How 8 Layer Rigid Flex Board Solutions To Improve The Performance Of VR Glasses

| Technical requirements | |

| Product type | PCB Rigid Flex |

| Number of layer | 8 Layers |

| Line width and line spacing |

0.1mm/0.1mm |

| Board thickness | 1.2mm±10% |

| Copper Hole Thickness | 35um |

| Minimum Aperture | 0.15MM |

| Surface Trestment Retardant | 94v0 |

| Surface Treatment | ENIG 2-3uin |

| Warpage | ≦0.5% |

| Tolerance Accuracy | ±0.1MM |

| Layers Stackup | 2+4+2 |

| Application Industry | Smart Wearable Industry |

| Application Device | VR Smart Glasses |

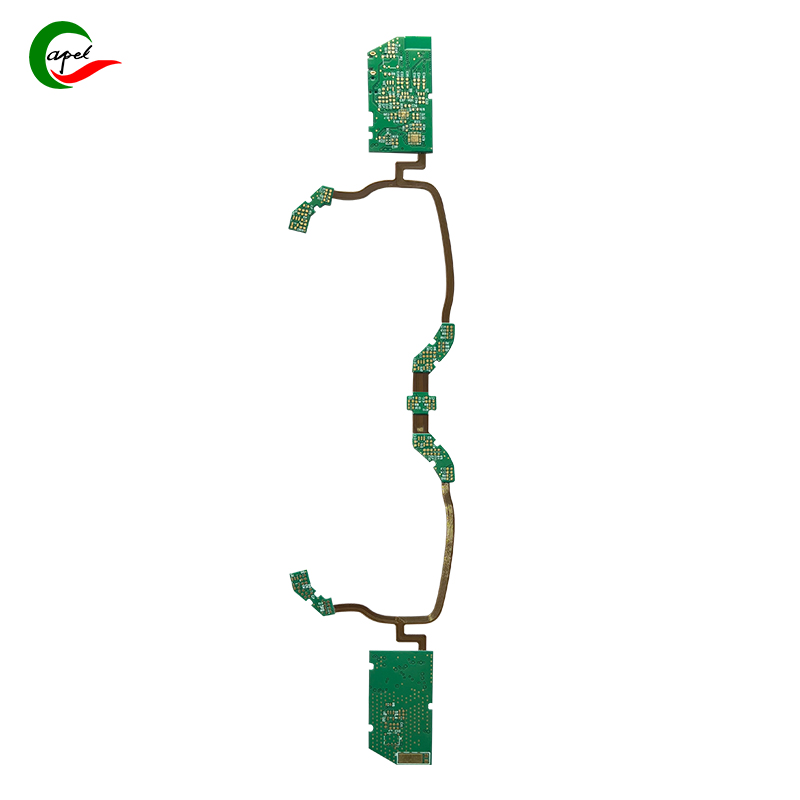

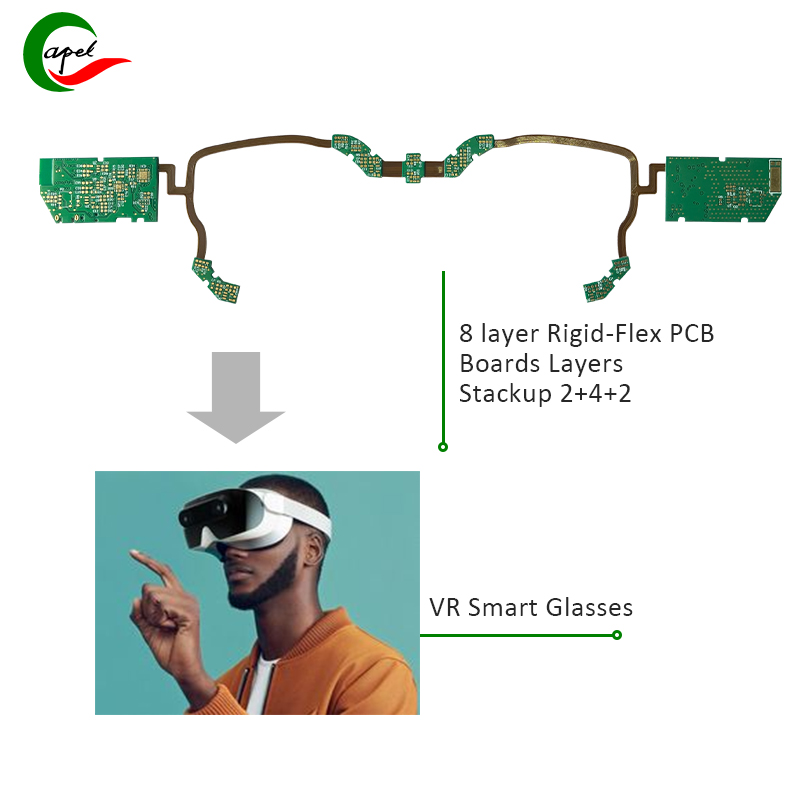

8 Layers Rigid Flex PCB Prototype

VR Smart Glasses

Are you looking for reliable and high-performance solutions of 8-layer rigid flex board for your VR smart glasses in the smart wearable industry? Our multi-layer rigid flex pcb prototype technologies are your best choice, specially designed for smart wearable industry.

