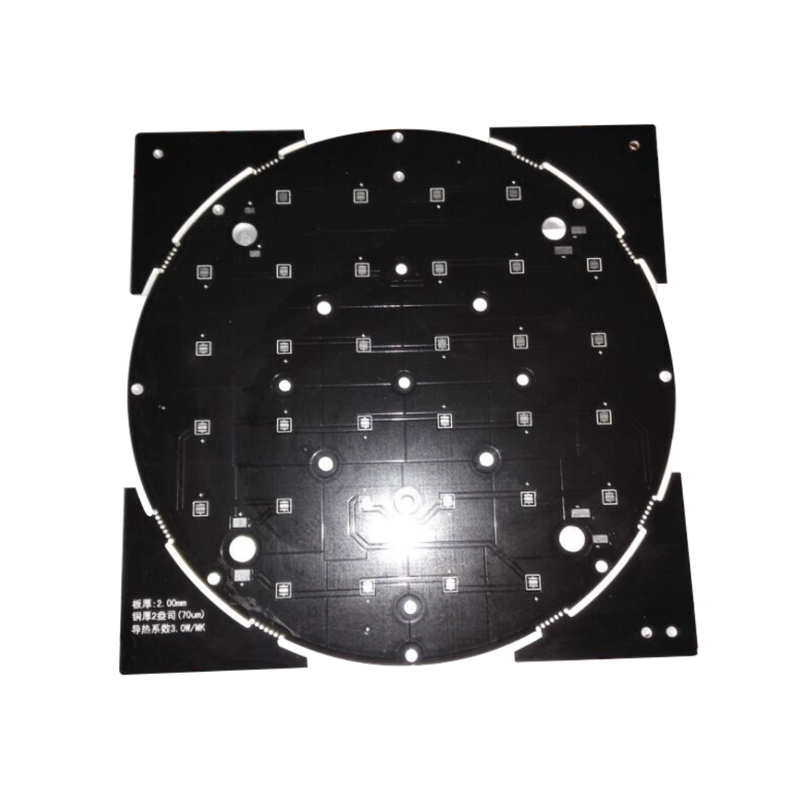

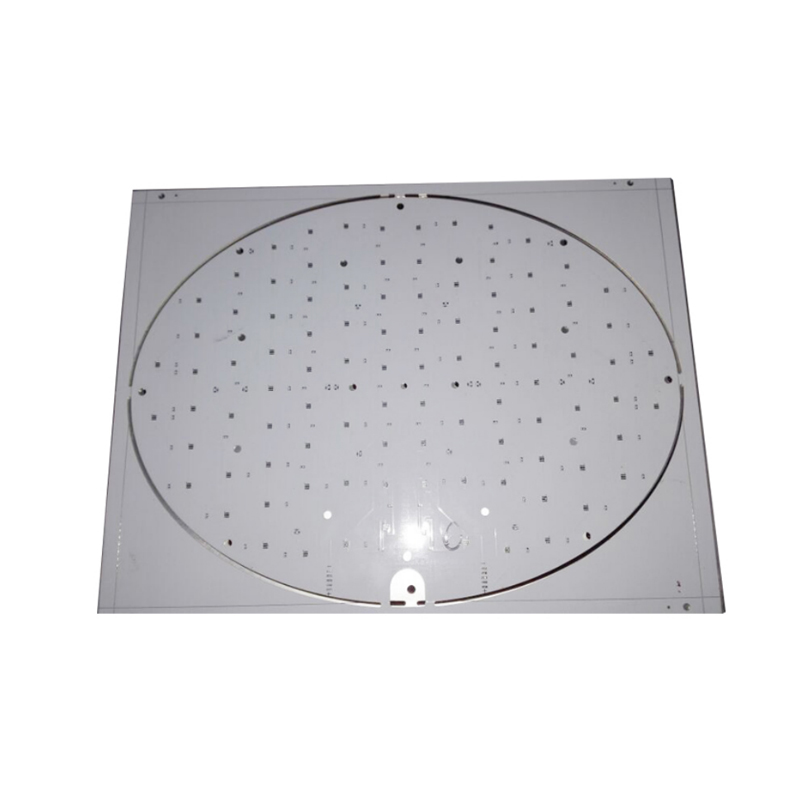

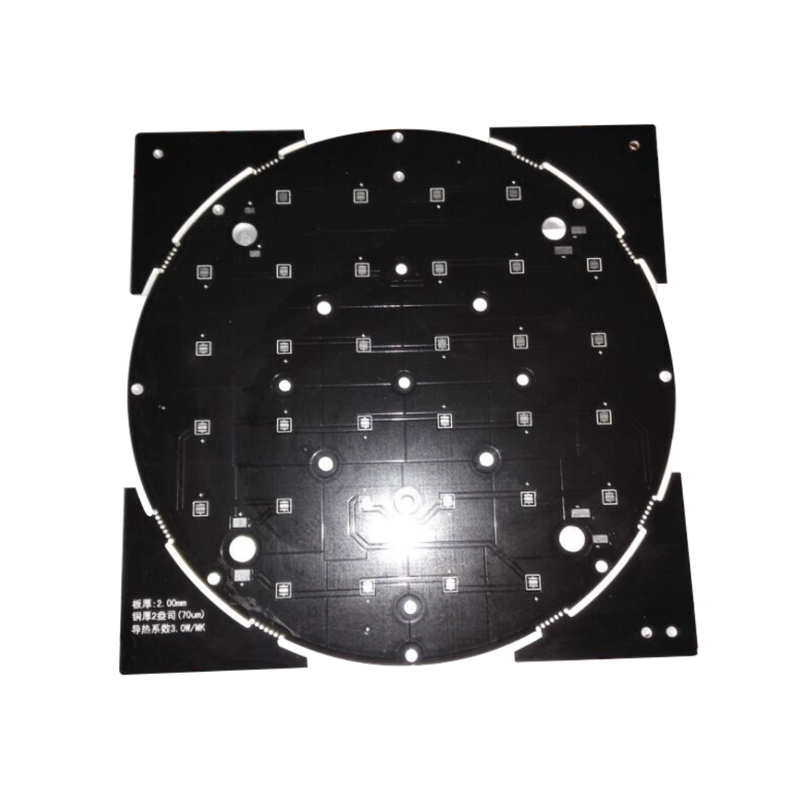

