14 layer Rigid Flex Pcb Fabrication manufacturer Quick Turn Prototype

How Capel's 14 Layer Rigid Flex Pcb Fabrication Manufacturer Quick Turn Prototype Provides Reliability Solutions for Our Customes

-Capel with 15 years of professional technical experience-

At Shenzhen Capel Technology Co., Ltd., we specialize in providing best-in-class PCB manufacturing services, including 14-layer rigid-flex PCB manufacturing. With years of industry experience and commitment to innovation, we have become a leading manufacturer in the market. Our rapid turnaround prototyping capabilities allow us to provide fast and efficient solutions, ensuring your project is completed on time without compromising on quality.

Why choose 14-layer soft-hard composite board?

14-layer rigid-flex PCBs offer several advantages, making them a popular choice for a variety of applications. Here are the reasons why you should consider using this advanced technology in your electronic devices:

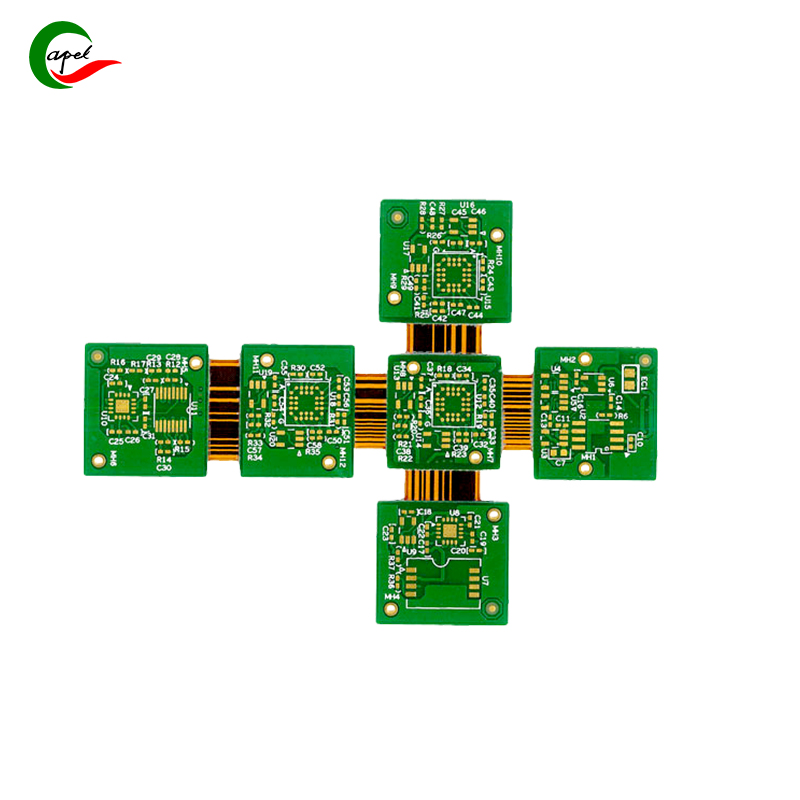

1. Space optimization: The combination of rigid and flexible layers allows designers to maximize space utilization within a compact form factor. This is particularly important in industries where size and weight constraints are critical, such as the aerospace, medical and defense sectors.

2. Reliability and durability: The multi-layer structure enhances structural integrity and stability, making the 14-layer rigid-flex PCB highly resistant to mechanical stress, vibration and temperature fluctuations. This makes them ideal for applications requiring long-term reliability and durability.

3. Increased circuit complexity: The numerous layers in a 14-layer rigid-flex PCB provide ample space for complex circuit designs. This enables engineers to integrate more components, enabling advanced functionality and enhanced performance in electronic devices.

4. Cost-Effectiveness: Despite its complexity and advanced features, 14-layer rigid-flex PCB remains cost-effective compared to alternative solutions. Reduced number of interconnecting cables and connectors means lower assembly and maintenance costs.

Work with a trusted manufacturer

For critical components such as PCBs, choosing a manufacturer you can trust is crucial. At Shenzhen Capel Technology Co., Ltd., we prioritize customer satisfaction and strive to exceed expectations on every project. Our commitment to quality and innovation is reflected in our state-of-the-art manufacturing facilities, staffed with cutting-edge technology and a team of highly-skilled experts.

