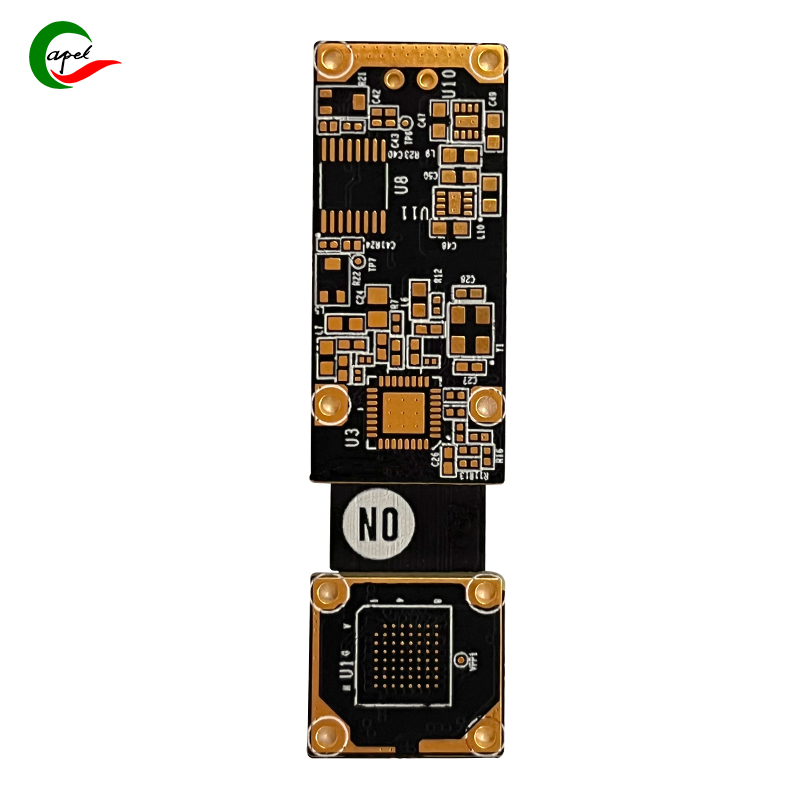

8 layer Flex Board Pcb Special Process NiPdAu Printed Circuit Copper Thickness 18um

How Capel's 8 Layer Flex Board Pcb Special Process NiPdAu Printed Circuit Copper Thickness 18um Provides Reliability Solutions for New Energy Automakers