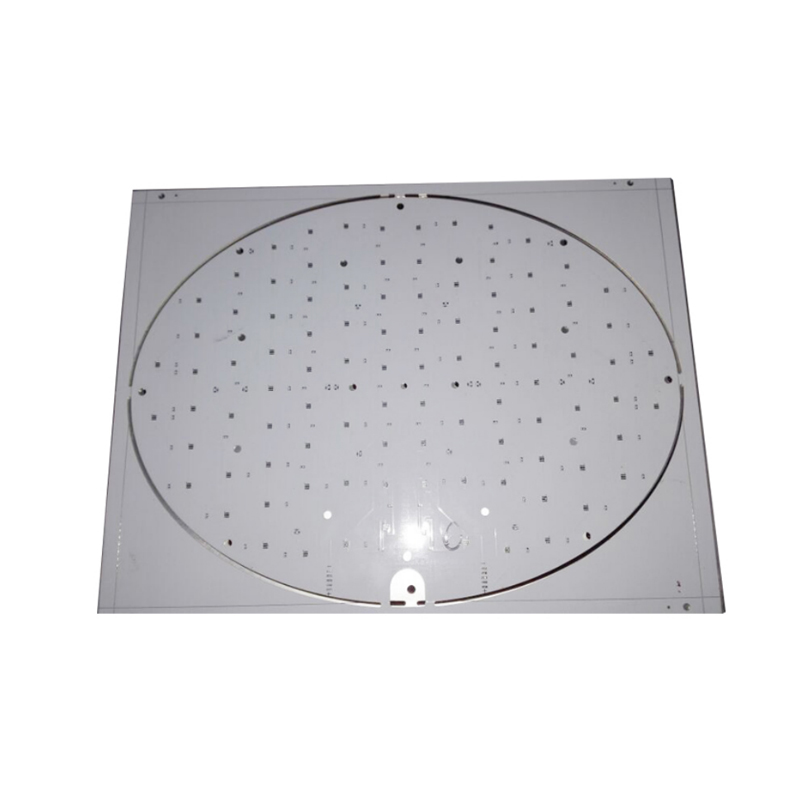

Single-Layer Aluminum PCB Board Quick Turn Pcb Manufacturers

Short Description:

Model: 1 layer Aluminum PCB Board

Product application: Industry Control

Board Layers: 1 layer

Base material: Aluminum

Inner Cu thickness:/

Quter Cu thickness: 35um

Solder mask color: White

Silkscreen color:/

Surface treatment: LF HASL

PCB thickness: 1.6mm +/-10%

Min Line width/space: 0.2/0.2mm

Min hole: 0.75

Blind hole:/

Buried hole:/

Hole tolerance(mm): PTH: 土0.076, NTPH: 0.05

Impedance:/

PCB Process Capability

| No. | Project | Technical indicators |

| 1 | Layer | 1-60(layer) |

| 2 | Maximum processing area | 545 x 622 mm |

| 3 | Minimumboardthickness | 4(layer)0.40mm |

| 6(layer) 0.60mm |

| 8(layer) 0.8mm |

| 10(layer)1.0mm |

| 4 | Minimum line width | 0.0762mm |

| 5 | Minimum spacing | 0.0762mm |

| 6 | Minimum mechanical aperture | 0.15mm |

| 7 | Hole wall copper thickness | 0.015mm |

| 8 | Metallized aperture tolerance | ±0.05mm |

| 9 | Non-metallized aperture tolerance | ±0.025mm |

| 10 | Hole tolerance | ±0.05mm |

| 11 | Dimensional tolerance | ±0.076mm |

| 12 | Minimum solder bridge | 0.08mm |

| 13 | Insulation resistance | 1E+12Ω(normal) |

| 14 | Plate thickness ratio | 1:10 |

| 15 | Thermal shock | 288 ℃(4 times in 10 seconds) |

| 16 | Distorted and bent | ≤0.7% |

| 17 | Anti-electricity strength | >1.3KV/mm |

| 18 | Anti-stripping strength | 1.4N/mm |

| 19 | Solder resist hardness | ≥6H |

| 20 | Flame retardancy | 94V-0 |

| 21 | Impedance control | ±5% |