We know time is of the essence, especially when prototyping quickly. With our streamlined processes and efficient production cycles, we can quickly deliver high-quality 14-layer rigid-flex PCBs to ensure your project progresses smoothly and stays on schedule. We also maintain open lines of communication throughout the manufacturing process to keep you informed and updated on the status of your prototype.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

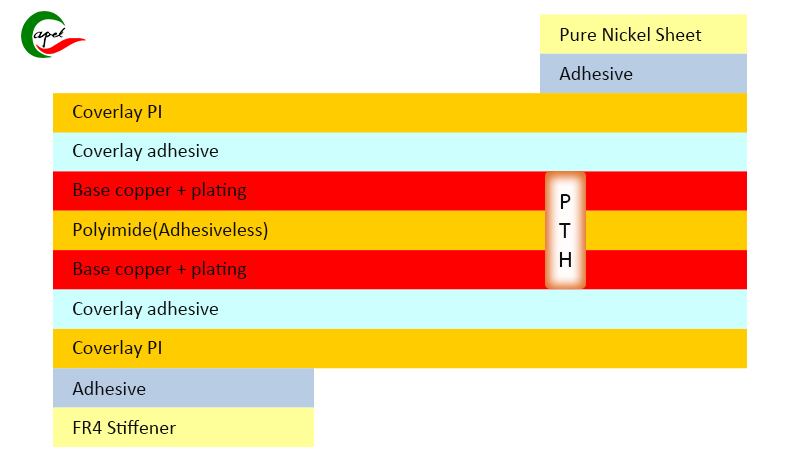

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

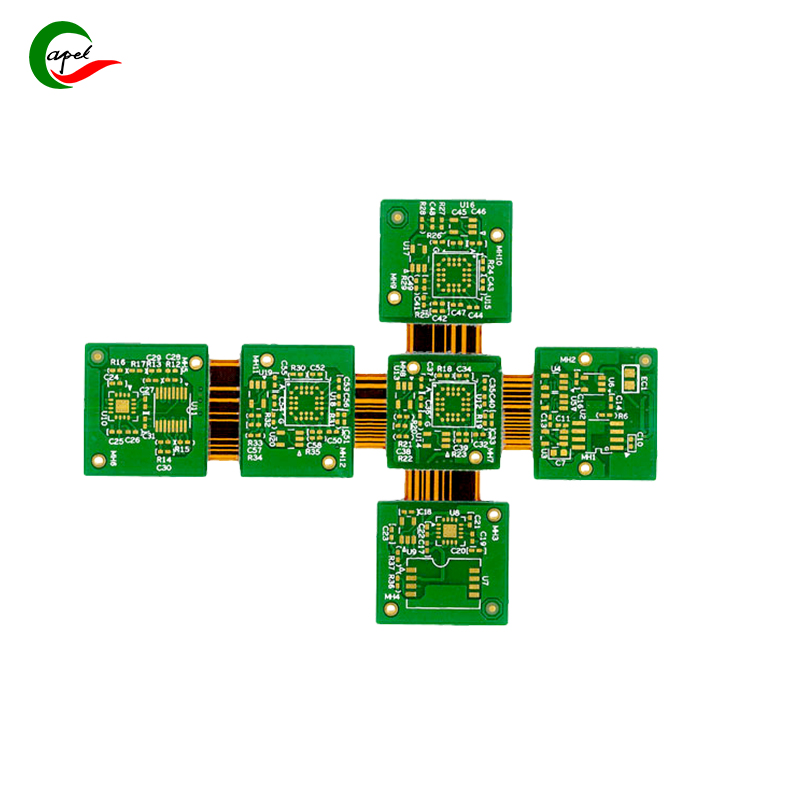

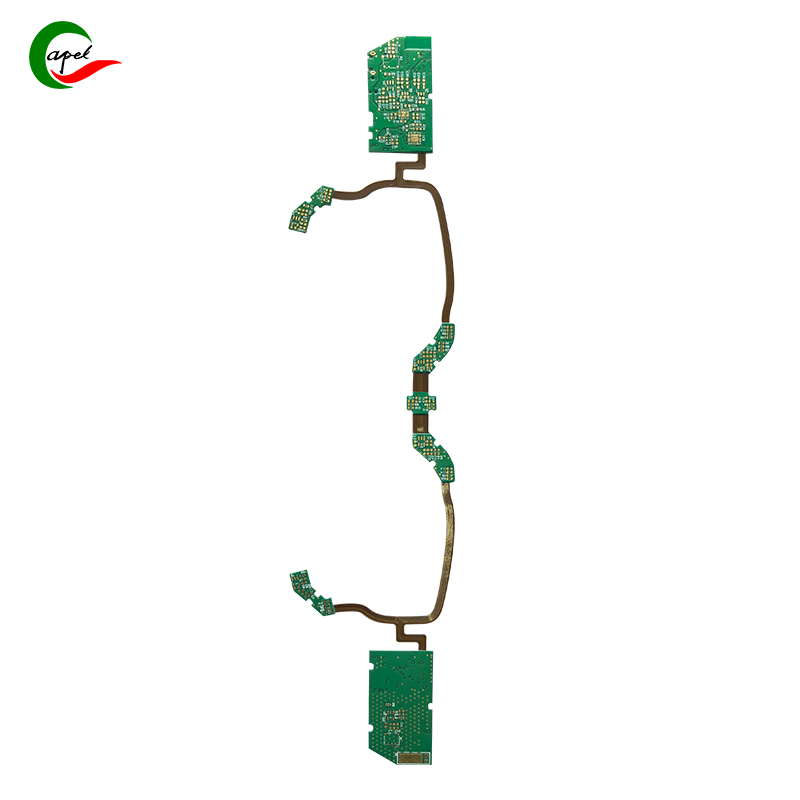

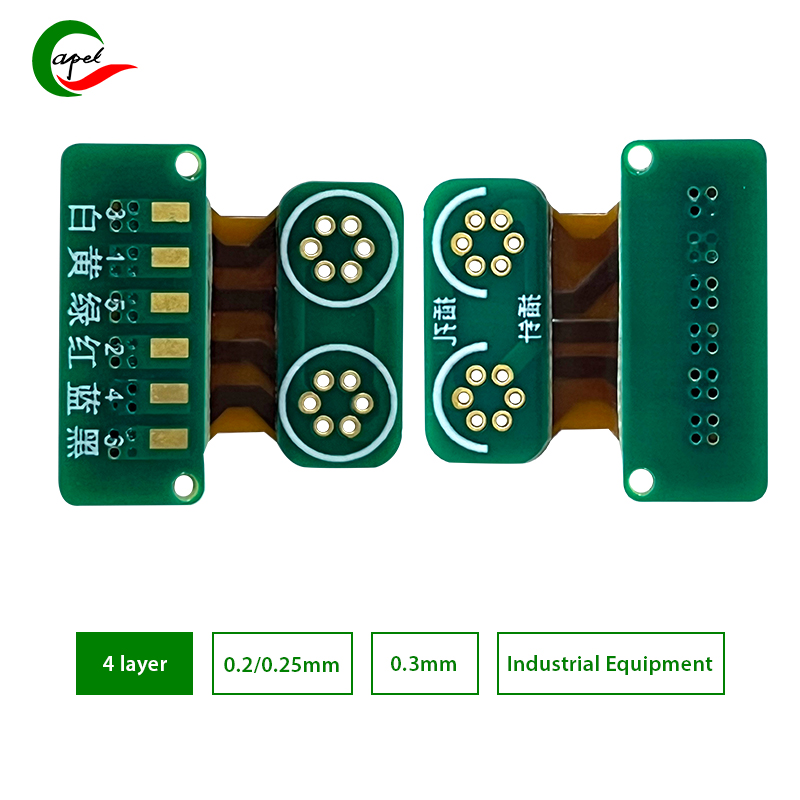

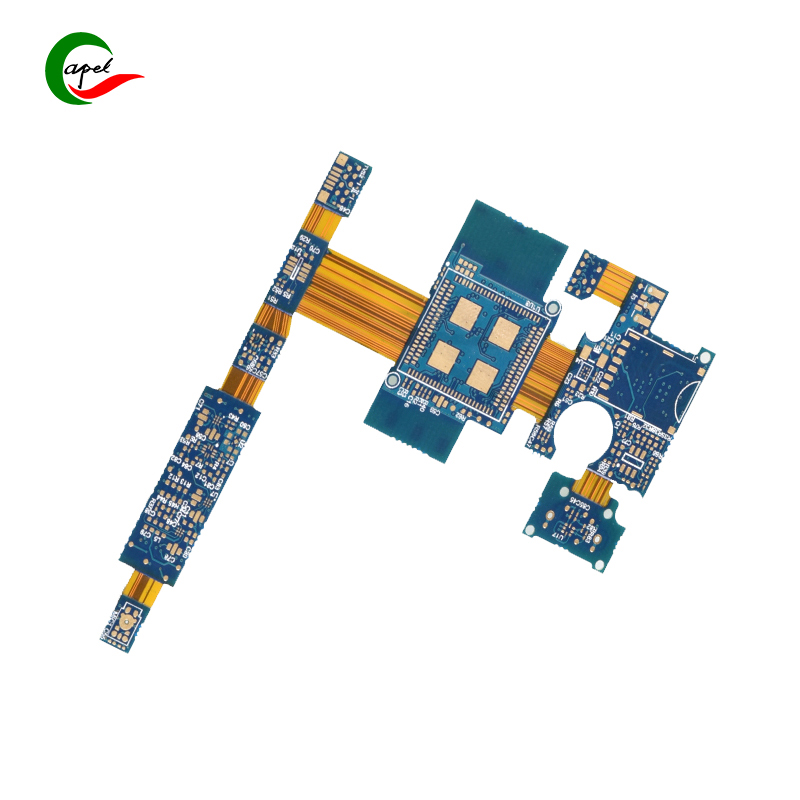

Capel do customize Rigid Flexible Printed Circuit Boards with 15 years of experience with our professionalism

