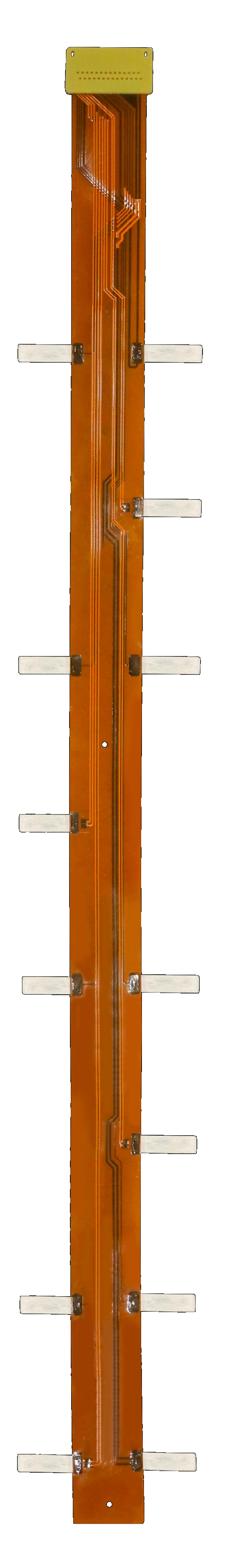

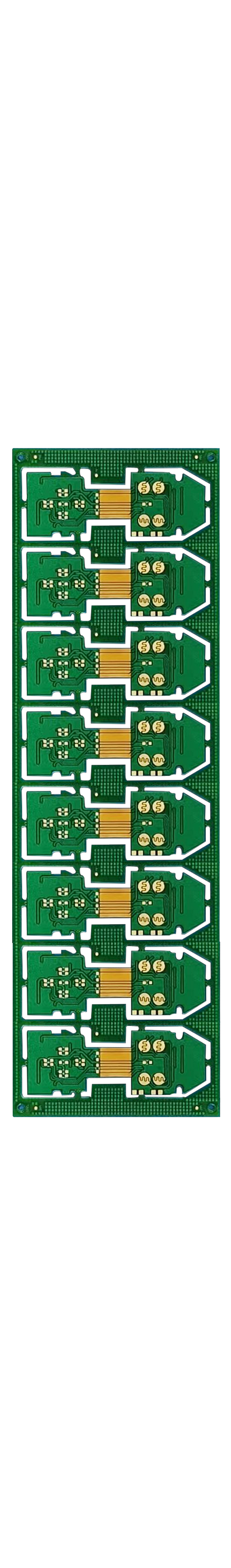

New Energy Battery

| Technical requirements | ||||||

| Product type | Double-sided Flexible PCB + Pure Nickel Sheet | |||||

| Number of layer | 2 Layers | |||||

| Line width and line spacing |

0.15MM/0.1MM | |||||

| Plate thickness | FPC=0.15MM T=1.6MM | |||||

| Copper Thickness | 1OZ | |||||

| Film Thickness | 50UM | |||||

| Surface Treatment | ENG 2-3U | |||||

| Tolerance Requirements | 0.1MM | |||||

| Size | 658*41MM | |||||

| Characteristic | NickelSheet 0.3mm/PI Film 100um | |||||

| Functional testing | AOI/four-wire/continuity/copper slices | |||||

| Application Vehicle | Toyota | |||||

| Application | New Energy Battery | |||||

Application showcase

Front and Rear Car Lights

| Technical requirements | ||||||

| Product type | Single-sided Flex PCB | |||||

| Number of layer | 1 Layer | |||||

| Line width and line spacing |

1.8MM/0.5MM | |||||

| Plate thickness | FPC=0.15MM T=1.15MM | |||||

| Film Thickness | 50UM | |||||

| thermal conductivity | 3.00 | |||||

| Surface Treatment | ENG 2-3U | |||||

| Copper thickness | 1OZ | |||||

| Stiffness | aluminum sheet 1.0mm | |||||

| Characteristic | Aluminum sheet is drawn and combined with thermal adhesive. | |||||