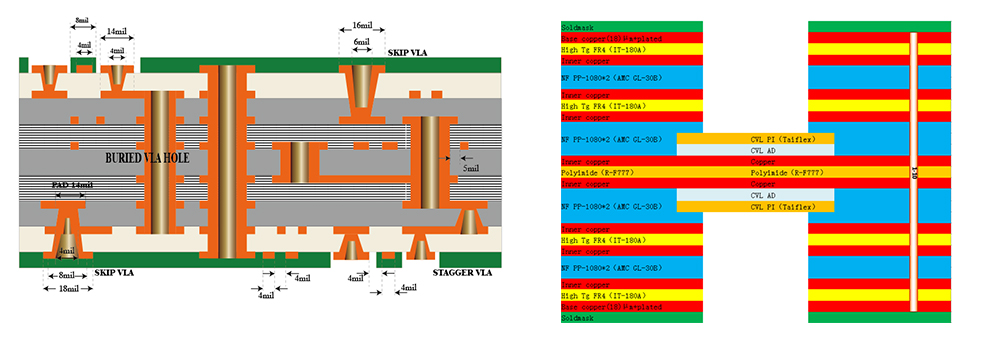

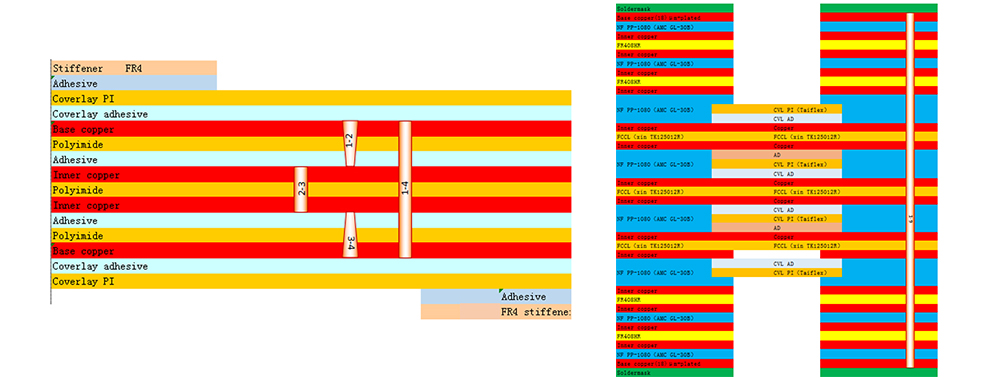

Introducing our cutting-edge 8-layer rigid-flex board solution designed to revolutionize the performance of VR glasses. As demand for high-quality VR experiences continues to soar, our rigid-flex boards are engineered to meet the stringent requirements of VR smart glasses, ensuring unparalleled performance and reliability. Our rigid-flex boards are stacked in 2+4+2 layers with a board thickness of 1.2mm±10% and a minimum aperture of 0.15mm. They are carefully crafted to provide excellent results. Whether it is 0.1mm/0.1mm line width and spacing, 35um copper hole thickness, or ENIG 2-3uin surface treatment, our boards have mature craftsmanship and technical precision, setting a new standard for VR glasses performance.

The 8-layer rigid-flex board solution is customized to enhance the performance of VR glasses. Featuring 8 carefully engineered layers, these boards offer unparalleled flexibility and reliability, making them ideal for demanding applications such as VR smart glasses. The 2+4+2 layer stacking ensures optimal signal integrity and power distribution, while the 1.2mm±10% board thickness strikes the perfect balance between durability and flexibility. This meticulous design, combined with a minimum aperture of 0.15mm, ensures our rigid-flex boards deliver superior performance even in the most demanding VR environments.

In terms of technical specifications, our 8-layer rigid-flex board solution stands out from the competition. With 0.1mm/0.1mm line widths and spacing, these boards provide precise signal routing and superior electrical performance, which is critical for seamless operation of VR glasses. The 35um copper hole thickness further enhances the circuit board’s conductivity and reliability, ensuring they can meet the stringent requirements of VR applications. Additionally, surface treatment with ENIG 2-3uin provides excellent corrosion resistance and solderability, making our rigid-flex boards perfect for long-lasting VR glasses solutions.