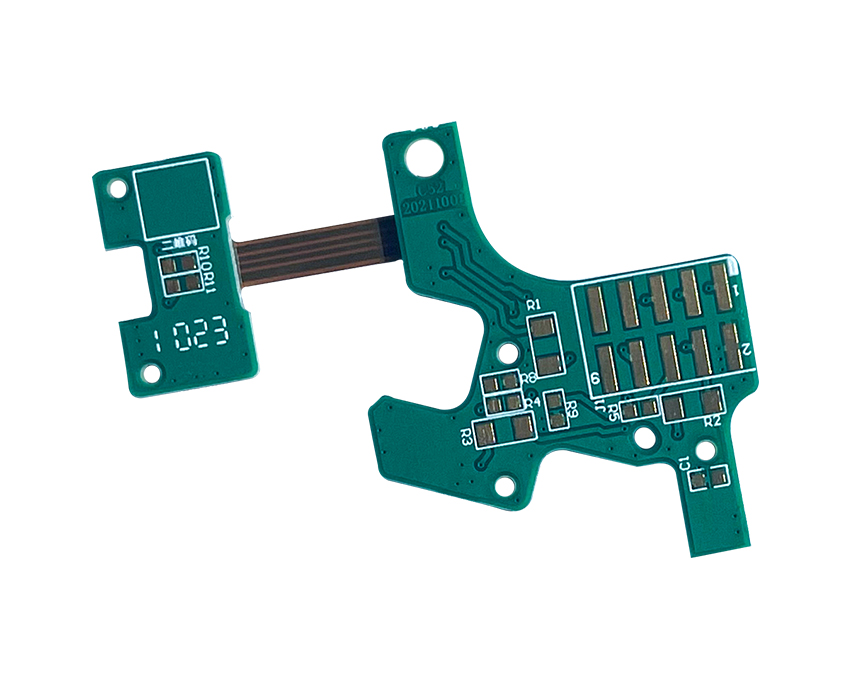

2 Layers Double-sided Fpc Pcb

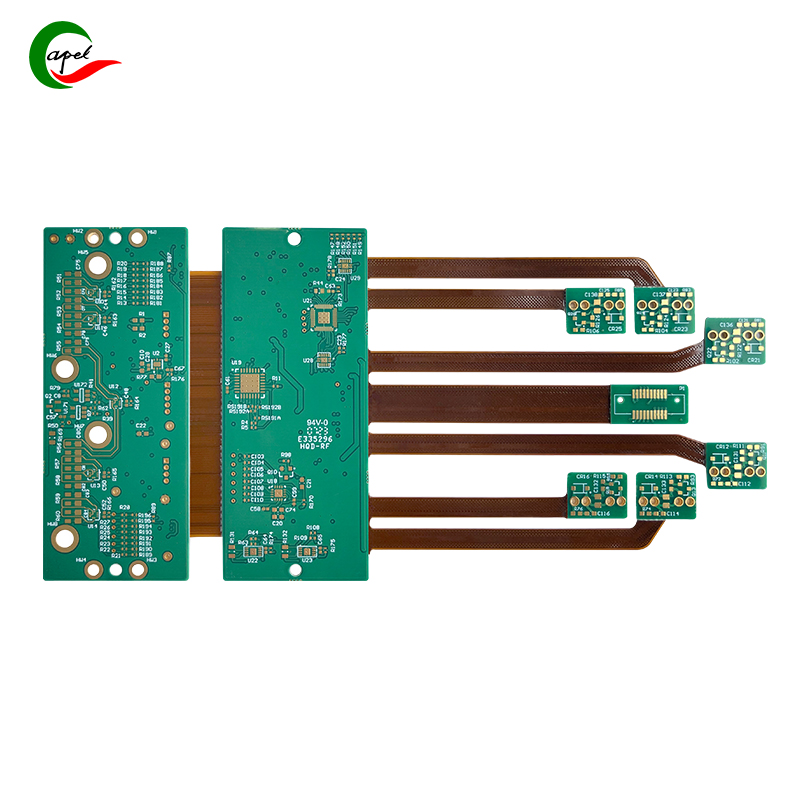

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.