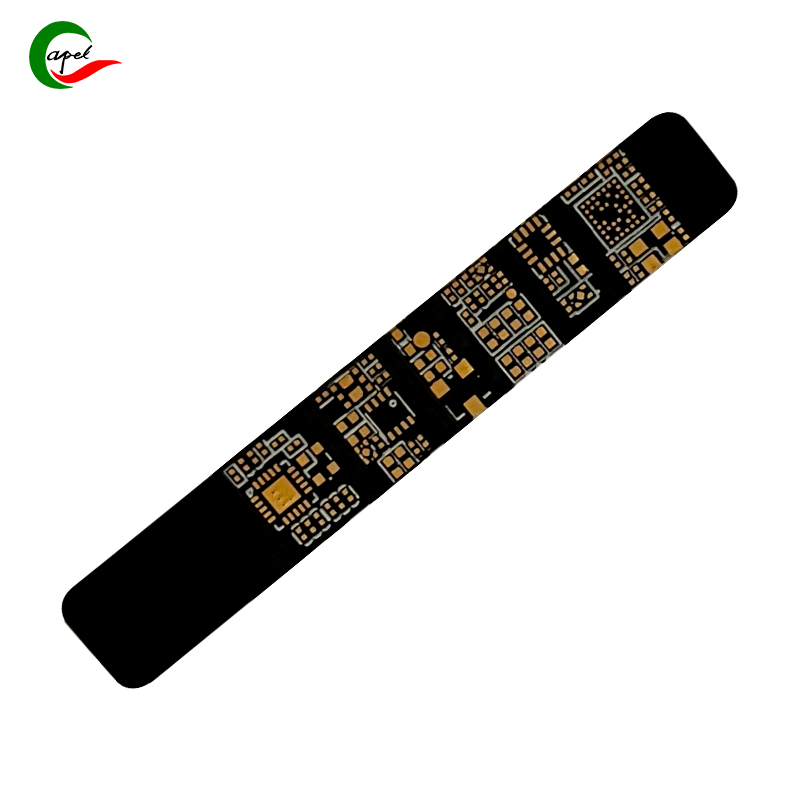

4 layer Flex PCB boards Stiffness Steel Sheet Copper Thickness 12um 94V0

How Capel's 4 Layer Flex PCB Boards Stiffness Steel Sheet Copper Thickness 12um 94V0 Provides Reliability Solutions for New Energy Automakers

