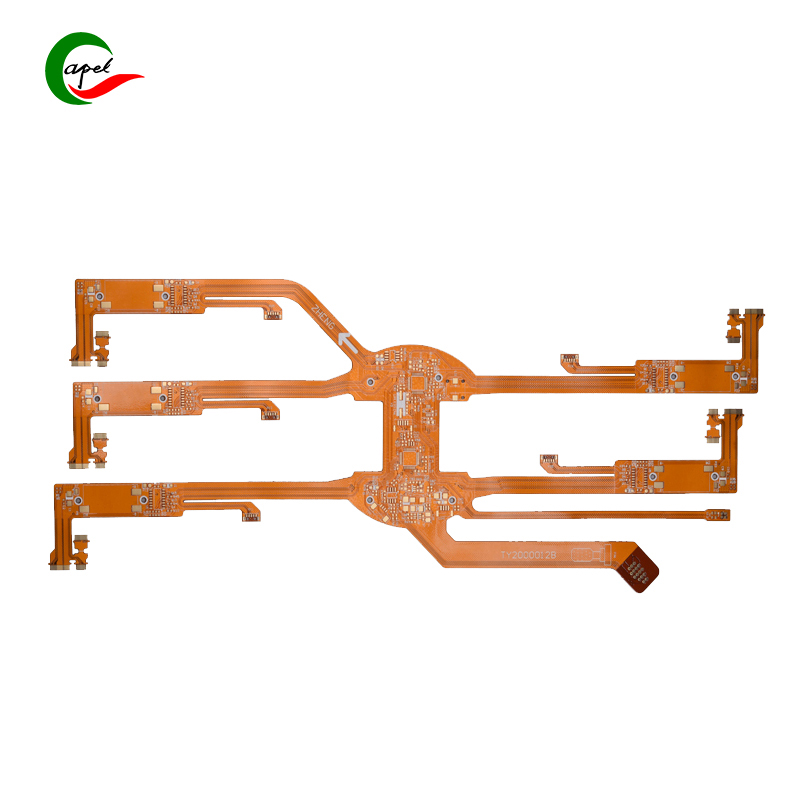

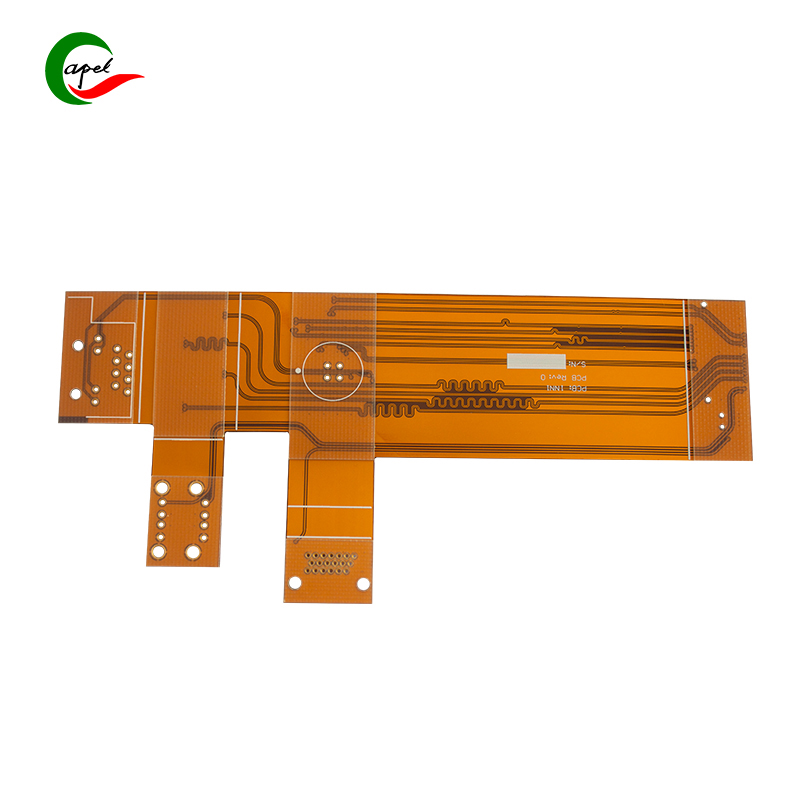

4 Layer Flexible PCBs PI Multilayer FPCs for Speakers

Specification

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi- layer FPC / Aluminum PCBs Rigid-Flex PCBs |

Layers Number | 1-16 layers FPC 2-16 layers Rigid-FlexPCB HDI Printed Circuit Boards |

| Max Manufacture Size | Single layer FPC 4000mm Doulbe layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