-Capel with 15 years of professional technical experience-

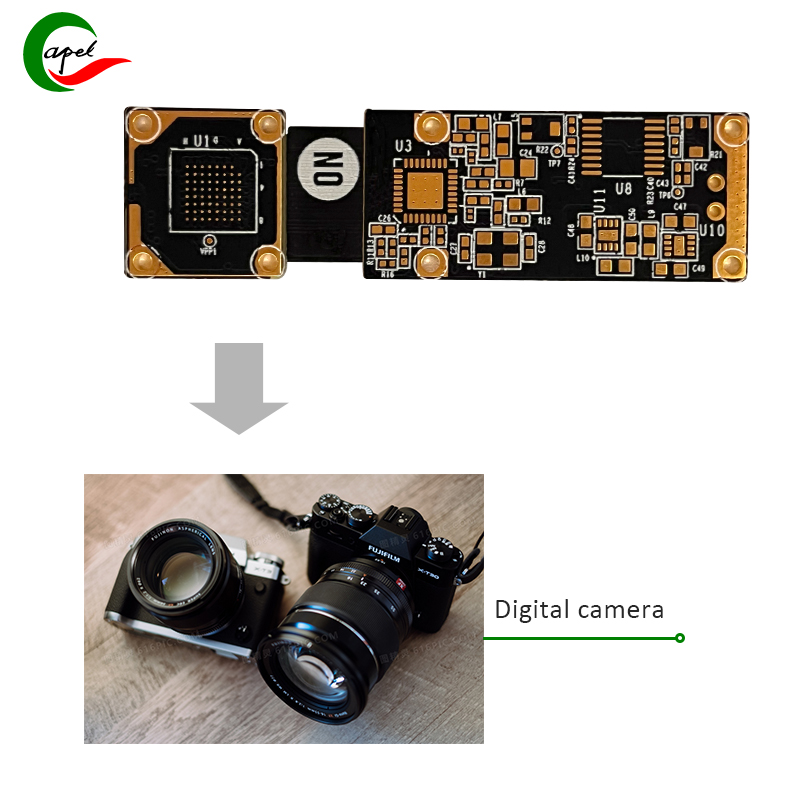

8-layer PFC flexible circuit: revolutionizing the digital camera industry

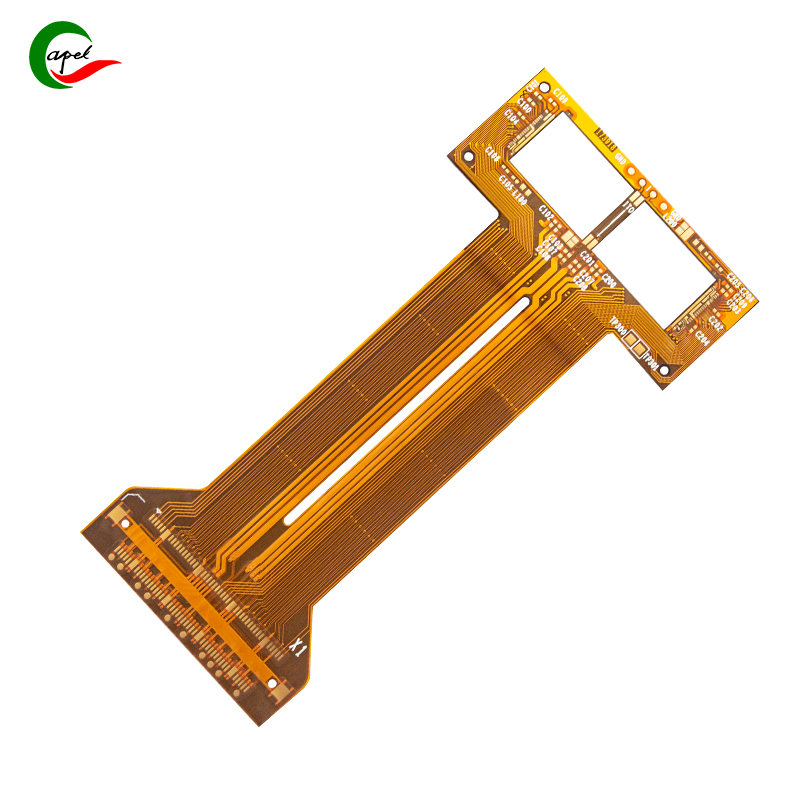

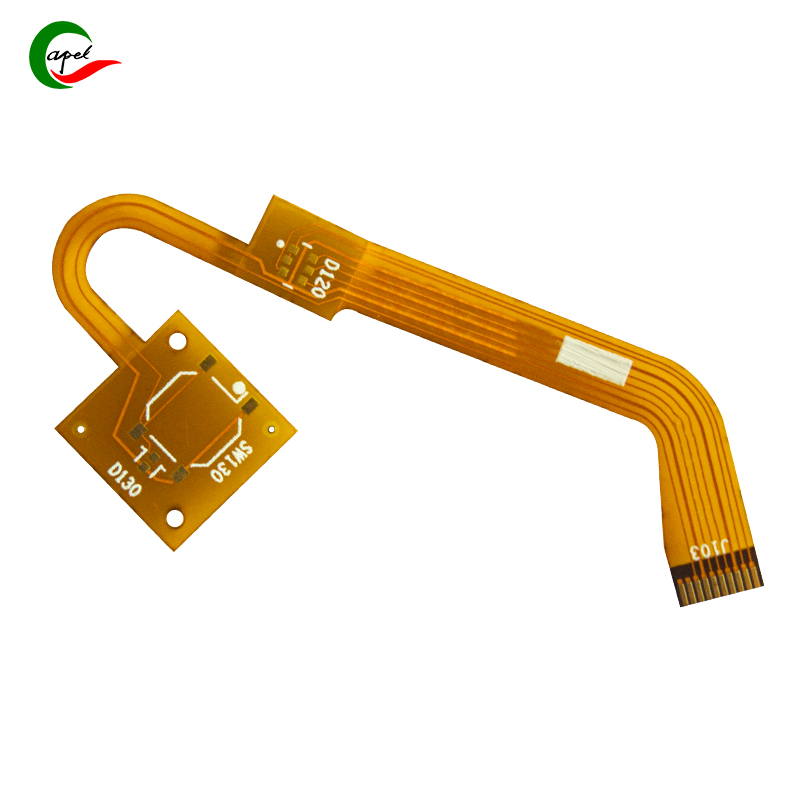

These 8-layer PFC flex circuits are designed to meet the demanding requirements of modern digital cameras. The product type is 8-layer flexible board PCB, providing unparalleled performance and reliability. Let's take a closer look at the features that make these circuits the first choice among digital camera manufacturers.

One of the key factors in the excellent performance of these circuits is their line width and spacing. Their line width and line spacing are 0.075mm/0.075mm, ensuring smooth flow of signals, minimizing interference and maximizing clarity. This means your digital camera will deliver crystal-clear images and videos, ensuring you capture every precious moment with the utmost precision.

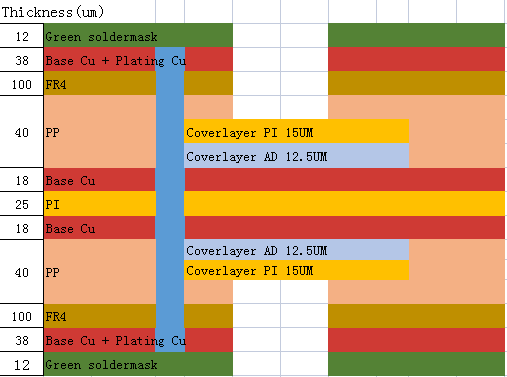

In addition, these circuits have a board thickness of 0.3 mm, making them lightweight and flexible. Not only does this allow for greater design flexibility, it also ensures that the circuit can meet the needs of modern digital cameras. Whether you're shooting in extreme temperatures or challenging environments, these circuits will continue to operate flawlessly.