| Application Vehicle | BYD | |||||

| Application | Front and Rear Car Lights | |||||

Application showcase

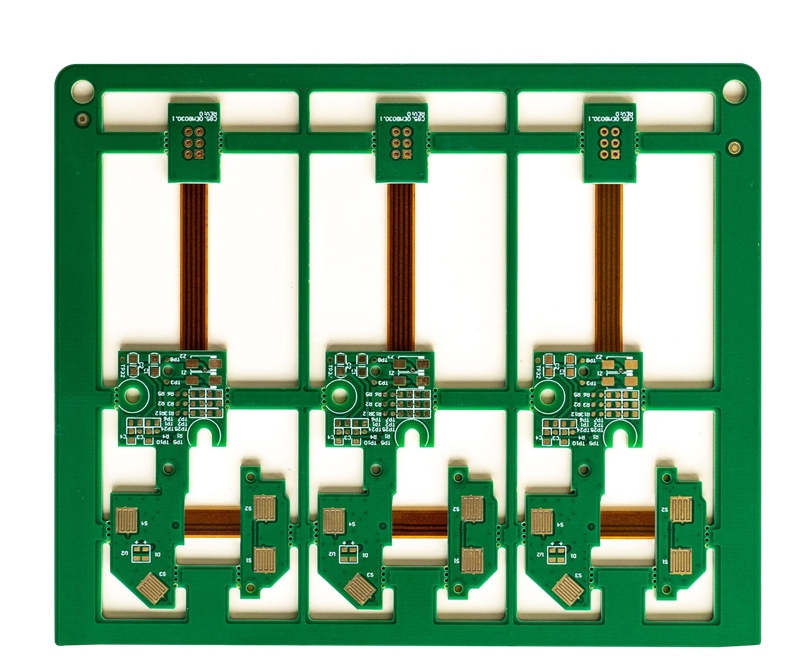

Car Combination Switch Lever

Application showcase

| Technical requirements | ||||||

| Product type | Rigid Flex Printed Circuit Board | |||||

| Number of layer | 2 Layers | |||||

| Line width and line spacing |

0.15MM/0.1MM | |||||

| Plate thickness | FPC=0.15MM T=1.6MM | |||||

| Copper Thickness | 1OZ | |||||

| Film Thickness | 50UM | |||||

| Surface Treatment | ENG 2-3U | |||||

| Tolerance Requirements | 0.1MM | |||||

| Material | Shengyi TG170 copper clad laminate | |||||

| Characteristic | High adhesion, high reliability | |||||

| Functional testing | AOI/four-wire/continuity/copper slices | |||||

| Application Vehicle | GAC Motor | |||||

| Application | Car Combination Switch Lever | |||||

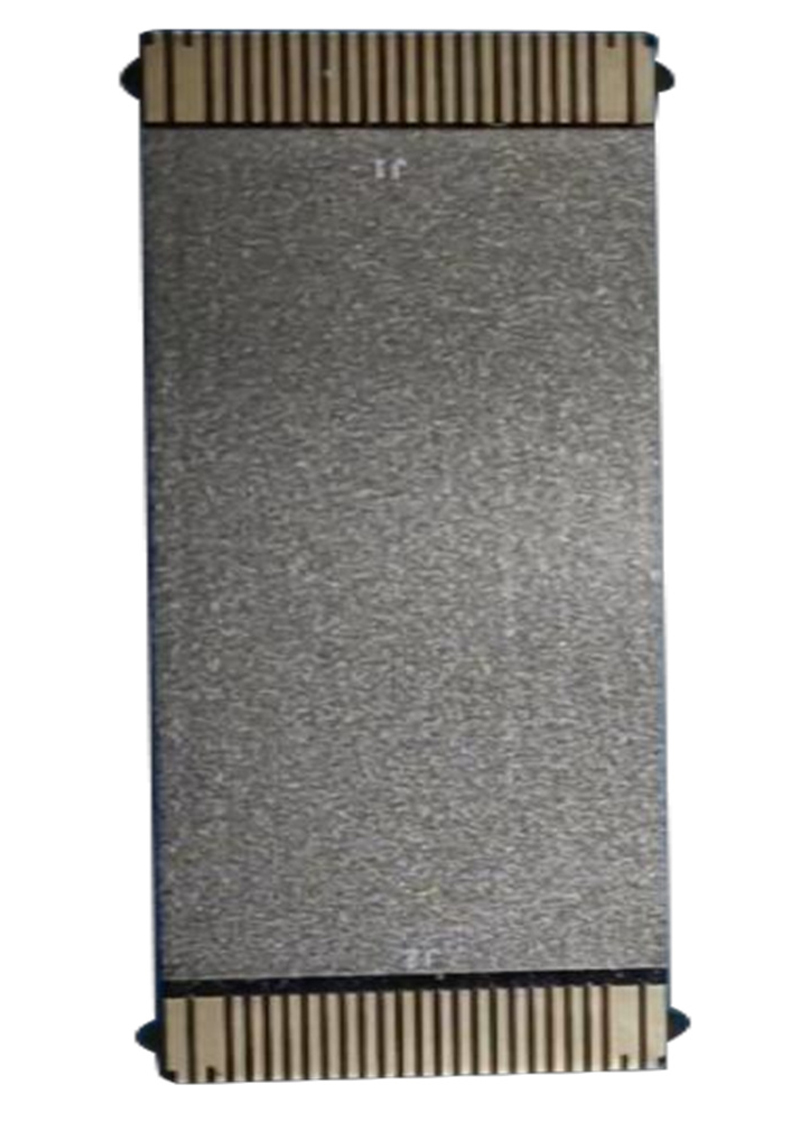

Car Backup Radar

Application showcase

| Technical requirements | ||||||

| Product type | Rigid Flexible Board | |||||

| Number of layer | 2 Layers | |||||

| Line width and line spacing |

0.15MM/0.1MM | |||||

| Plate thickness | FPC=0.15MM T=1.6MM | |||||