-Capel with 15 years of professional technical experience-

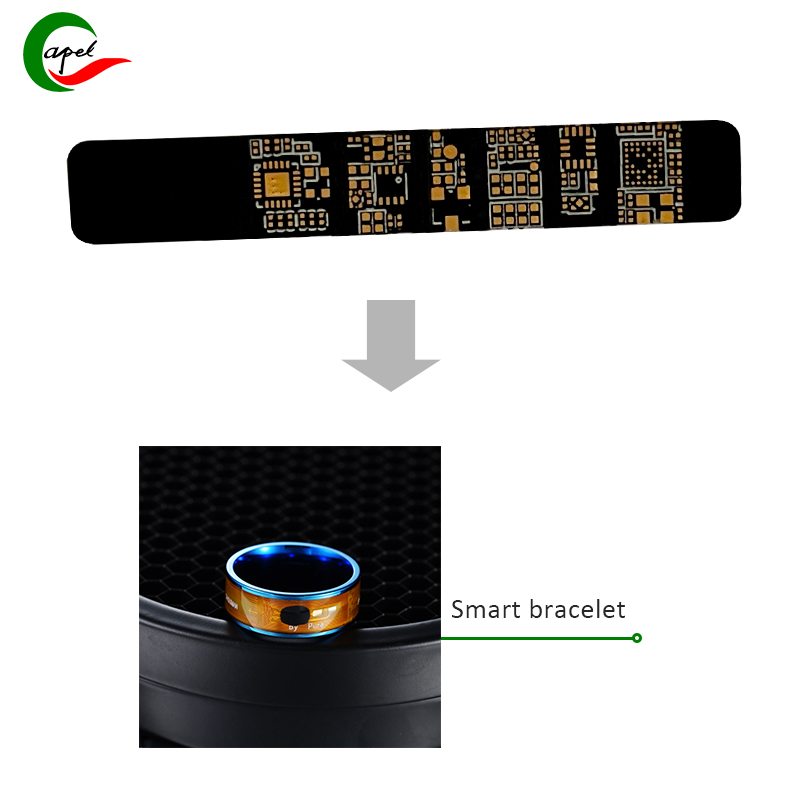

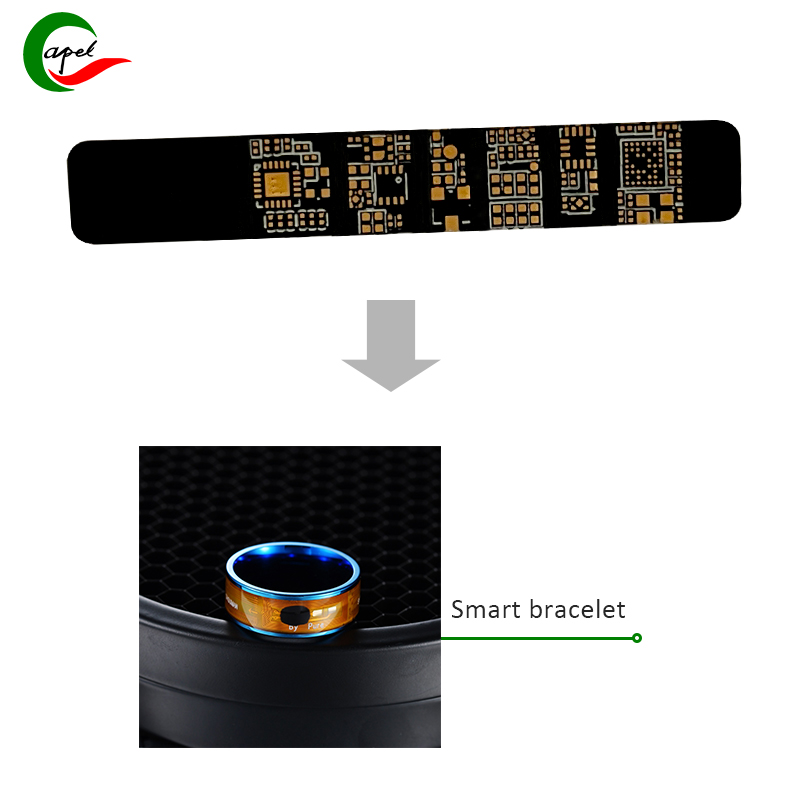

In the manufacturing of smart bracelets, the quality of the printed circuit boards used plays a vital role. 4-layer flexible PCB boards are preferred by manufacturers as they offer several advantages that make them ideal for this application. Let’s take a closer look at these boards and why they are the top choice for smart bracelets.