Our 8-layer rigid-flex board solution uses mature processes and a relentless pursuit of precision to provide unparalleled tolerance accuracy. With a tolerance accuracy of ±0.1mm, these boards are designed to meet the most stringent requirements of VR glasses, ensuring seamless integration and reliable performance. In addition, the board has a warpage of ≤0.5%, ensuring consistent and stable operation even in dynamic VR environments. This level of precision and reliability sets our rigid-flex boards apart, making them the first choice for enhancing the performance of VR glasses.

In summary, our 8-layer rigid-flex board solution represents a leap forward in improving the performance of VR glasses. With rigorous engineering design, precise technology and mature craftsmanship, these boards are designed to meet the stringent requirements of VR smart glasses. From 2+4+2 layer stacking to 0.1mm/0.1mm line width and spacing, every aspect of our rigid-flex boards is optimized to deliver superior performance and reliability. Whether it is copper hole thickness, surface treatment or tolerance accuracy, our circuit boards set new standards for VR glasses solutions. If you're looking to improve the performance of your VR glasses, our 8-layer rigid-flex board solution is the perfect choice.

WHY CHOOSE OUR CAPEL

Shenzhen Capel Technology Co., Ltd. has been specializing in the production of high-end, high-precision flexible circuit boards since 2009.

We have 15 years of professional and technical experience and have mature, excellent, and advanced manufacturing capabilities.

We are able to provide customized 1-30 layer flexible circuit boards,2-32 layer rigid-flex PCBs, and 1-60 layers rigid PCBs to customers in the Automotive Industry.

Support Custom 1-30 Layer FPC Flexible PCB,2-32 Layer Rigid-Flex Circuit Boards,1-60 Layer Rigid PCB, High-Precision HDI Boards, Reliable Quick Turn PCB Prototyping, Fast Turn SMT PCB Assembly

Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC Flexible PCB 2-32 layers Rigid-FlexPCB1-60 layers Rigid PCBHDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layer FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness | 27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size | ±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance | ±10% |

| Tolerance of NPTH Size | ±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard | GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

| Immersion Gold | AU 0.025-0.075UM /NI1-4UM | Electro nickel gold | AU 0.025-25.4UM / NI 1-25.4UM |

| Certifications | UL and ROHS ISO 14001:2015 ISO 9001:2015 IATF16949:2016 |

Patents | model patents invention patents |

8 layer HDI Flexible PCBs for Medical 10 layer Rigid-Flex Circuit Boards for Aerospace

4 layer Flex PCB Circuits for Industry Control 16 layer Rigid Flexible PCBs for Automotive

We have the latest and most advanced production equipment and technology, including high-precision photolithography machines, etching machines, assembly equipment, etc. These

equipment ensure the precision, efficiency, and stability of the production process, thereby providing customers with high-quality products. quality product. High-quality flexible circuit board products.

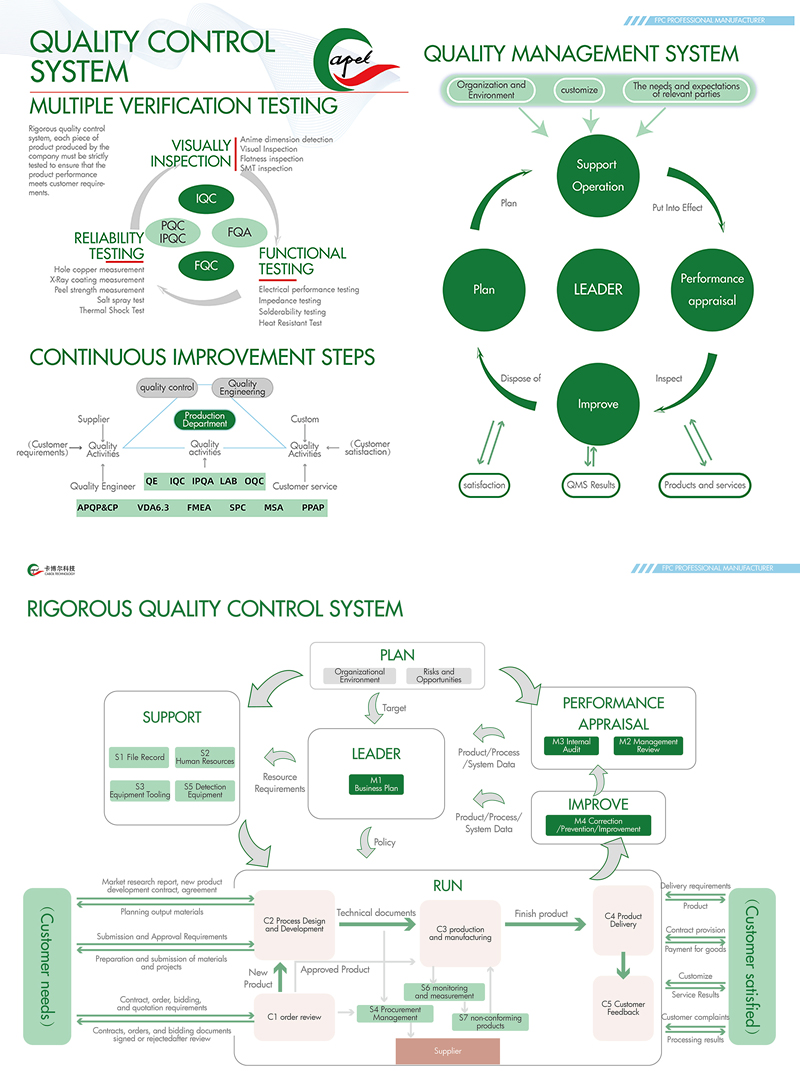

Our company puts quality control first and implements a series of strict quality control measures throughout the entire production process. Every step from the selection and procurement

of raw materials to production and packaging is comprehensively inspected and tested to ensure that every flexible circuit board product meets the highest standards.

Efficient production management:

We have an efficient production management system to optimize the production process, improve production efficiency and reduce costs. With rich production experience, we can quickly respond to customer needs and ensure timely delivery.

