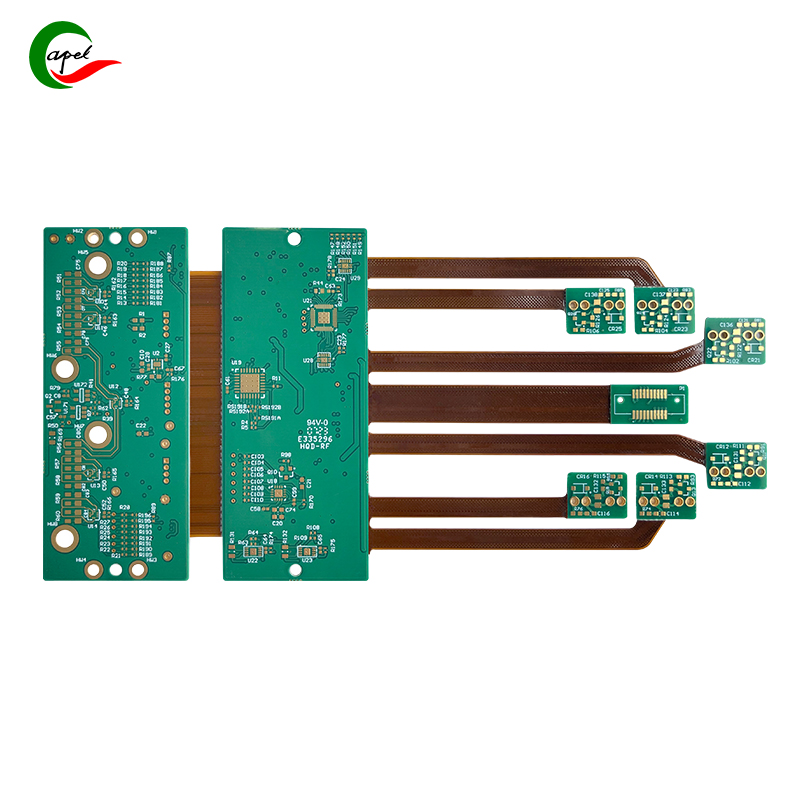

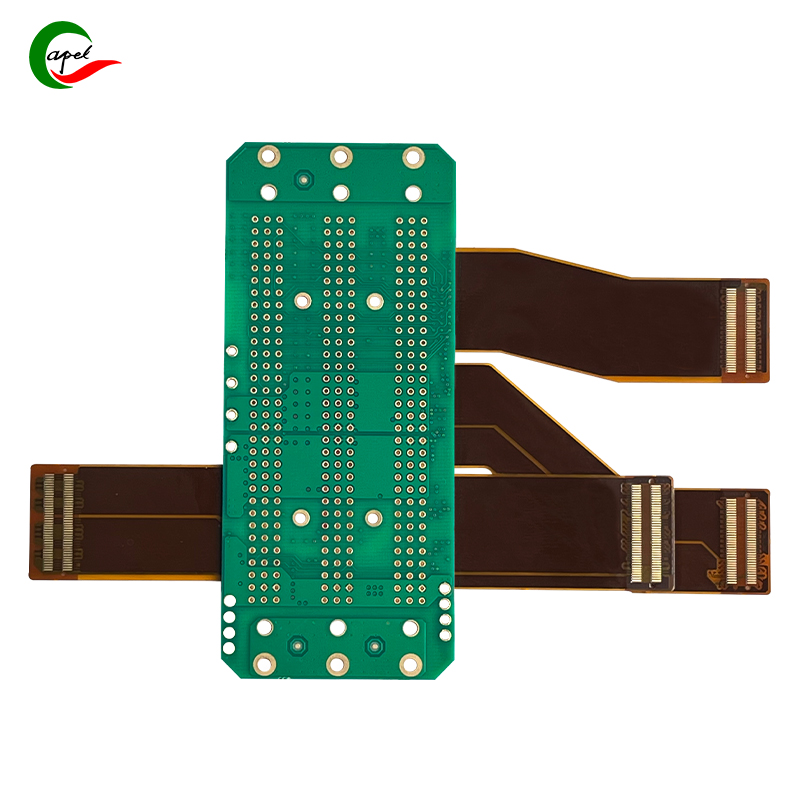

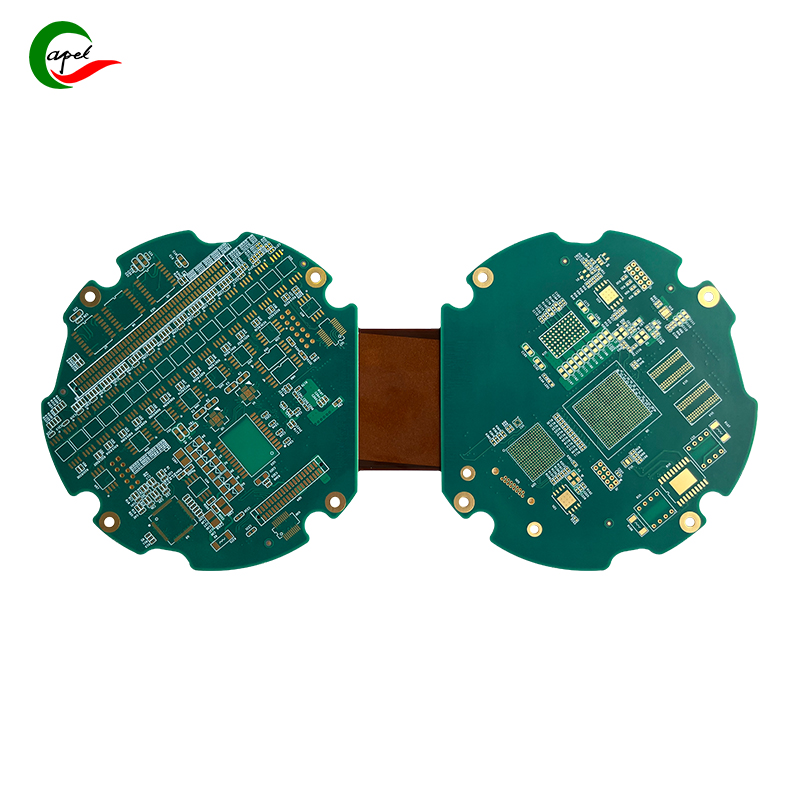

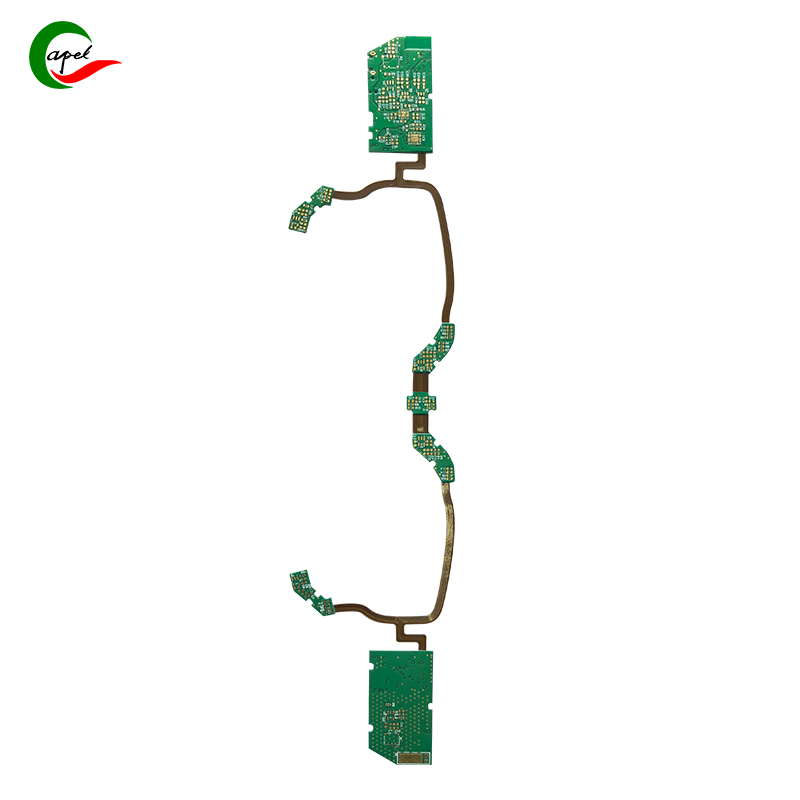

6 layer Rigid-Flex Printed Circuit Boards Pcb Manufacturing for Night Vision Goggles

How Capel's 6 Layer Rigid-Flex Printed Circuit Boards Pcb Manufacturing Provides Reliability Solutions for Night Vision Goggles manufacturers

-Capel with 15 years of professional technical experience-

Introducing our state-of-the-art 6-layer rigid-flex printed circuit board designed specifically for night vision goggle equipment. Combining the latest technology with precision engineering, our circuit boards are the perfect solution for high-performance, reliable and durable night vision equipment.

