4 layer Flex PCB Thick Gold Circuit Board Supplier Quick Turn FR4 PCB Prototype

How Capel's 4 Layer Flex PCB Thick Gold Circuit Board Supplier Quick Turn FR4 PCB Prototype Provides Reliability Solutions for Our Customers

-Capel with 15 years of professional technical experience-

Product Features: Unprecedented precision and durability

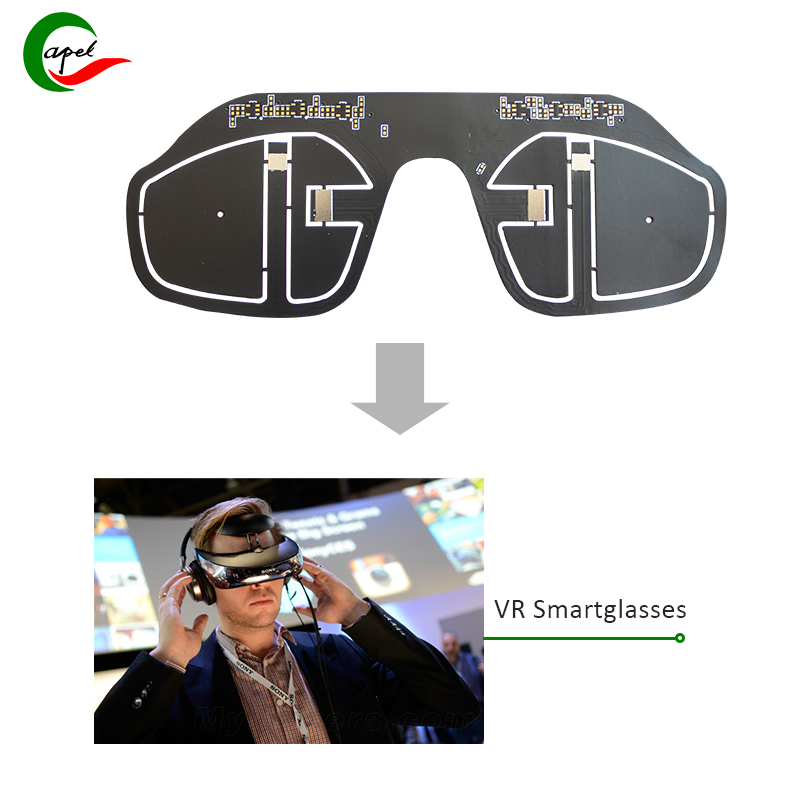

For VR smart glasses, precision and durability are crucial. The 4-layer flexible PCB excels in both aspects, ensuring a superior VR experience. Let’s take a closer look at its unique product features:

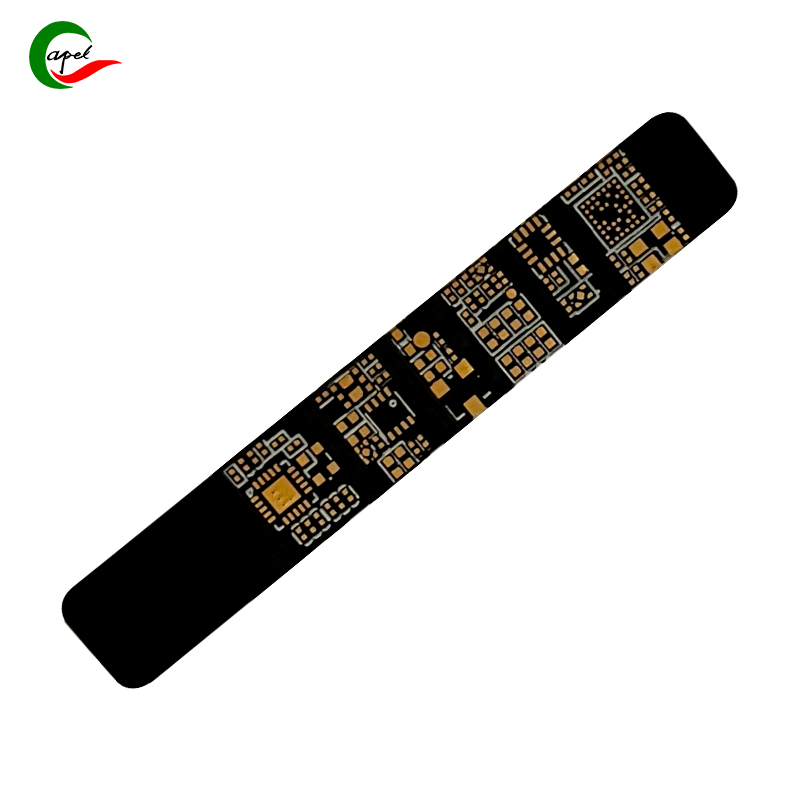

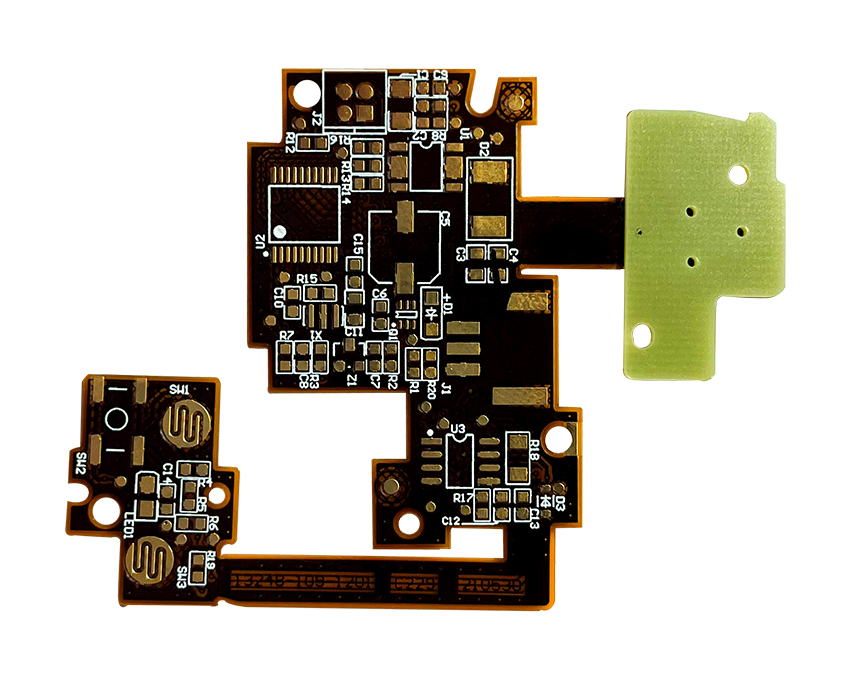

1. Product type: 4-layer flexible PCB circuit board

The 4-layer flexible PCB circuit board is specially designed to meet the demanding requirements of VR smart glasses. With advanced manufacturing techniques and meticulous attention to detail, these boards consistently deliver outstanding electrical performance.

2. Line width and line spacing: 0.05mm/0.05mm

The line width and line spacing accuracy of 4-layer flex PCB is unparalleled. With widths and spacing as small as 0.05mm, these boards provide superior signal integrity, minimizing interference and delivering a clear VR experience.

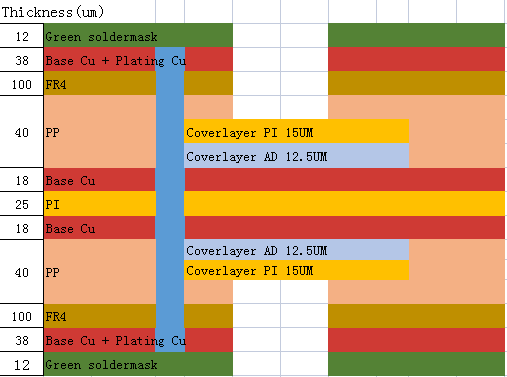

3. Plate thickness: 0.2mm

A slim profile is crucial for VR smart glasses. The 4-layer flexible PCB's ultra-thin board thickness is only 0.2 mm, allowing for a compact, lightweight design without compromising performance.

4. Minimum aperture: 0.1mm

The 4-layer flexible PCB has a minimum aperture size of 0.1 mm, ensuring precise placement of components, thereby enhancing the overall functionality and reliability of the VR smart glasses.

5. Copper thickness: 12um

Excellent electrical conductivity is crucial for data transmission in VR devices. The 4-layer flexible PCB has a copper thickness of 12um, which provides optimal signal transmission and ensures seamless interaction between the user and the virtual world.