| Copper Thickness | 1OZ | |||||

| Film Thickness | 50UM | |||||

| Surface Treatment | ENG 2-3U | |||||

| Precision Tolerance | 0.1MM | |||||

| Material | Panasonic material/TG150 FR-4 | |||||

| Withstand Voltage | 3000V | |||||

| Functional testing | AOI/four-wire/continuity/copper slices | |||||

| Application Vehicle | Cars made by Japan | |||||

| Application | Car Backup Radar | |||||

Car Gear Shift Knob

Application showcase

| Technical requirements | ||||||

| Product type | Flexible Circuit Board+ Stiffness | |||||

| Number of layer | 2 Layers | |||||

| Line width and line spacing |

0.15MM/0.1MM | |||||

| Plate thickness | FPC=0.15MM T=1.15MM | |||||

| Copper Thickness | 1OZ | |||||

| Film Thickness | 27.5UM | |||||

| Surface Treatment | ENG 2-3U | |||||

| Tolerance Requirements | 0.075MM | |||||

| Stiffness | TG150 epoxy board | |||||

| Characteristic | Strict Tolerance Requirements, High Precision. | |||||

| Functional testing | AOI/four-wire/continuity/copper slices | |||||

| Application Vehicle | BAIC | |||||

| Application | Car Gear Shift Knob | |||||

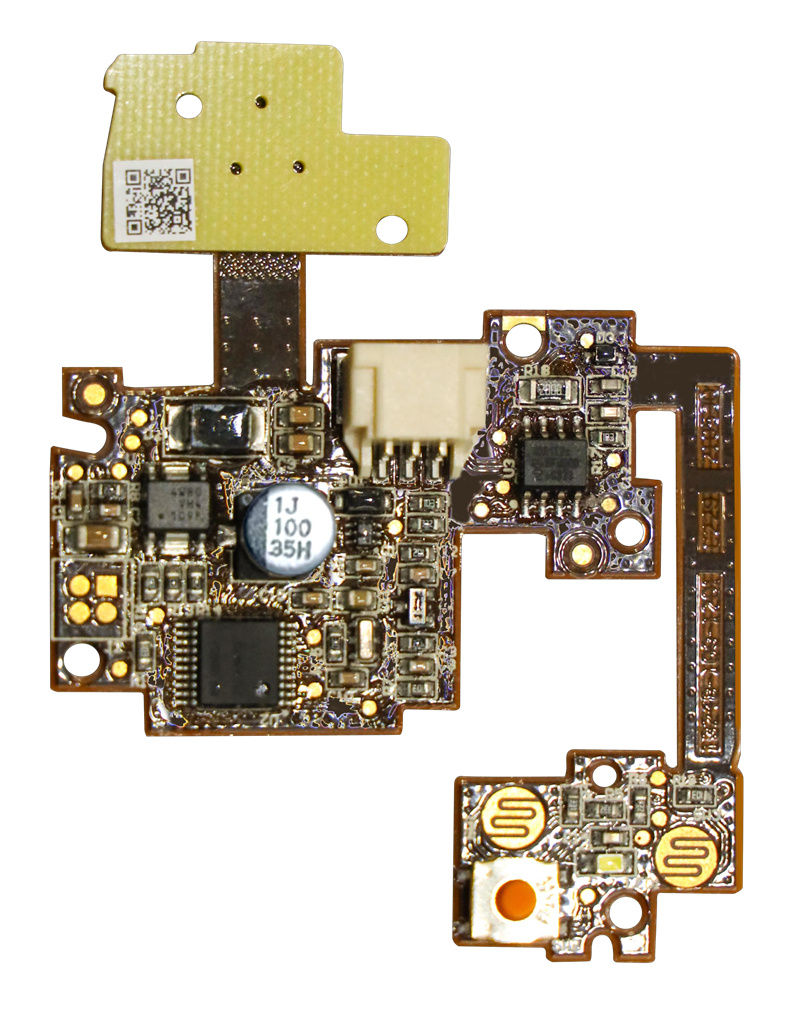

Car Gear Shift Knob

Application showcase