When it comes to aperture size, precision is key. The minimum aperture of 0.15mm ensures that the circuit can accurately transmit signals for sharp focus and excellent image quality. No more blurry or distorted images - with 8-layer PFC flexible circuitry, every shot will look perfect.

Additionally, the copper thickness of these circuits is 18um. Copper is an excellent conductor of electricity, and thick copper layers enhance signal transmission and reduce signal loss. This means your digital camera will have faster, more reliable data transfer, ensuring smooth operation and fast response times.

To ensure the highest safety standards, these circuits are flame retardant with class 94V0. This means they are fire-resistant, adding an extra layer of protection to your digital camera. You can rest easy knowing your equipment can withstand any unforeseen circumstances.

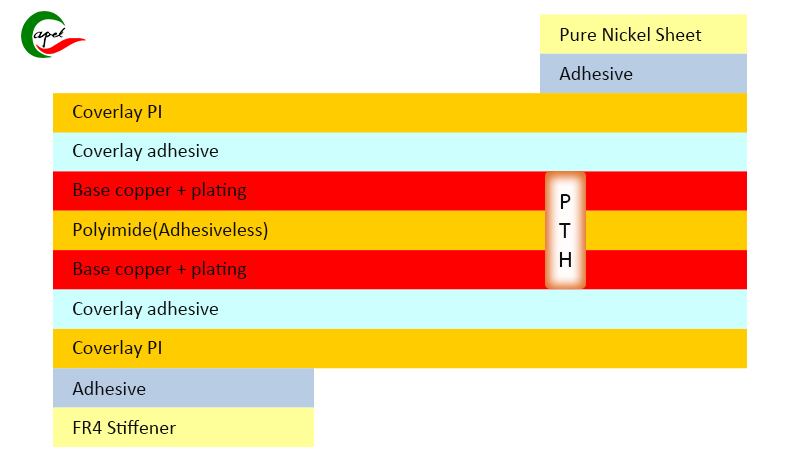

The finish on these circuits is immersed gold. Gold plating provides excellent electrical conductivity and ensures corrosion resistance, which is essential for the longevity of a digital camera. In addition, immersion gold provides a smooth surface finish, prevents oxidation and ensures long-term stable performance.

