12 layer Rigid Flexible Circuit Boards HDI Blind Hole PCB Immersion Gold

How Capel's 12 Layer Rigid Flexible Circuit Boards HDI Blind Hole PCB Immersion Gold

Provides Reliability Solutions for Our Customers

-Capel with 15 years of professional technical experience-

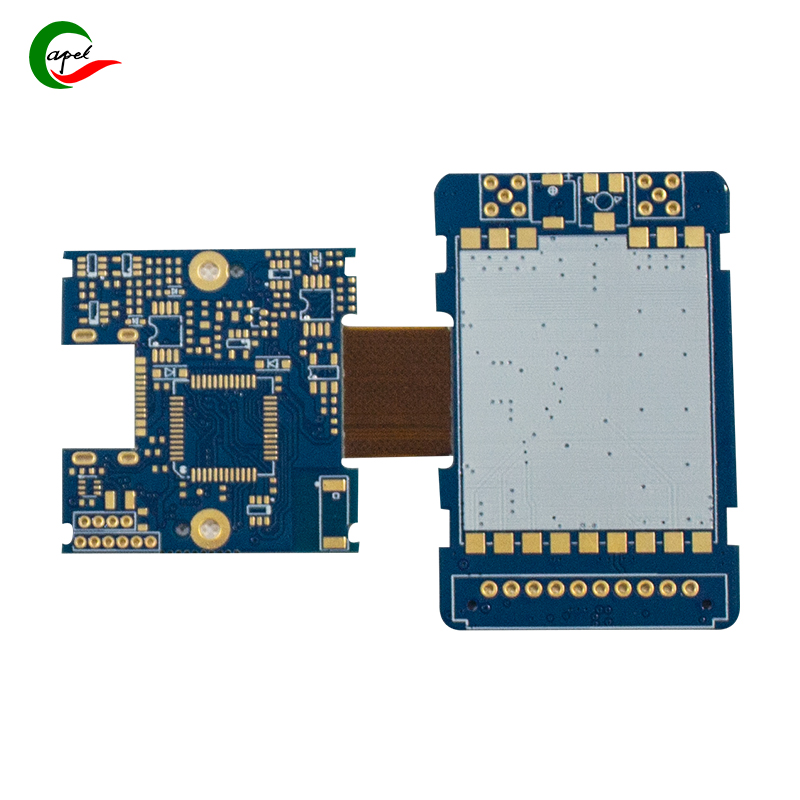

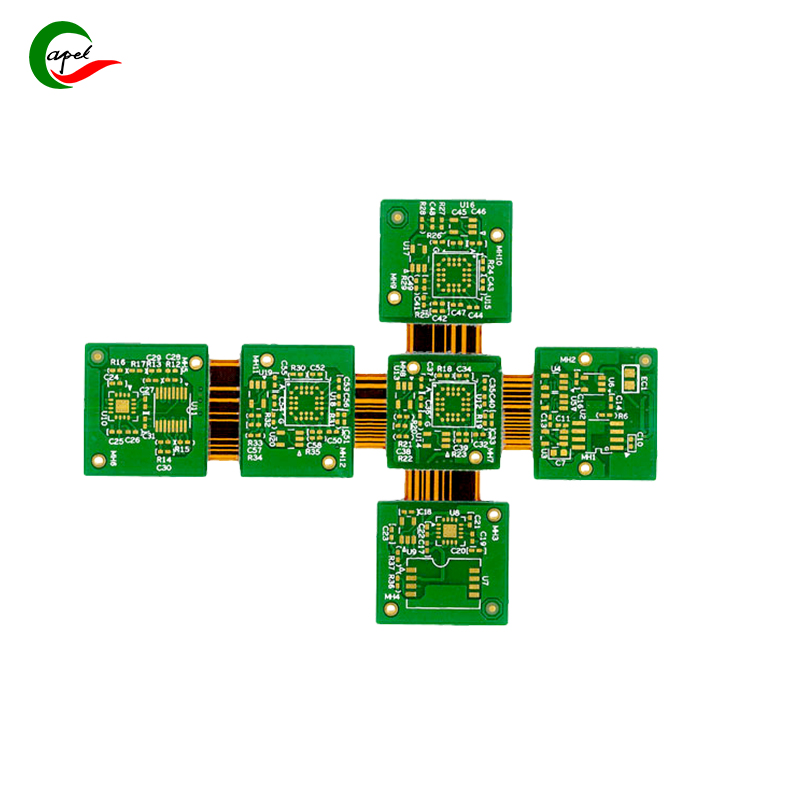

When talking about advanced circuit boards, one cannot ignore the numerous advantages offered by 12-layer rigid-flex circuit boards. These cutting-edge boards feature high-density interconnect (HDI) blind vias and an immersed gold finish, making them ideal for a variety of applications.