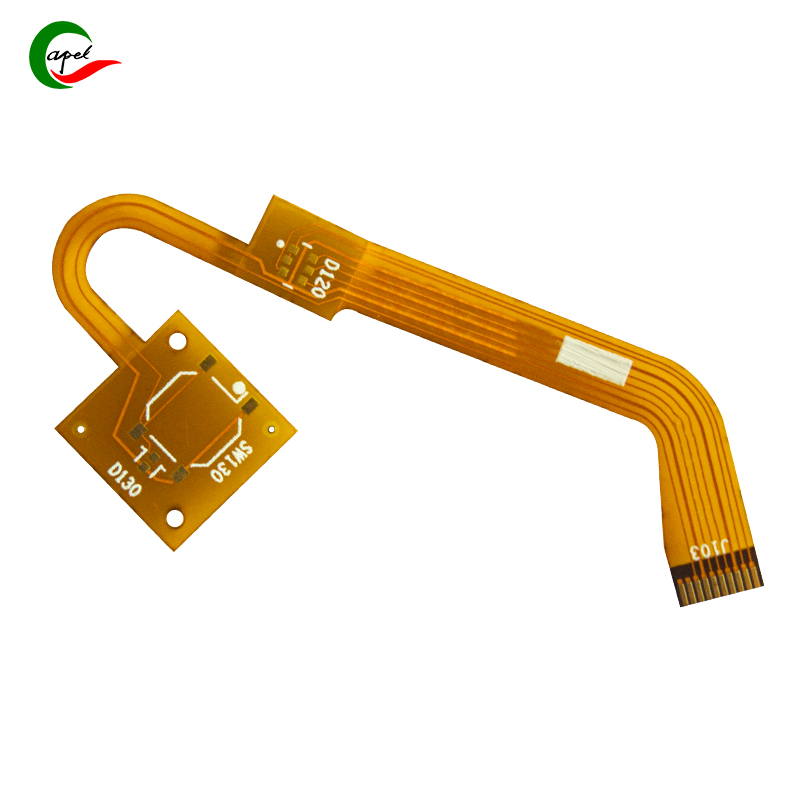

First, let’s talk about the product type: 4-layer flexible printed circuit board. The plates are specifically designed to be flexible and can bend and conform to the shape of the smartband. The flexibility of these plates is crucial as it ensures that the device is comfortable to wear and does not restrict movement.

In terms of technical specifications, these motherboards are no slouch either. Their line width and line spacing are 0.06mm/0.06mm, providing excellent precision and accuracy. This means the signals and data transmitted within the smartband are clear and reliable, ensuring smooth and uninterrupted performance.

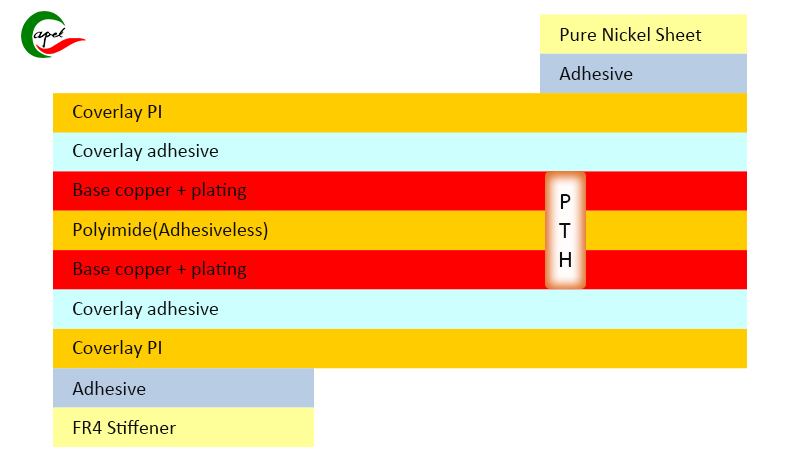

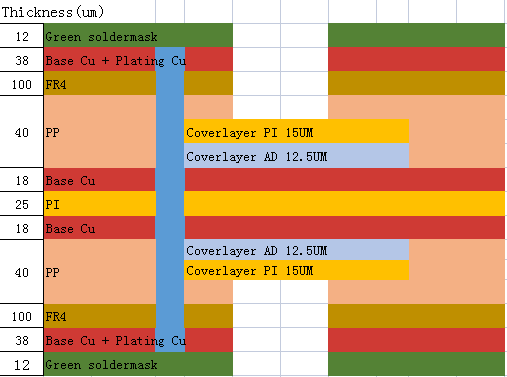

Another important factor to consider is the thickness of the board. For a 4-layer Flex PCB board, the thickness is set to 0.2mm. This thickness provides the perfect balance between durability and flexibility, ensuring the board can withstand the wear and tear of daily use while still being flexible enough to be bent and formed.

Moving on to the minimum hole diameter, these plates have a minimum hole diameter of 0.15 mm. This specification is critical because it determines the size of vias and holes on the board. The smaller aperture allows for a more precise and compact design, ensuring the smart band remains stylish and beautiful.

Copper thickness is another important consideration in the manufacturing process. The copper thickness of the 4-layer flexible PCB board used in smart bracelets is usually 12um. This thickness is ideal for providing adequate conductivity while keeping the overall weight of the device to a minimum.

One of the key factors to consider when manufacturing any electronic device is safety. Smart bracelets are no exception. That's why these boards are manufactured using flame-retardant materials with class 94V0. This rating ensures that the circuit board is flame-resistant and will not cause a fire to spread in an emergency.