6. Flame retardant: 94V0

When designing electronic devices, safety is paramount. The 4-layer flexible PCB has a high level of flame retardancy and meets the strict 94V0 standard, ensuring the safety and reliability of VR smart glasses.

7. Surface treatment: immersion gold

The surface treatment of the PCB plays a vital role in ensuring a reliable connection. The 4-layer flex PCB features immersion gold, a highly effective surface treatment that enhances solderability and prevents oxidation, improving performance and longevity.

8. Resistance welding color: black

With its stylish black color, the 4-layer Flex PCB blends seamlessly with the overall aesthetics of the VR smart glasses, enhancing its visual appeal.

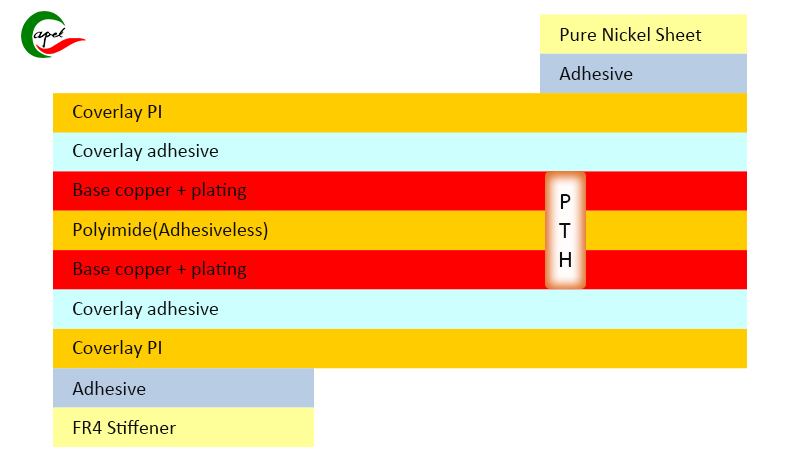

9. Stiffness: steel shell, FR4

4-layer flexible PCB provides the perfect balance between flexibility and rigidity. It uses a steel shell and FR4 material to provide the necessary rigidity to support the numerous components while maintaining the flexibility required for VR smart glasses.

10. Application: VR smart glasses

The application of 4-layer flexible PCB in VR smart glasses is transformative. These PCBs enable seamless integration of various components to deliver immersive and engaging VR experiences to users around the world.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