We are customer-centric and provide perfect after-sales service. Whether it is solving problems during product use or providing technical support and repair services, we can respond in a timely manner and provide solutions. By using these phrases, you can effectively demonstrate the company's strength and advantages in the flexible circuit board production process, thereby gaining the trust and recognition of customers.

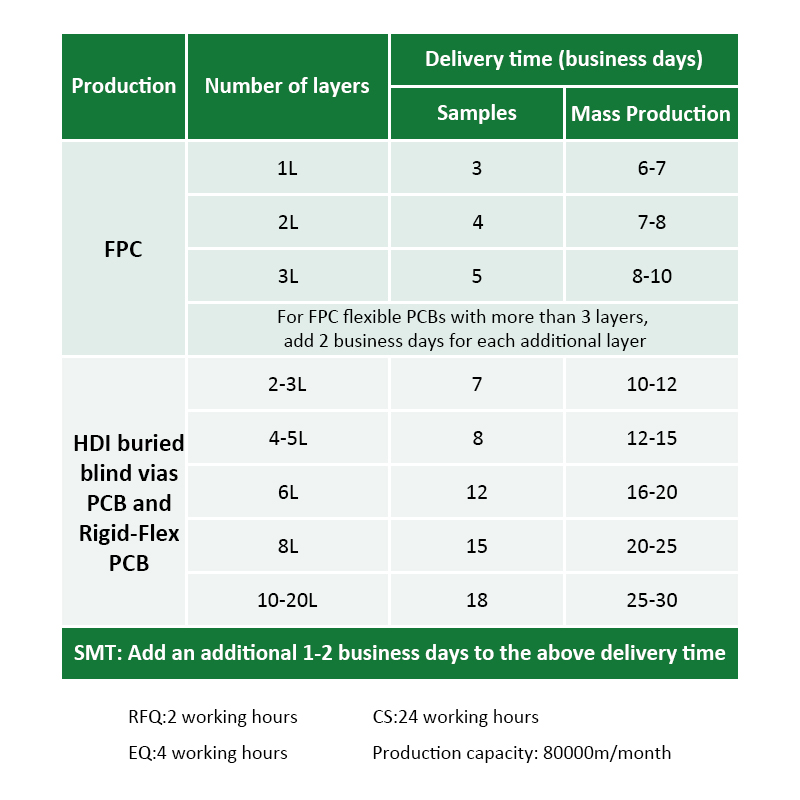

We can provide customers with high-quality rapid prototyping, reliable rapid mass production, and fast delivery to help their projects enter the market quickly and smoothly and gain competitive advantages.

Strong supply chain management:

We have established long-term cooperative relationships with a number of high-quality suppliers to ensure timely access to high-quality raw materials. At the same time, we have an efficient supply chain management team that can fully control the supply status of raw materials, ensure that materials are in place on time, and support rapid production and delivery.

Flexible production planning:

We adopt an advanced production planning system that can quickly adjust and schedule according to customer needs. Whether it is prototype production or large-scale production, we can flexibly allocate resources to complete production in a short time and ensure on-time delivery.

Efficient process flow:

We have an efficient manufacturing process and strictly plan and control the entire process from order receipt to product shipment. By optimizing the production process, improving production efficiency, and implementing quality control measures, we can quickly manufacture and deliver products to ensure the smooth start of our customers' projects.

Quick response:

We attach great importance to customer needs and are able to respond quickly and adjust production and scheduling accordingly. Whether it's an urgent order or an unexpected situation, we can make decisions quickly and take appropriate measures to ensure timely delivery.

Reliable logistics management:

We cooperate with a number of professional logistics companies to ensure that goods are delivered to customers safely and timely. We have a complete logistics management process and warehousing system that can accurately track transportation status and ensure on-time delivery.

Post time: Mar-22-2024

Back