| Technical requirements | ||||||

| Product type | Rigid Flex PCB | |||||

| Number of layer | 4 Layers | |||||

| Line width and line spacing |

0.15MM/0.1MM | |||||

| Plate thickness | FPC=0.15MM T=1.6MM | |||||

| Copper Thickness | 1OZ | |||||

| Film Thickness | 27.5UM | |||||

| Surface Treatment | ENG 2-3U | |||||

| Tolerance Requirements | 0.075MM | |||||

| Stiffness | TG150 epoxy board | |||||

| Characteristic | Strict Tolerance Requirements, High Precision. | |||||

| Functional testing | AOI/four-wire/continuity/copper slices | |||||

| Application Vehicle | Toyota | |||||

| Application | Car Gear Shift Knob | |||||

Intelligent Driving Vision System

Application showcase

| Technical requirements | ||||||

| Product type | Multilayer Flex PCB | |||||

| Number of layer | 3 Layers | |||||

| Line width and line spacing |

0.15/0.15MM | |||||

| Plate thickness | 0.2MM | |||||

| Minimum aperture | 0.15MM | |||||

| Hole copper thickness |

12-15UM | |||||

| Surface Treatment | ENG 2U | |||||

| Copper thickness | 1OZ | |||||

| Licensed Materials | EMS120S-200 | |||||

| Characteristic | Electromagnetic conversion action for absorbing noise and reducing interference. |

