2 layer Flexible Printed Circuit Online Pcb Manufacturer SMT Assembly Services

How Capel's 2 Layer Flexible Printed Circuit Online Pcb Manufacturer SMT Assembly Services Provides Reliability Solutions for Our Customers

-Capel with 15 years of professional technical experience-

2-Layer Flexible Printed Circuits: A Revolution in Communications Electronics

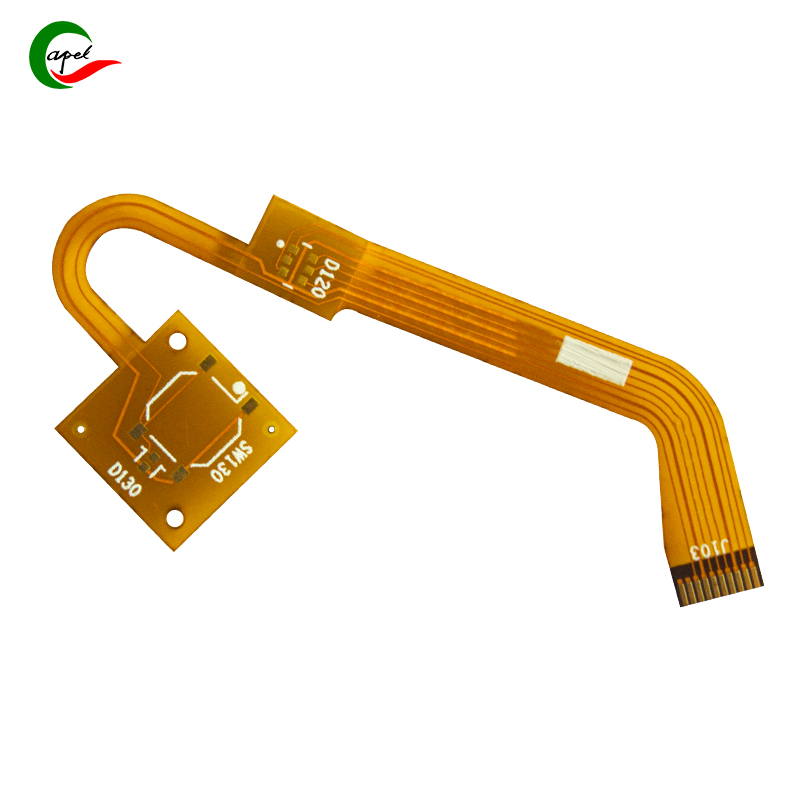

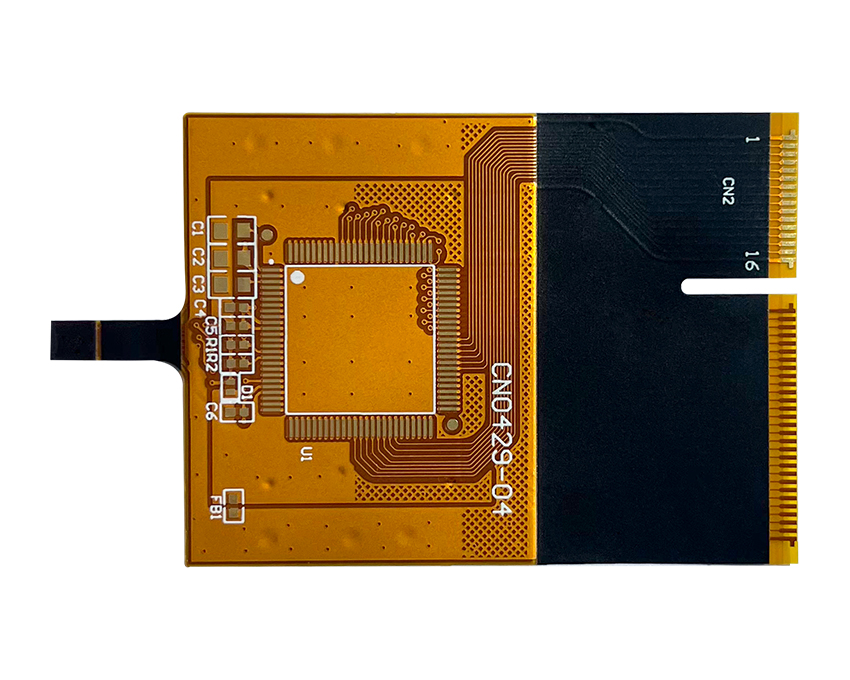

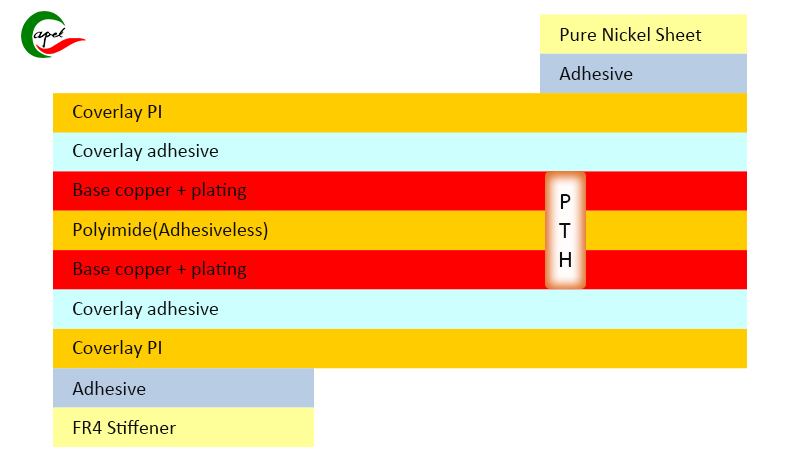

A 2-layer flexible printed circuit refers to a circuit board that consists of two layers of copper conductive material separated by a flexible insulating material. This compact design improves signal transmission and reduces electromagnetic interference. By applying this technology to communications electronics, manufacturers can significantly improve device performance, making it more reliable and efficient.

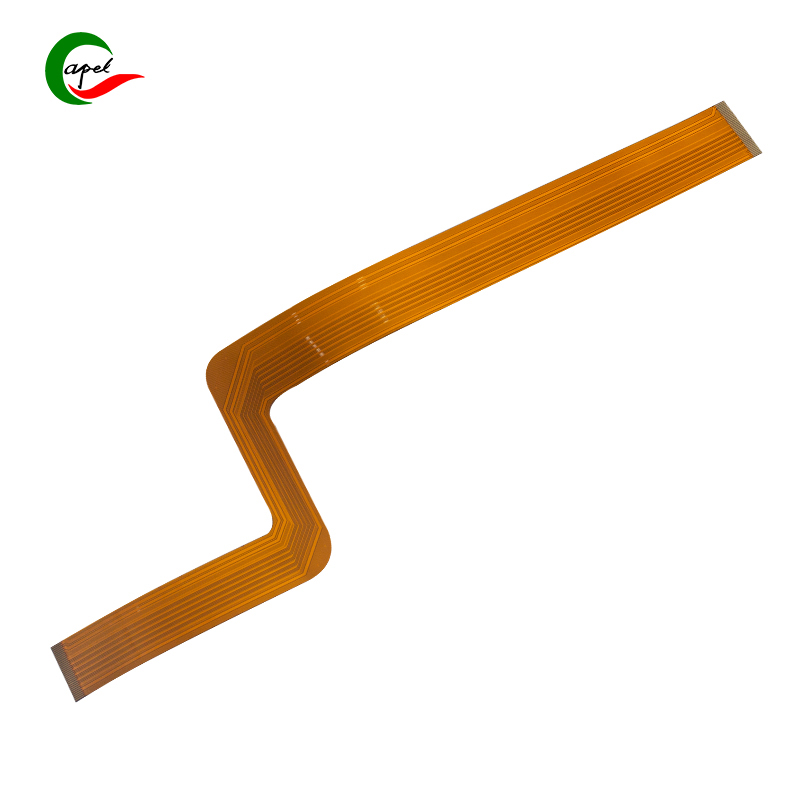

One of the main features of 2-layer flexible printed circuits is their impressive line widths and spacing. These circuits feature 0.05mm/0.05mm line width and spacing, allowing for precise connections between components. This level of precision ensures smooth transmission of electrical signals, minimizing signal loss and improving overall device performance. Whether transmitting data or facilitating voice communications, the precision provided by these FPCs greatly enhances the capabilities of communications electronics.

Circuit board thickness is another critical factor in the design and performance of communications electronics. The 2-layer flexible printed circuit board is 0.1 mm thick, providing the perfect balance between flexibility and durability. This low-profile form factor allows for easy integration into compact devices while still providing the necessary strength to withstand regular use and handling. The reduced thickness also helps reduce the overall weight of communications devices, making them more portable and user-friendly.