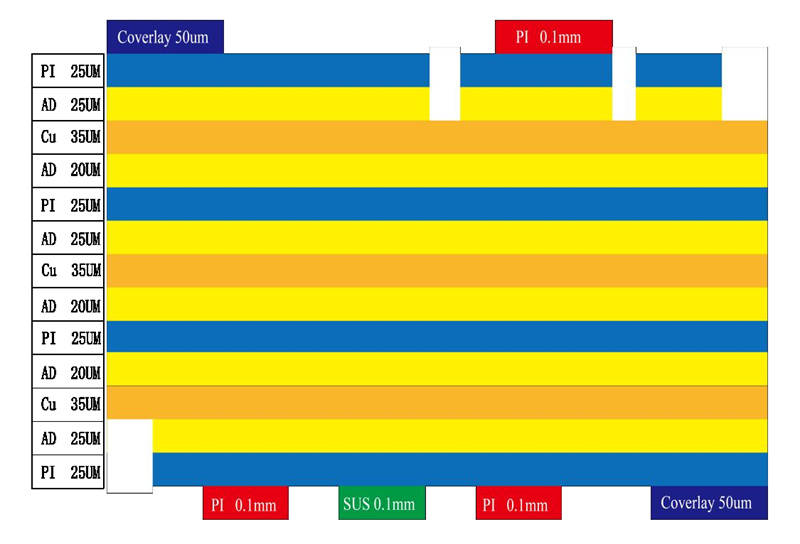

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plat ing/OSP |

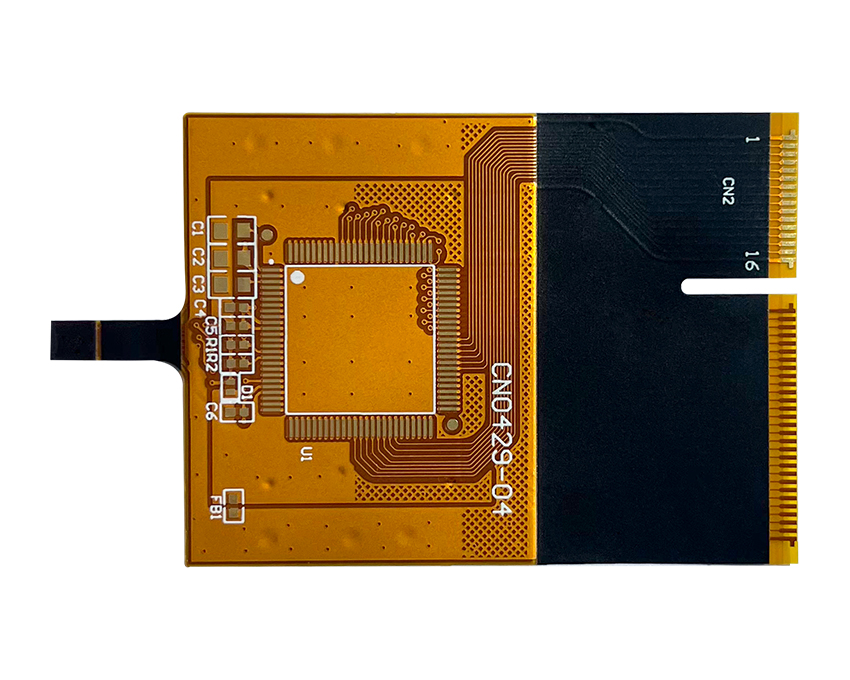

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

We do PI Multilayer FPCs with 15 years' experience with our professionalism

3 layer Flex PCBs

8 layer Rigid-Flex PCBs

8 layer HDI Printed Circuit Boards

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Our PI Multilayer FPCs Service

. Provide technical support Pre-sales and after-sales;

. Custom up to 40 layers, 1-2days Quick turn reliable prototyping, Component procurement, SMT Assembly;

. Caters to both Medical Device, Industrial Control, Automotive, Aviation, Consumer Electronics, IOT, UAV, Communications etc..

. Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

How PI Multilayer FPCs improve technology in speakers

1. Reduced size and weight: PI multilayer FPC is thin and flexible, enabling compact and lightweight design of speakers.

This is especially beneficial for portable speakers where space and weight are key factors.

2. Enhanced signal transmission: PI multilayer FPC has the characteristics of low impedance and low signal loss.

This enables efficient signal transfer between the different components of the speaker system, improving audio quality and fidelity.

