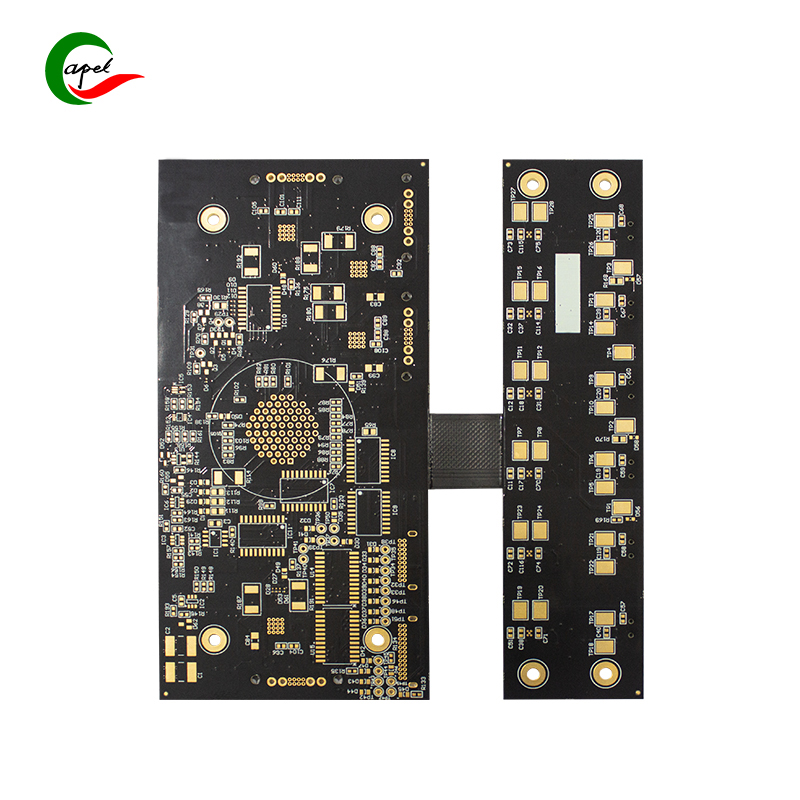

5 layer Flex-Rigid Boards

8 layer Rigid-Flex PCBs

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Our Rigid-Flexible Circuit Boards Service

. Provide technical support Pre-sales and after-sales;

. Custom up to 40 layers, 1-2days Quick turn reliable prototyping, Component procurement,SMT Assembly;

. Caters to both Medical Device, Industrial Control, Automotive, Aviation, Consumer Electronics, IOT, UAV, Communications etc..

. Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

how Multi-layer Rigid-Flex PCBs applicated in IoT Device

1. Space optimization: IoT devices are usually designed to be compact and portable. Multilayer Rigid-Flex PCB enables efficient space utilization by combining rigid and flex layers in one board. This allows components and circuits to be placed in different planes, optimizing the use of available space.

2. Connecting Multiple Components: IoT devices typically consist of multiple sensors, actuators, microcontrollers, communication modules, and power management circuits. A multilayer rigid-flex PCB provides the connectivity needed to connect these components, allowing seamless data transfer and control within the device.

3. Flexibility in shape and form factor: IoT devices are often designed to be flexible or curved to fit a specific application or form factor. Multilayer rigid-flex PCBs can be manufactured using flexible materials that allow bending and shaping, enabling the integration of electronics into curved or irregularly shaped devices.

4. Reliability and durability: IoT devices are often deployed in harsh environments, exposed to vibrations, temperature fluctuations, and moisture. Compared with traditional rigid or flex PCB, multilayer rigid-flex PCB has higher durability and reliability. The combination of rigid and flexible layers provides mechanical stability and reduces the risk of interconnect failure.

5. High-density interconnect: IoT devices often require high-density interconnects to accommodate various components and functions.

Multilayer Rigid-Flex PCBs provide multilayer interconnections, allowing for increased circuit density and more complex designs.

6. Miniaturization: IoT devices continue to become smaller and more portable. Multilayer rigid-flex PCBs enable the miniaturization of electronic components and circuits, allowing the development of compact IoT devices that can be easily integrated into various applications.

7. Cost efficiency: Although the initial manufacturing cost of multilayer rigid-flex PCBs may be higher compared to traditional PCBs, they can save costs in the long run. Integrating multiple components on a single board reduces the need for additional wiring and connectors, simplifies the assembly process and reduces overall production costs.

the trend of Rigid-Flex PCBs in IOT FAQ

Q1: Why are rigid-flex PCBs becoming popular in IoT devices?

A1: Rigid-flex PCBs are gaining popularity in IoT devices due to their ability to accommodate complex and compact designs.

They offer a more efficient use of space, higher reliability, and improved signal integrity compared to traditional PCBs.

This makes them ideal for the miniaturization and integration required in IoT devices.

Q2: What are the advantages of using rigid-flex PCBs in IoT devices?

A2: Some key advantages include:

- Space-saving: Rigid-flex PCBs allow for 3D designs and eliminate the need for connectors and additional wiring, thus saving space.

- Improved reliability: The combination of rigid and flexible materials increases the durability and reduces points of failure, improving the overall reliability of IoT devices.

- Enhanced signal integrity: Rigid-flex PCBs minimize electrical noise, signal loss, and impedance mismatch, ensuring reliable data transmission.

- Cost-effective: Although initially more expensive to manufacture, in the long term, rigid-flex PCBs can reduce assembly and maintenance costs by eliminating additional connectors and simplifying the assembly process.

Q3: In which IoT applications are rigid-flex PCBs commonly used?

A3: Rigid-flex PCBs find applications in various IoT devices, including wearable devices, consumer electronics, healthcare monitoring devices, automotive electronics, industrial automation, and smart home systems. They offer flexibility, durability, and space-saving advantages required in these application areas.

Q4: How can I ensure the reliability of rigid-flex PCBs in IoT devices?

A4: To ensure reliability, it is important to work with experienced PCB manufacturers who specialize in rigid-flex PCBs.

They can provide design guidance, proper material selection, and manufacturing expertise to ensure the durability and functionality of the PCBs in IoT devices. Additionally, thorough testing and validation of the PCBs should be conducted during the development process.

Q5: Are there any specific design guidelines to consider when using rigid-flex PCBs in IoT devices?

A5: Yes, designing with rigid-flex PCBs requires careful consideration. Important design guidelines include incorporating proper bend radiuses, avoiding sharp corners, and optimizing component placement to minimize stress on the flex regions. It is essential to consult with PCB manufacturers and follow their guidelines to ensure a successful design.

Q6: Are there any standards or certifications that rigid-flex PCBs need to meet for IoT applications?

A6: Rigid-flex PCBs may need to comply with various industry standards and certifications based on the specific application and regulations.

Some common standards include IPC-2223 and IPC-6013 for PCB design and manufacturing, as well as standards related to electrical safety and electromagnetic compatibility (EMC) for IoT devices.

Q7: What does the future hold for rigid-flex PCBs in IoT devices?

A7: The future looks promising for rigid-flex PCBs in IoT devices. With the increasing demand for compact and reliable IoT devices, and advancements in manufacturing techniques, rigid-flex PCBs are expected to become more prevalent. The development of smaller, lighter, and more flexible components will further drive the adoption of rigid-flex PCBs in the IoT industry.