|||||

| Application Vehicle | Volkswagen | |||||

| Application | Unmanned Vehicle Vision System | |||||

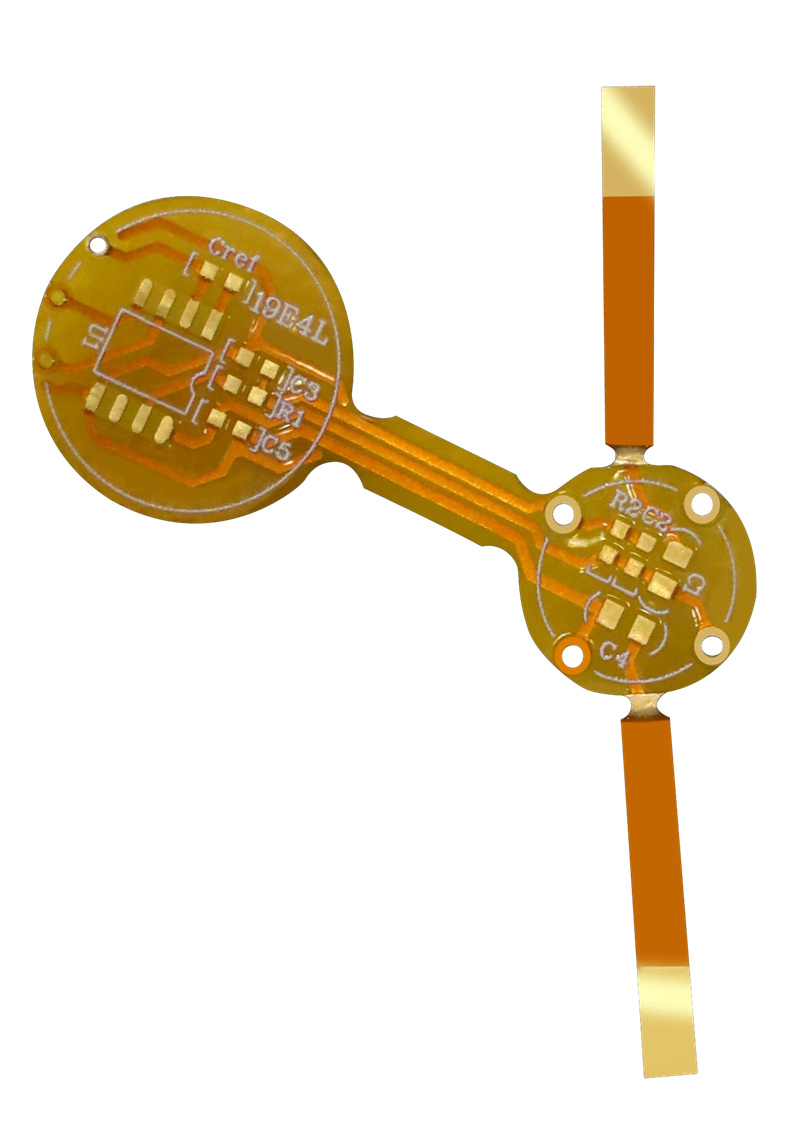

Automotive Sensor

Application showcase

| Technical requirements | ||||||

| Product type | Single-sided Flex PCB | |||||

| Number of layer | 1 Layers | |||||

| Line width and line spacing |

0.2/0.25MM | |||||

| Plate thickness | 0.18MM | |||||

| Film Thickness | 50UM | |||||

| Hole copper thickness |

1OZ | |||||

| Surface Treatment | ENG 2-3U | |||||

| Franchise requirements | High temperature 135 degrees, no carbonization for 200 hours |

|||||

| Surface requirements | 48-hour salt spray test | |||||

| Characteristic | Corrosion-resistant High-temperature-resistant |

|||||

| Application Vehicle | Volkswagen | |||||

| Application | Automotive Sensor | |||||

Car Gear Shift Knob

| Technical requirements | ||||||

| Product type | Rigid Flex Circuit Board | |||||

| Number of layer | 2 Layers | |||||

| Line width and line spacing |

0.15MM/0.1MM | |||||

| Plate thickness | FPC=0.15MM T=1.6MM | |||||

| Copper Thickness | 1OZ | |||||

| Film Thickness | 50UM | |||||

| Surface Treatment | ENG 2-3U | |||||

| Tolerance Requirements | 0.1MM | |||||

| Material | Shengyi TG170 Copper-clad laminate | |||||

| Characteristic | High adhesion, high reliability | |||||

| Functional testing | AOI/four-wire/continuity/copper slices | |||||

| Application Vehicle | Cars made by Japan | |||||

| Application | Car Gear Shift Knob | |||||

Application showcase