Our boards are 1.2mm thick to withstand rigorous use and ensure optimal functionality. The 2+2+2 layer stacking enables efficient power distribution and signal transmission, resulting in enhanced performance and superior image quality.

With a minimum hole diameter of 0.2 mm, our boards provide superior accuracy and precision in complex component assembly. 0.15mm/0.15mm line width and line spacing ensure seamless connection and minimize signal loss.

Our circuit boards are designed to withstand harsh environments and extreme temperatures, making them ideal for night vision applications. Its impedance-free design ensures uninterrupted signal flow for clear, sharp and uninterrupted images.

To further enhance its durability, we use an ENIG 2-3uin surface treatment, which provides optimal protection against corrosion and extends the life of the board. The 35um copper hole thickness ensures excellent electrical conductivity and efficient heat dissipation.

Our circuit boards have a warpage tolerance of less than 0.5% and a tolerance accuracy of ±0.1mm, ensuring excellent stability and dimensional accuracy even under the most demanding conditions. This ensures consistent performance and long-term reliability.

Our 6-layer rigid-flex printed circuit boards for night vision goggles are designed and manufactured to the highest industry standards. They undergo rigorous testing and quality control processes to ensure optimal performance and reliability.

Our 6-layer rigid-flex printed circuit board is the perfect choice for night vision goggle devices. With their advanced features, durability and precision engineering, they deliver unparalleled performance and reliability, guaranteeing superior image quality and optimal functionality in night vision applications.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel manufactures customized high-precision Rigid Flexible Circuit Board / Flexible PCB / HDI PCB with 15 years of experience with our professionalism

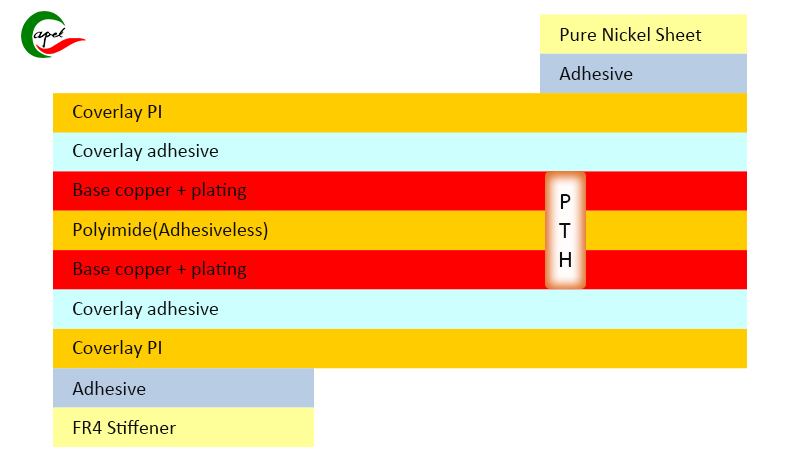

2 Layer Flexible PCB Boards Stackup

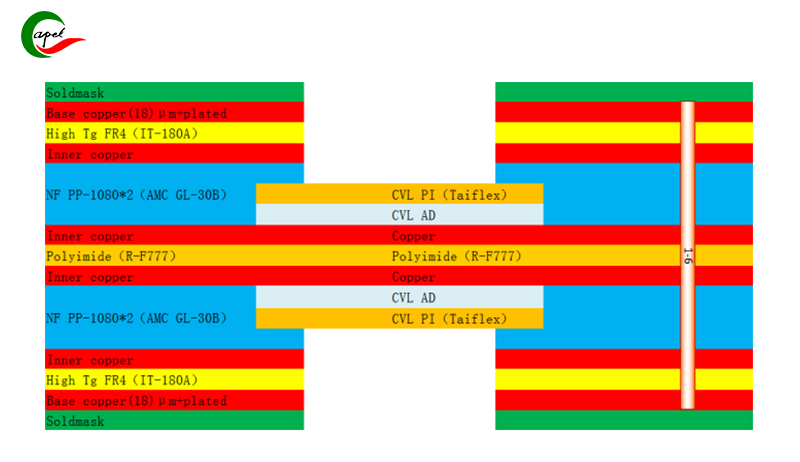

6 layer Rigid-Flex Printed Circuit Boards Stackup

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel provide customers customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.