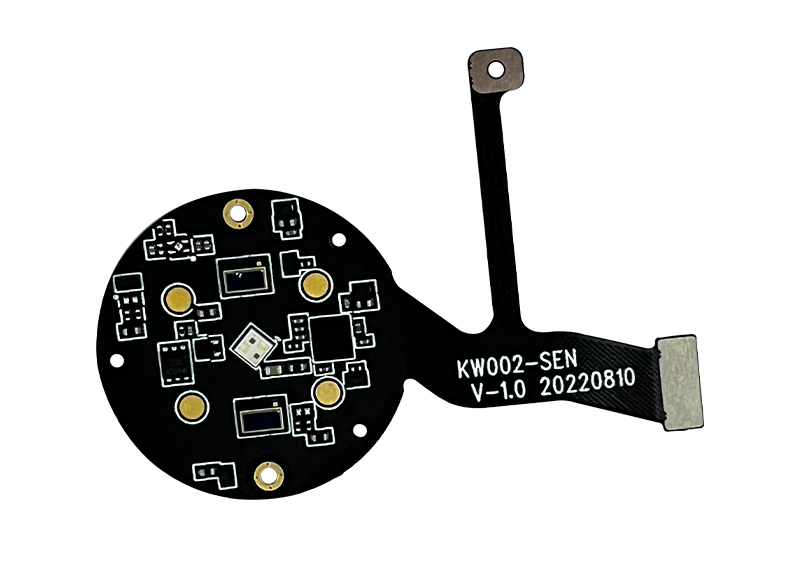

4 Layers Flexible PCB Prototype for Medical Blood Pressure Device-Case

| Technical requirements | ||||||

| Product type | Flex Circuit Board | |||||

| Number of layer | 4 Layers / Multilayer Flexible Pcb | |||||

| Line width and line spacing | 0.12/0.15mm | |||||

| Board thickness | 0.2mm | |||||

| Copper Thickness | 35um | |||||

| Minimum Aperture | 0.2mm | |||||

| Flame Retardant | 94V0 | |||||

| Surface Treatment | Immersion Gold | |||||

| Solder Mask Color | Black | |||||

| Stiffness | Steel Sheet | |||||

| Application | Medical Device | |||||

| Application Device | Blood Pressure | |||||

Case Study

Capel's Advanced Circuits Flex PCB is a 4-layer flexible printed circuit board (PCB) specially designed for medical equipment.It is mainly used in blood pressure equipment.

This product incorporates a number of technological innovations to enhance its performance and functionality in the medical device industry.

Number of Layers:

The 4-layer design of the PCB indicates a higher level of complexity and functionality. By merging multiple layers, PCBs can accommodate denser circuitry, allowing for better signal transmission and reduced crosstalk. This innovative feature ensures the accuracy and reliability of blood pressure measurements.

Line width and line spacing:

With line widths and line spacing of 0.12 mm and 0.15 mm respectively, Capel's flexible PCB demonstrates impressive miniaturization capabilities. Narrower traces and spacing enable complex circuits to be built in compact spaces, allowing medical devices to become smaller and more portable.

Board thickness:

The ultra-thin plate thickness of 0.2mm is another technical innovation of Capel's expertise. This slim profile allows flexible PCBs to be easily integrated into the design of small medical devices without compromising rigidity or durability.

Copper thickness:

35μm copper thickness ensures good conductivity and sufficient current carrying capacity. With this parameter in place, Capel's flexible PCB can efficiently transmit and distribute the electrical signals required for blood pressure measurement. It also reduces power loss and heat generation, helping to improve the overall efficiency of medical equipment.

Minimum aperture:

The minimum aperture size is 0.2mm, indicating the high precision of the design and manufacturing process. This technological innovation enables more precise circuit connections, minimizing the risk of signal interference or failure.

Flame retardant:

94V0 flame retardant grade ensures that the flexible PCB meets the strict safety standards of the medical industry. This feature is critical because it prevents PCBs from igniting or spreading fires, protecting users and medical equipment from potential hazards.

Surface Treatment:

Immersed gold surface treatment enhances conductivity and protects copper traces from corrosion. This technological innovation extends the service life of flexible PCBs and ensures the stability of electrical connections, even in harsh medical environments. Solder Mask Color:

The use of black resistance soldering color not only provides aesthetic appeal to the product but also serves as a visual indicator to differentiate the flexible PCB during assembly. This color coding simplifies the manufacturing process and eliminates the possibility of errors in component placement and soldering.

In order to further improve the industry and equipment, Capel considers the following technical improvements:

Enhanced flexibility:

As medical devices become more wear-resistant and comfortable, increasing the flexibility of flexible PCBs can enable seamless integration with these devices. By leveraging innovative materials and manufacturing techniques, Capel can increase the bending capabilities of flexible PCBs without compromising their performance or reliability.

Thinner circuit board design:

In addition to slim circuit board thickness, further reducing the thickness of flexible PCBs can provide additional advantages in terms of weight reduction and increased flexibility. This advancement will enable the development of smaller, more comfortable medical devices for patients.

Integration of advanced technologies:

Capel can support the development of smart medical devices by integrating advanced technologies such as wireless connectivity, sensors and data processing capabilities into flexible PCBs. This technological innovation will enable real-time data monitoring, improve patient experience and enhance diagnostic capabilities.

Post time: Sep-09-2023

Back