When it comes to connections, the minimum aperture of the circuit is critical. The 2-layer flexible printed circuit has a minimum aperture size of 0.1 mm, allowing for seamless connections between various components. This precision ensures optimal electrical conductivity without the risk of short circuits or signal interference. By enabling reliable connectivity, these FPCs enhance the overall performance and stability of communication electronics.

Copper thickness is another important aspect of 2-layer flexible printed circuits. The copper thickness of these circuits is 12um for excellent conductivity and heat dissipation. High-quality copper materials ensure reliable electrical connections and effectively manage the heat generated during device operation. This feature is particularly important in communications electronics, where efficient heat dissipation is critical to prevent overheating and maintain optimal device performance.

When it comes to electronic devices, safety is paramount, and the flame-retardant properties of 2-layer flexible printed circuits ensure peace of mind for both manufacturers and consumers. These circuits have a flame retardant rating of 94V0, providing excellent flame retardancy and preventing the spread of fire. This feature adds an extra layer of protection to communications electronics, reducing fire hazards and ensuring equipment safety in a variety of environments.

Surface treatment is another key aspect of 2-layer flexible printed circuits. Immersion gold surface treatment has become a popular choice for communication electronics due to its excellent conductivity and corrosion resistance. This treatment ensures reliable signal transmission and prevents the copper conductive material from oxidizing or tarnishing. By implementing an immersion gold surface treatment, manufacturers can guarantee the long-term performance and durability of communications electronics.

Resistance welding color may seem like a small detail, but it plays an important role in equipment aesthetics and identification. 2 layer flex printed circuits usually have a yellow resistance soldering color. This color not only increases the visual appeal of communications electronics, but also helps identify and distinguish different circuits and components during the manufacturing process. Attention to detail in resistance welding color reflects a commitment to quality and precision in the production of communications electronics.

While flexibility is a defining characteristic of 2-layer flexible printed circuits, it must be emphasized that rigidity is also a valuable characteristic. FR4 is a fiberglass reinforced material that provides the necessary rigidity to support components and ensure stability. By combining flexibility with stiffness, these FPCs provide the perfect balance for communications electronics, allowing seamless integration into devices without compromising reliability or performance.

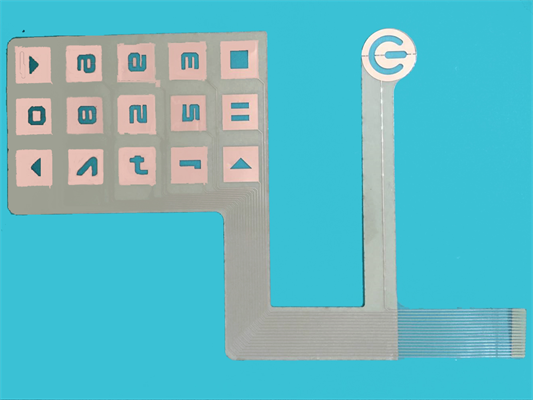

The innovation doesn't stop with the features mentioned above. In terms of special processes, 2-layer flexible printed circuits offer endless possibilities for customization and optimization. Manufacturers can customize their FPC designs to meet the specific requirements and functionality of communications electronics. This flexibility allows for the creation of unique devices that meet niche market or specific user needs.

2-layer flexible printed circuits are widely used in the field of communication electronics. These circuits are key components in smartphones, tablets, wearables, and a variety of other wireless communications devices. Their compact design, enhanced performance and reliable connectivity make them ideal for these applications. From transmitting high-speed data to facilitating seamless voice communications, these FPCs help ensure the smooth operation of communications electronics.

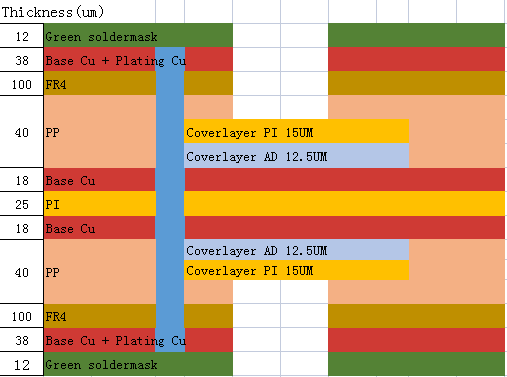

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

2 Layers Double-sided Fpc Pcb

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.