We Do HDI Circuit Board With 15 Years' Experience With Our Professionalism

4 layer Flex-Rigid Boards

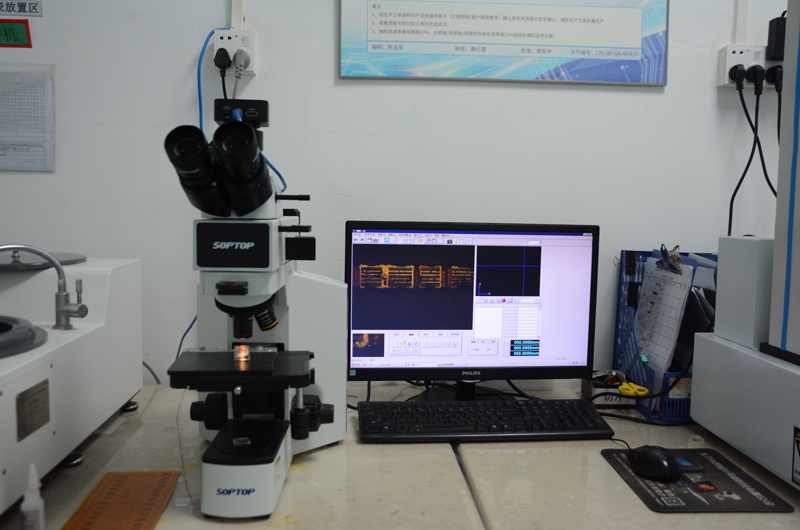

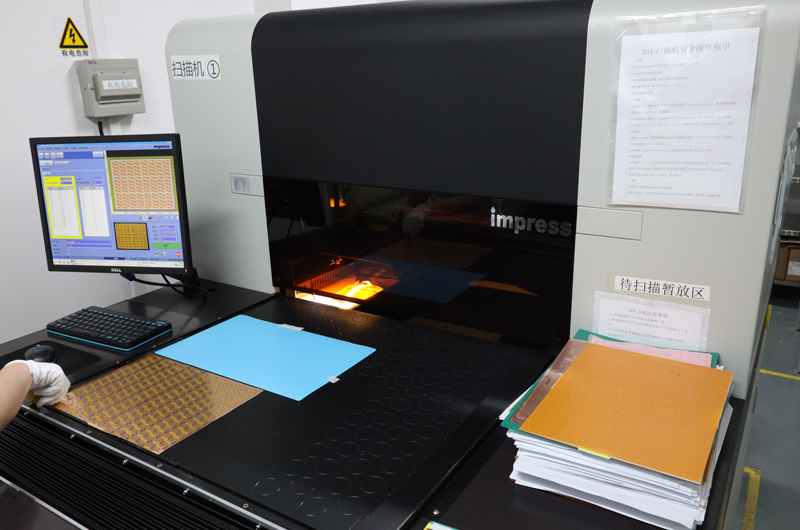

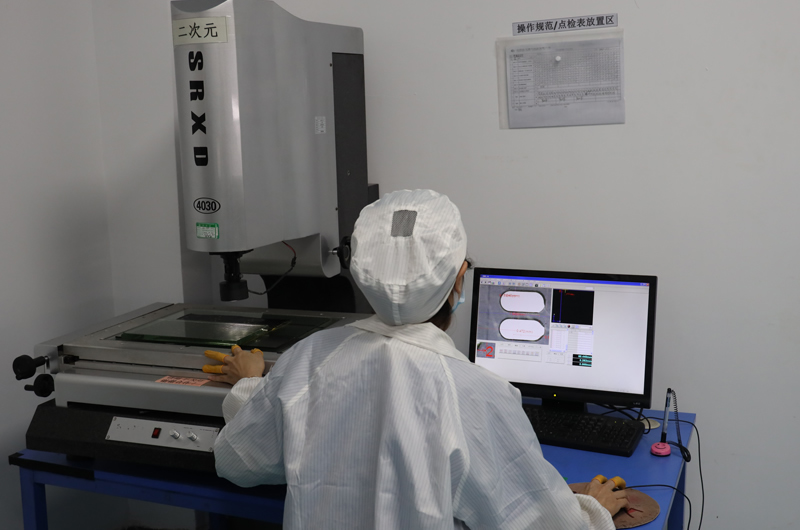

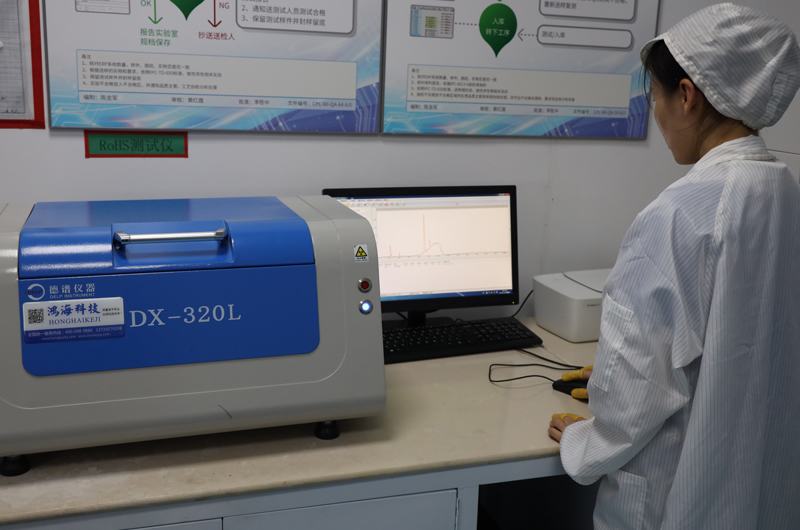

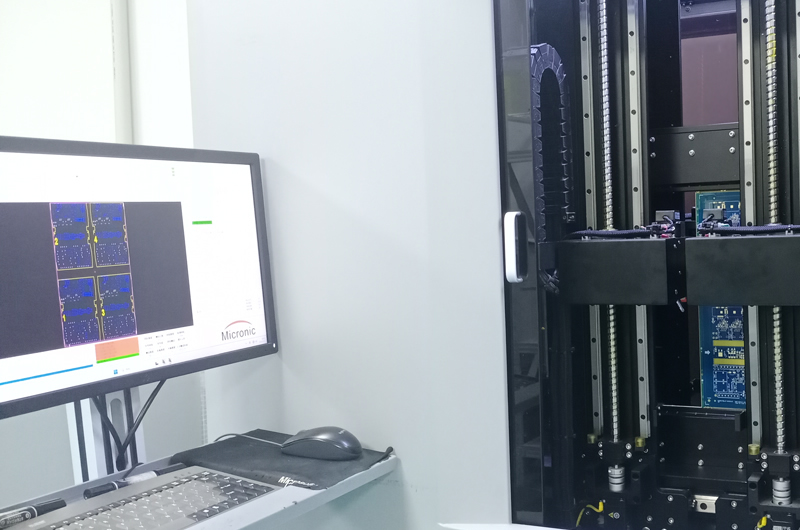

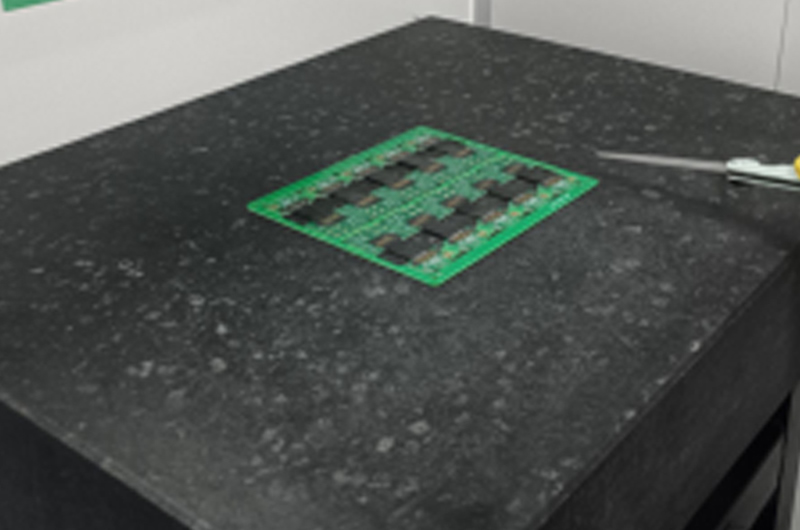

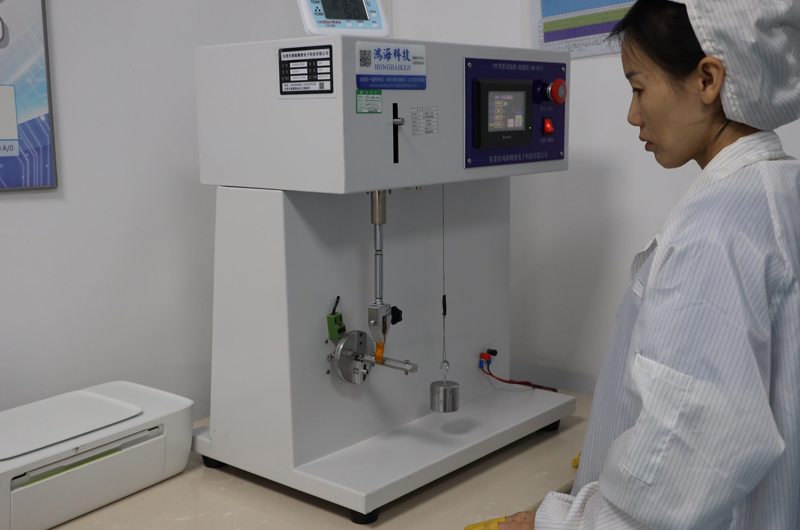

Testing And Inspection Equipment

Our HDI Circuit Board Service

. Provide technical support Pre-sales and after-sales;

. Custom up to 40 layers, 1-2days Quick turn reliable prototyping, Component procurement, SMT Assembly;

. Caters to both Medical Device, Industrial Control, Automotive, Aviation, Consumer Electronics, IOT, UAV, Communications etc.

. Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

How Aluminum PCB Board applicated in industry control

1. Power electronics: Aluminum PCB boards are widely used in power electronic devices such as motor drives, inverters, and power supplies. Aluminum's high thermal conductivity helps to dissipate heat efficiently, thereby improving the performance and reliability of power electronics.

2. LED lighting: Aluminum PCB boards are often used in LED lighting applications, including street lights, high bay lights, and automotive lighting. The excellent thermal conductivity of aluminum helps to dissipate heat efficiently, ensuring longer service life and stable performance of LED lights.