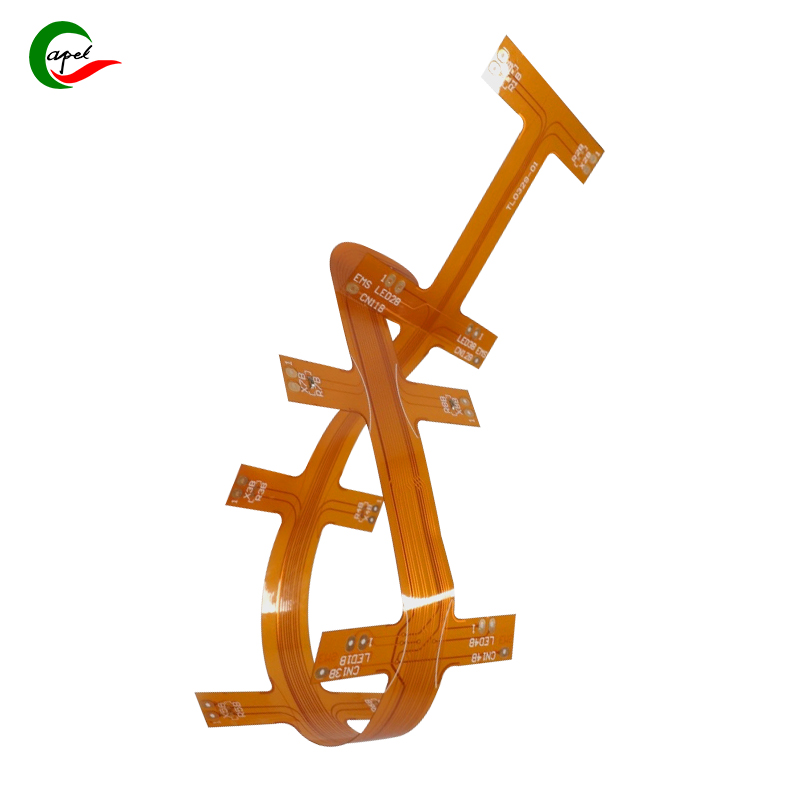

3. Flexibility and Design Freedom: The flexibility of PI's multilayer FPC allows for creative and unconventional designs in loudspeakers. Manufacturers can take advantage of the flexibility to shape and integrate loudspeakers into various form factors, such as curved or irregular surfaces.

4. Durable and reliable: PI multilayer FPC has strong resistance to temperature changes, moisture and mechanical stress.

This makes them more durable and reliable in harsh operating conditions such as outdoors or harsh environments.

5. Easy to integrate: PI multilayer FPC can carry various electronic components and circuits on a flexible board.

This simplifies the assembly and integration process, reduces manufacturing costs and increases overall efficiency.

6. High-frequency performance: PI multi-layer FPC can support high-frequency signals, so that the speaker can accurately reproduce a wider range of audio. This results in improved sound reproduction, especially for high-resolution audio formats.

PI Multilayer FPCs applicate in speakers FAQ

Q: What is PI multilayer FPC?

A: PI multilayer FPC, also known as polyimide multilayer flexible printed circuit, is a flexible circuit board made of polyimide material. They consist of multiple layers of conductive traces separated by insulating layers, allowing the integration of various electronic components and circuits.

Q: What are the advantages of using PI Multilayer FPCs in speakers?

A: PI multilayer FPCs offer several advantages in loudspeakers, including size and weight reduction, improved signal transfer, flexibility and design freedom, durability and reliability, ease of integration, and support for high frequency performance.

Q: How does PI multilayer FPC help reduce speaker size and weight?

A: PI multilayer FPCs are thin and flexible, enabling designers to create thinner and lighter speaker systems.

Its compact shape allows for portable design and efficient use of space.

Q: How does PI Multilayer FPCs enhance signal transmission in loudspeakers?

A: PI Multilayer FPCs have low impedance and signal loss characteristics, ensuring efficient signal transmission within the speaker system. This results in improved audio quality and fidelity.

Q: Can PI Multilayer FPC be used for unconventional loudspeaker designs?

A: Yes, PI multilayer FPCs can be used for unconventional loudspeaker designs. Their flexibility allows integration into various form factors, enabling the creation of unique and innovative loudspeaker shapes.

Q: How does PI multilayer FPC improve the durability and reliability of speakers?

A: PI multilayer FPC is highly resistant to temperature changes, moisture and mechanical stress, making it more durable and reliable under challenging operating conditions. They can withstand harsh environments without compromising performance.

Q: What are the benefits of using PI multilayer FPC for speaker integration?

A: PI multilayer FPC allows multiple electronic components and circuits to be integrated into one flexible board, which simplifies the speaker assembly and integration process. This reduces manufacturing costs and increases overall efficiency.

Q: How does the PI multilayer FPC support the high frequency performance of the speaker?

A: PI multilayer FPC has the ability to support high-frequency signals, enabling speakers to accurately reproduce a wider range of audio frequencies. They minimize signal loss and impedance, improving sound quality and clarity, especially for high-resolution audio formats.