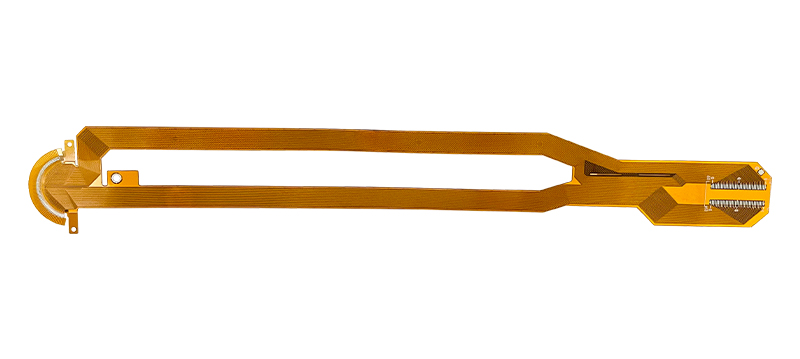

B-ultrasound probe Medical Device

| Technical requirements | ||||||

| Product type | Flex Board Pcb | |||||

| Number of layer | 2 Layers | |||||

| Line width and line spacing |

0.06/0.08mm | |||||

| Board thickness | 0.1mm | |||||

| Copper Thickness | 12um | |||||

| Minimum Aperture | 0.1mm | |||||

| Flame Retardant | 94V0 | |||||

| Surface Treatment | Immersion Gold | |||||

| Resistance Welding Color | Yellow | |||||

| Stiffness | FR4 | |||||

| Special Process | Hollow Gold Finger | |||||

| Application Industry | Medical Device | |||||

| Application Device | B-ultrasound probe | |||||

Case Analysis--Capel with 15 years of professional technical experience

Flexible circuit boards provide safe and reliable solutions for the medical industry.

How do Capel's high-precision 2-layer flexible circuit boards provide innovative technical support for medical equipment such as B-ultrasound probes?

In today's fast-paced world, technology plays a vital role in improving various industries, and the medical field is no exception. Among many advanced medical devices, B-ultrasound probes have always attracted people's attention. The device allows medical professionals to view real-time images of internal organs, making it an indispensable tool for diagnosing and monitoring a variety of medical conditions.

One of the key components of a B-ultrasound probe is a 2-layer flexible printed circuit (FPC). FPC, also known as double-sided PCB (Printed Circuit Board), is a thin and flexible board that serves as a platform for connecting electronic components in a compact and efficient manner. The FPC used in the ultrasound probe is specially designed to meet the demanding requirements of the medical field, ensuring reliable and high-performance operation.

Let's take a closer look at the specifications and characteristics of the 2-layer FPC used in the B-ultrasound probe. The board is 0.1 mm thick, allowing it to be easily integrated into the probe's compact design. The line width and line spacing are 0.06/0.08mm, ensuring fast and efficient signal transmission. The 12um copper thickness provides excellent electrical conductivity while maintaining the overall flexibility of the board.

To ensure the highest level of safety, the 2-layer FPC used in the ultrasound probe is manufactured with a flame-retardant material called 94V0. This material is highly fire resistant, minimizing the risk of accidents and damage. In addition, the surface treatment of FPC adopts immersion gold, which not only enhances the conductivity of the board, but also has excellent corrosion resistance.

One of the notable features of the 2-layer FPC used in the B-ultrasound probe is its special process called hollow gold finger. This process involves plating the FPC's connectors with a thin layer of gold to enhance their durability and ensure a reliable connection. The resistance welding color of FPC is yellow, which not only adds visual appeal, but also facilitates quick identification during manufacturing and assembly.

The 2-layer FPC is applied in the B-ultrasound probe and is an important part to ensure accurate and reliable imaging. Its flexibility allows it to conform to the curved shape of the probe for easy handling during inspection. The high-performance characteristics of FPC, such as fast signal transmission and excellent electrical conductivity, contribute to the overall efficiency and accuracy of B-ultrasound probes.

In summary, 2-layer flexible printed circuits have revolutionized the medical field, especially in the field of ultrasound probes. Its compact design, excellent electrical conductivity, and flexibility make it ideal for this advanced medical device. With its many features and specifications tailored to meet the stringent requirements of the medical field, 2-layer FPCs play a vital role in helping medical professionals provide accurate diagnoses and deliver necessary medical care.

Post time: Sep-04-2023

Back