3. Industrial automation: Aluminum PCB boards are used in various industrial automation systems, including control panels, PLC modules, motor controllers, etc. The lightweight and compact nature of aluminum PCBs makes them suitable for space-constrained environments.

4. Robotics: Aluminum PCB boards are used for motor control, sensor interface and power distribution in robotics. The thermal properties of aluminum help dissipate the heat generated by generators and power electronics, ensuring stable and reliable operation of robotic systems.

5. HVAC systems: Heating, ventilation and air conditioning (HVAC) systems are often controlled and monitored using aluminum PCB boards. Aluminum's thermal properties help manage the heat generated by components and ensure efficient operation of HVAC systems.

6. Industrial control panels: Aluminum PCB boards are used in industrial control panels to monitor and control various processes in manufacturing, oil and gas, power generation and other industries. The durability and reliability of aluminum PCBs make them suitable for harsh industrial environments.

Aluminum PCB Board applicated in industry control

7. Solar power generation system: Aluminum PCB board is used for solar panel inverter and control system.

Aluminum's high thermal conductivity helps dissipate the heat generated by the power electronics in solar inverters, ensuring efficient energy conversion.

8. Automotive electronics: Aluminum PCB boards are used in automotive control systems, such as engine control units (ECU), ABS systems, and powertrain control modules. The light weight and heat dissipation properties of aluminum PCBs make them suitable for automotive applications.

9. Renewable energy systems: Aluminum PCB boards are used in various renewable energy systems, including wind turbines and hydroelectric power systems, for control and monitoring purposes. Aluminum PCBs are robust and well suited to withstand harsh environmental conditions.

10. Medical equipment: Aluminum PCB boards are used in medical devices and equipment, such as patient monitoring systems, surgical instruments, and laboratory equipment. The reliability and thermal management capabilities of aluminum PCBs are critical to maintaining accurate and stable performance in medical applications.

11. Telecommunications equipment: Aluminum PCB boards are used in telecommunications equipment, including base stations, radio frequency (RF) amplifiers, and network infrastructure. Aluminum's thermal properties are important for efficient heat dissipation in these high power applications.

12. Aerospace: Aluminum PCB boards are used in aerospace systems, including flight control systems, avionics and satellite components. The lightweight nature of aluminum PCBs combined with their excellent thermal and electrical properties make them suitable for aerospace applications.

Related products