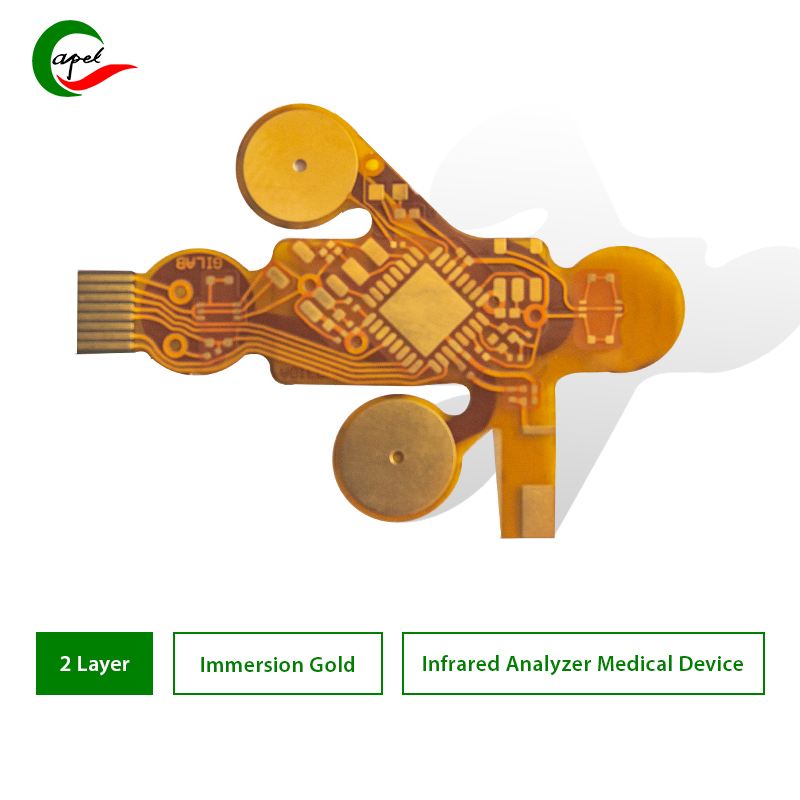

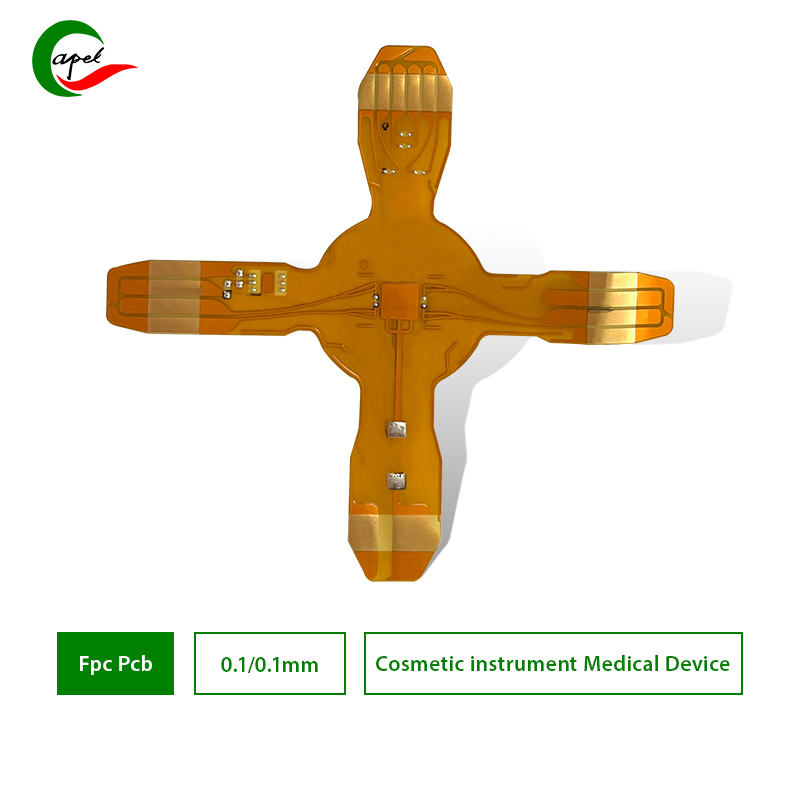

2 Layers Double-sided Fpc Pcb

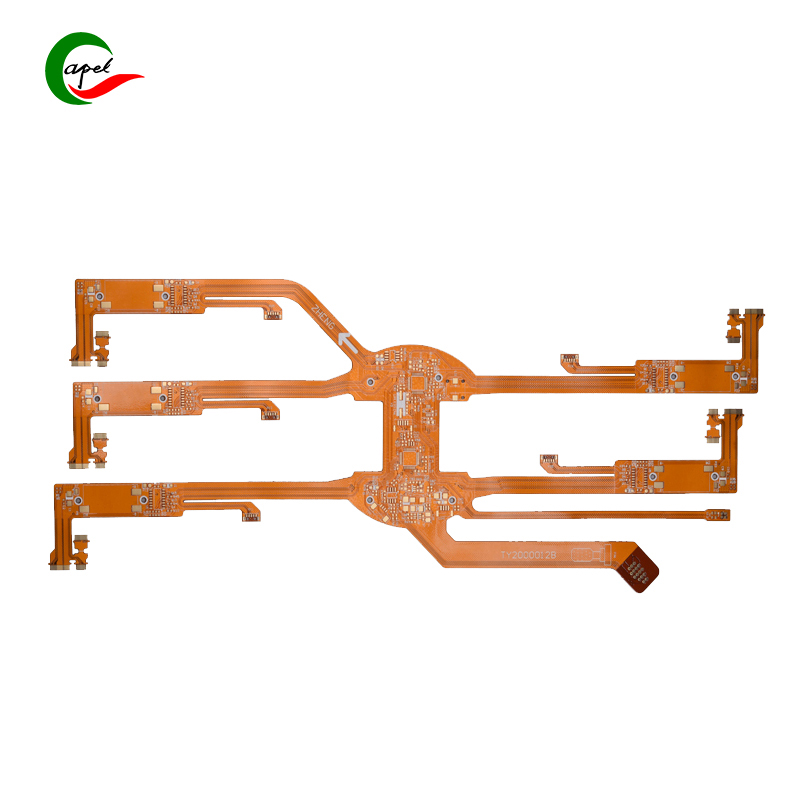

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.