Surface treatment is another important aspect of the manufacturing process. For the 4-layer Flex PCB boards used in smart bracelets, immersion gold is the preferred surface treatment. This treatment not only enhances the circuit board's electrical conductivity, but also provides superior corrosion resistance, ensuring the longevity of the device.

When it comes to the aesthetics of your smart bracelet, resistance welding color plays an important role. Most manufacturers choose black as it adds a touch of elegance and sophistication to the overall design.

Finally, let's talk about stiffness and applications. The 4-layer flexible PCB board used in the smart bracelet is designed to have the stiffness of a steel plate. This stiffness ensures that the device retains its shape and form even after prolonged use.

As for applications, these boards are specifically for smart bracelets. As the demand for wearable technology continues to grow, smart bracelets have gained immense popularity. These devices offer a wide range of features, including activity tracking, heart rate monitoring, sleep tracking, and more. They are designed to fit seamlessly into your daily life to help you achieve your health and fitness goals.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Rigid Flexible Circuit Board with 15 years of experience with our professionalism

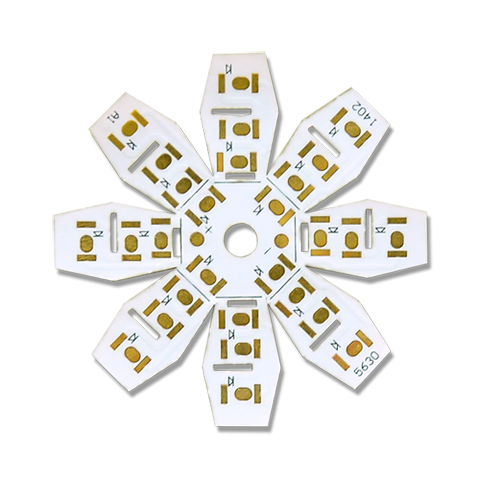

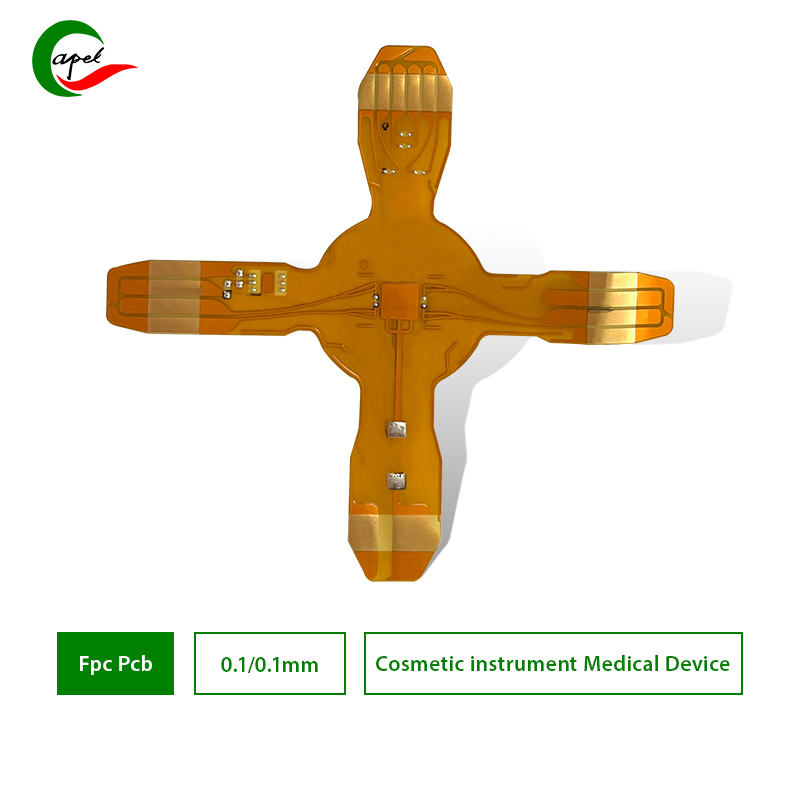

2 Layers Double-sided Fpc Pcb

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.