| Technical requirements | ||||||

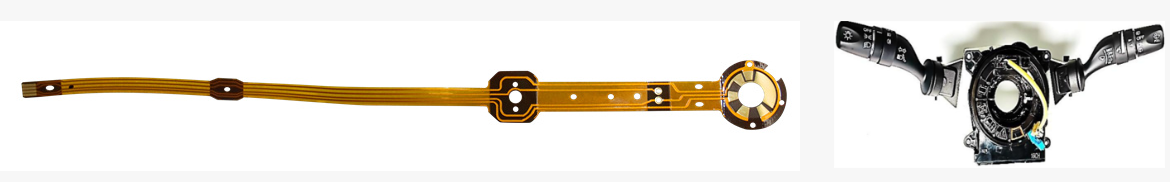

| Product type | Rigid Flex Printed Circuit Board | |||||

| Number of layer | 2 Layers | |||||

|

Line width and line spacing |

0.15MM/0.1MM | |||||

| Plate thickness | FPC=0.15MM T=1.6MM | |||||

| Copper Thickness | 1OZ | |||||

| Film Thickness | 50UM | |||||

| Surface Treatment | ENIG 2-3Uin | |||||

| Tolerance Requirements | 0.1MM | |||||

| Material | Shengyi TG170 copper clad laminate | |||||

| Characteristic | High adhesion, high reliability | |||||

| Functional testing | AOI/four-wire/continuity/copper slices | |||||

| Application Vehicle | GAC Motor | |||||

| Application | Car Combination Switch Lever | |||||

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..