In terms of resistance welding colors, these circuits are available in black. This adds a touch of elegance and sophistication to your digital camera design, giving it a sleek and modern look. With 8-layer PFC flex circuits, your device not only performs well, but also stands out from the crowd.

Stiffness is another key factor to consider with flexible circuits. The stiffness of FR4 ensures that the circuit maintains its shape even when bent or twisted. This allows for greater design flexibility and ensures your digital camera can adapt to a variety of form factors without compromising performance.

Finally, these circuits undergo a special process called NiPdAu. The process involves plating nickel, palladium and gold, further enhancing the conductivity and reliability of the circuit. Through this special process, your digital camera will have superior signal integrity, resulting in outstanding image quality and overall performance.

The application range of 8-layer PFC flexible circuits is not limited to digital cameras. They are also widely used in smartphones, laptops, medical equipment, and many other advanced electronic devices that require high-performance PCBs. Their versatility and robustness make them ideal for manufacturers in a variety of industries.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Rigid Flexible Circuit Board with 15 years of experience with our professionalism

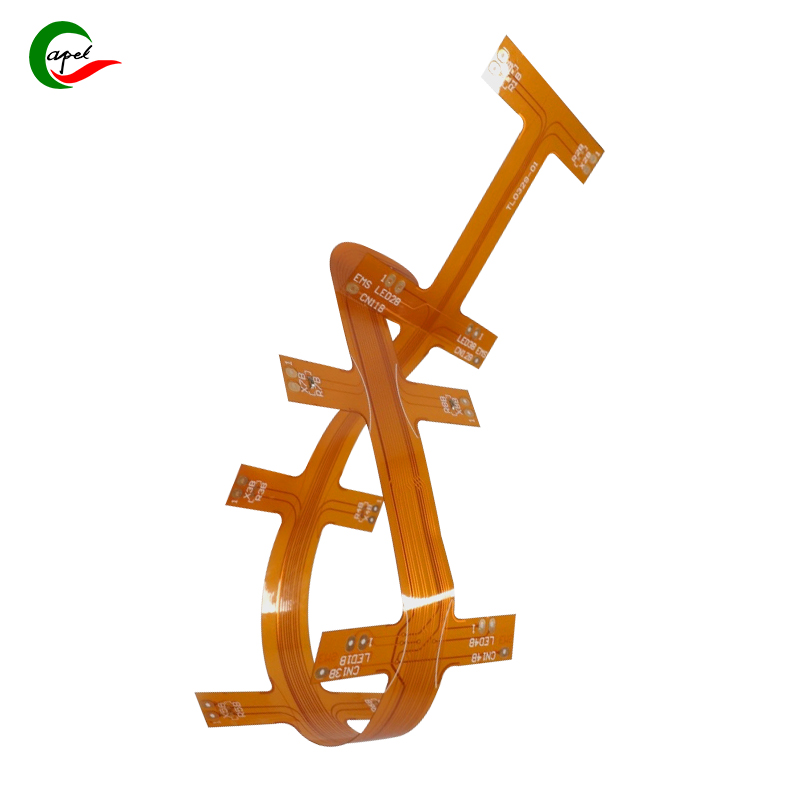

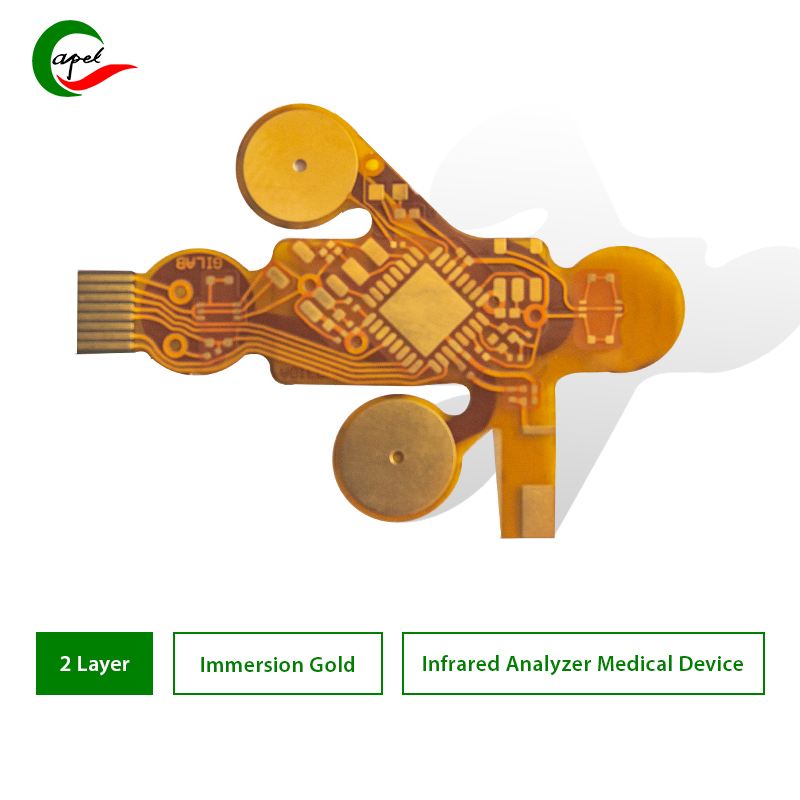

2 Layers Double-sided Fpc Pcb

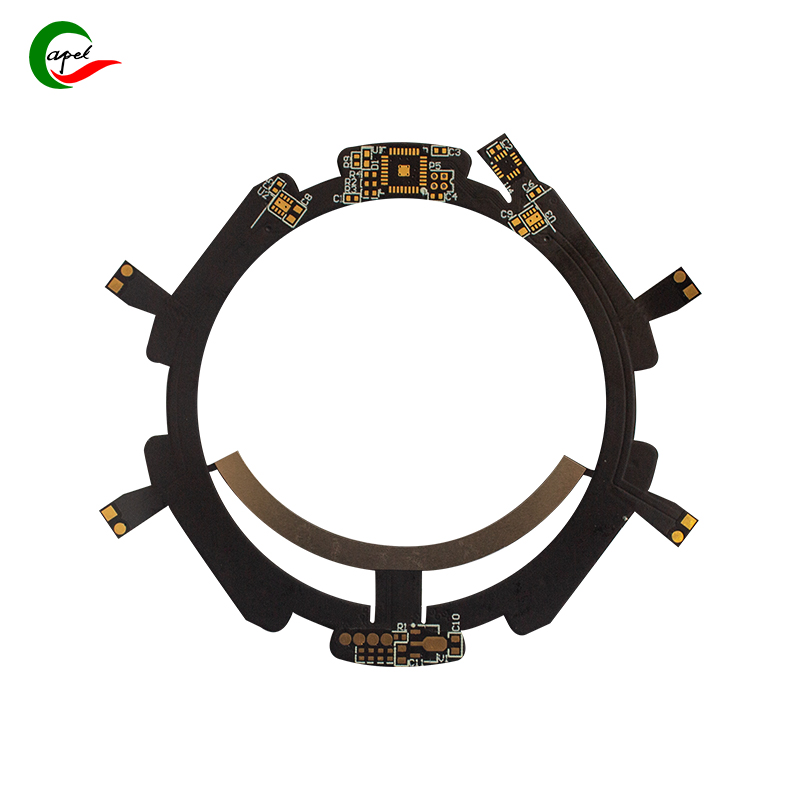

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.