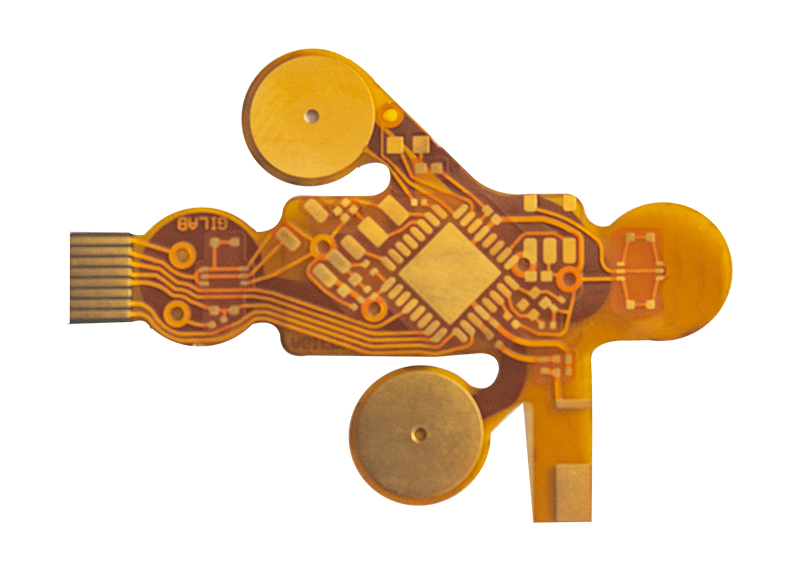

Infrared Analyzer Medical Device

| Technical requirements | ||||||

| Product type | Double Sided Flex Circuit Pcb Board | |||||

| Number of layer | 2 Layers | |||||

| Line width and line spacing | 0.12/0.1mm | |||||

| Board thickness | 0.15mm | |||||

| Copper Thickness | 18um | |||||

| Minimum Aperture | 0.15mm | |||||

| Flame Retardant | 94V0 | |||||

| Surface Treatment | Immersion Gold | |||||

| Solder Mask Color | Yellow | |||||

| Stiffness | PI、FR4 | |||||

| Application | Medical Device | |||||

| Application Device | Infrared Analyzer | |||||

Case Study: Infrared analyzer medical device 2-layer flexible PCB board

Introduce:

2-layer flexible PCB boards for infrared analyzer medical devices are critical components to the overall functionality and performance of the device. This case analysis will focus on the technical aspects of the product, including line width and spacing, board thickness, copper thickness, minimum aperture, flame retardant grade, surface treatment, solder mask color, stiffness, etc. It will also highlight its target applications and devices.

Product type:

2-layer flexible PCB board This product is a 2-layer flexible PCB board. These panels are designed to be lightweight and flexible, making them ideal for applications where panels need to conform to a specific shape or fit into tight spaces.

Technical specifications:

Line Width and Space: PCB board line width and space dimensions are critical to ensuring proper signal integrity and reliability. In this example, the line width is 0.12mm and the line spacing is 0.1mm, ensuring the accuracy of signal transmission.

Board thickness: 0.15mm board thickness determines the overall flexibility and durability of the PCB. This consideration is important to ensure that the board can withstand the stresses associated with bending or bending without affecting its functionality.

Copper Thickness: 18um copper thickness provides the conductivity required to transmit signals across the PCB. This thickness is carefully chosen to balance conductivity with overall board flexibility.

Minimum hole diameter: The minimum hole diameter 0.15mm refers to the minimum hole size that can be drilled on the PCB. This precision is critical to accommodate components and ensure proper connections.

Flame retardancy: The flame retardant grade reaches 94V0, indicating that the PCB material has high fire resistance and is self-extinguishing. This is critical for safety considerations, especially in medical device applications.

Surface treatment: Immersed gold surface treatment has excellent conductivity and corrosion resistance. It guarantees reliable connection and long-term stability of the PCB.

Solder Mask Colors: The yellow color of resistance welding indicates the specific material or coating used in the welding process. The yellow color may be chosen for aesthetic reasons or to distinguish a specific area on the PCB.

Stiffness: PCBs are designed with flexibility in mind and a combination of materials can be used to achieve the required stiffness. In this case, materials such as PI (Polyimide) and FR4 (Flame Retardant 4) can be used to provide the necessary balance between flexibility and rigidity.

Applications and Devices: 2 layer flexible PCB board specially designed for infrared analyzer medical equipment. These devices utilize infrared technology to analyze and measure various parameters in medical samples. The flexible PCB makes the device compact, lightweight and ergonomically designed for both portable and stationary medical applications.

Post time: Sep-07-2023

Back