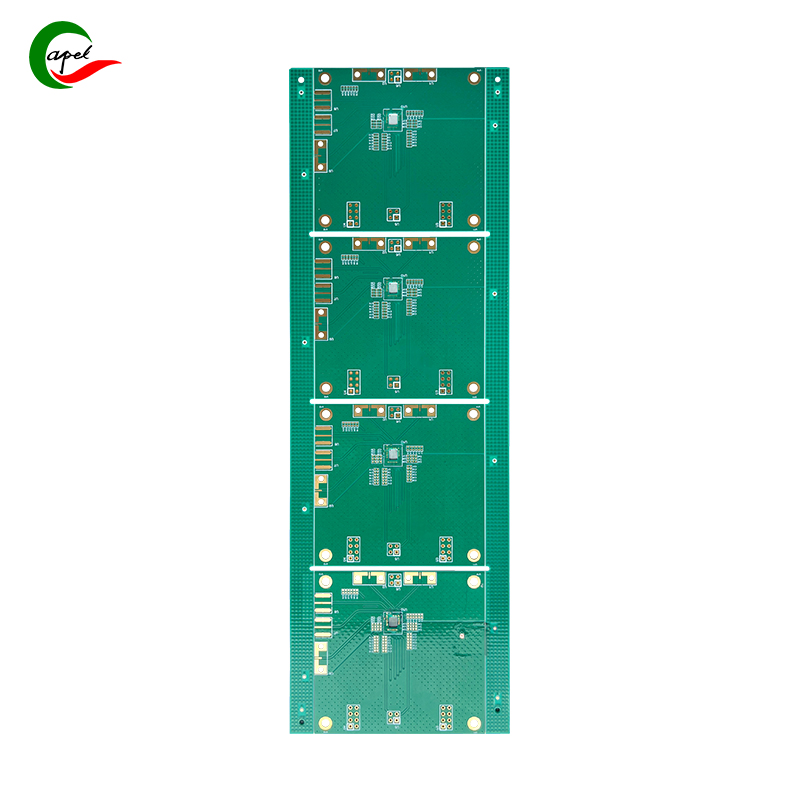

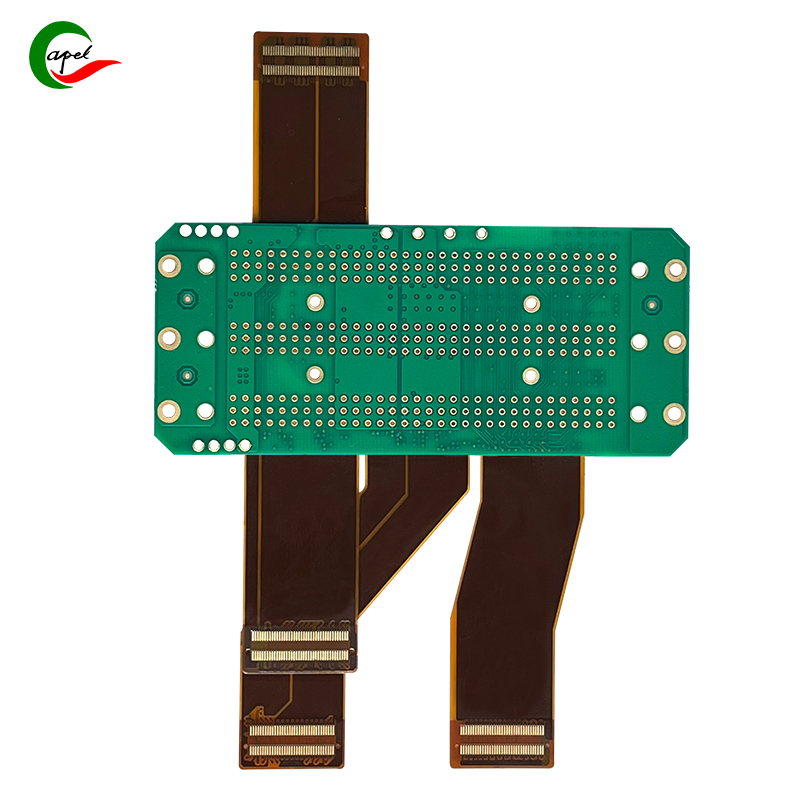

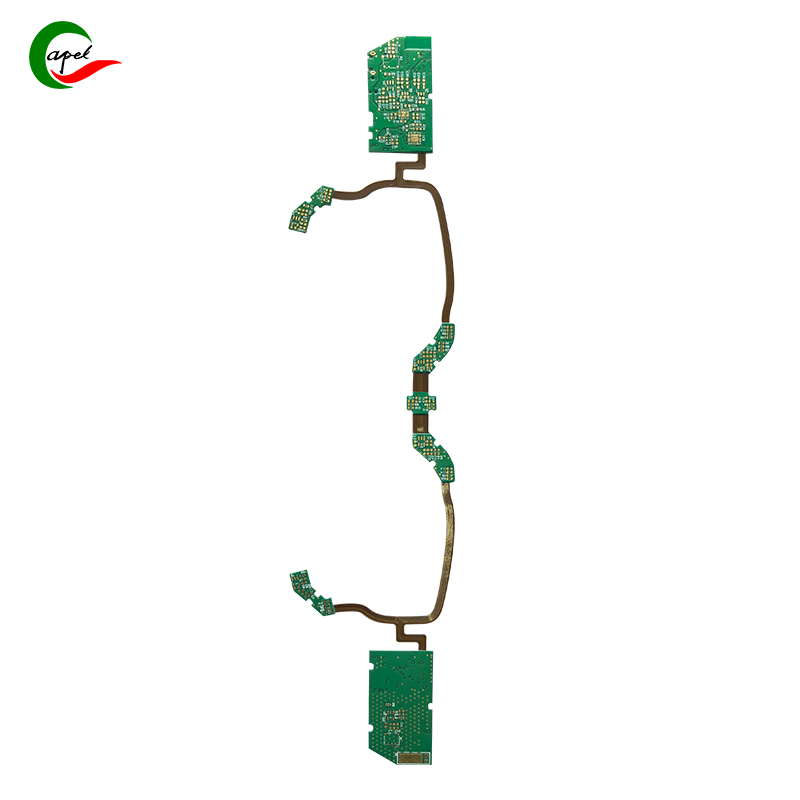

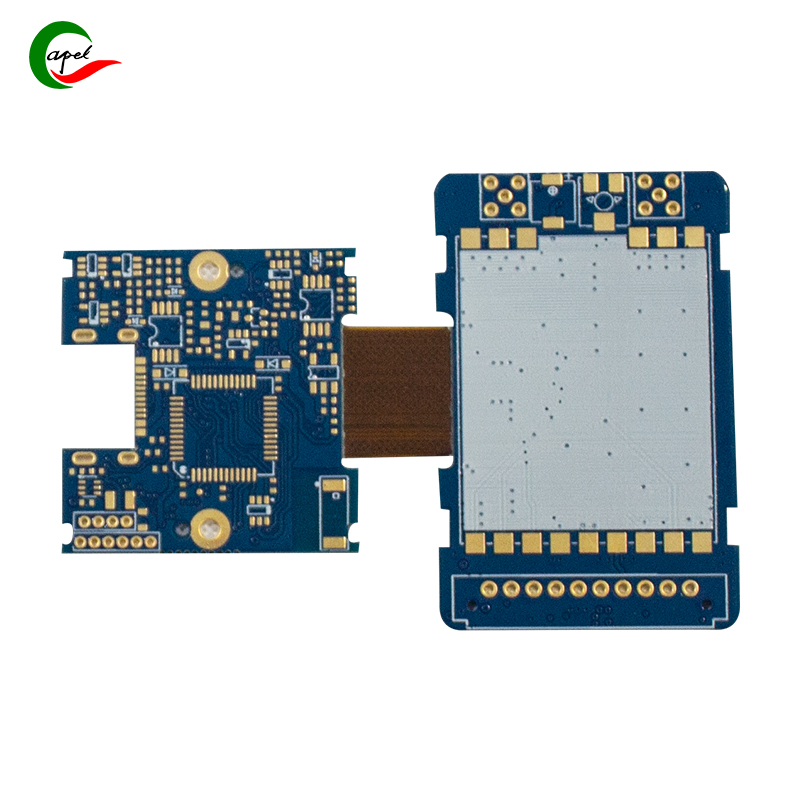

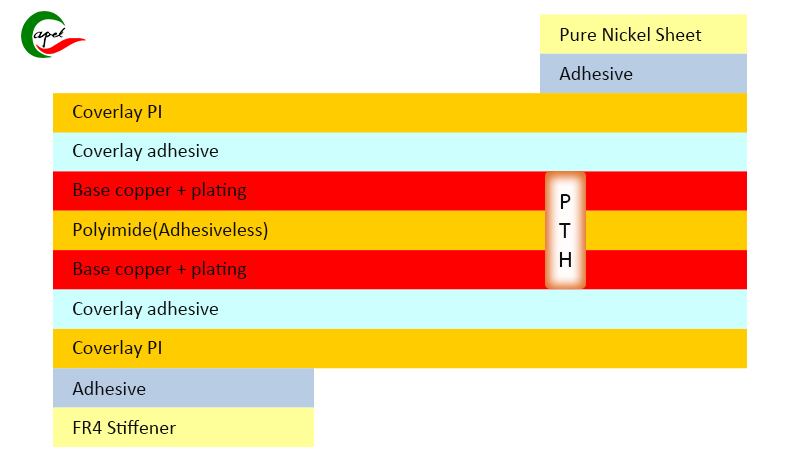

The 12-layer rigid-flex circuit board adopts a high-efficiency stacked design, has excellent flexibility, and is suitable for complex electronic devices. The combination of rigid and flexible layers allows for optimal integration and space utilization, ensuring these boards can meet the demanding requirements of modern electronics.

One of the main advantages of 12-layer rigid-flex circuit boards is the ability to accommodate blind vias. Blind vias are integral components that connect different layers of a circuit board. Through blind vias, electrical connections can be routed from the inner layer to the outer layer, optimizing the overall performance and functionality of the board.

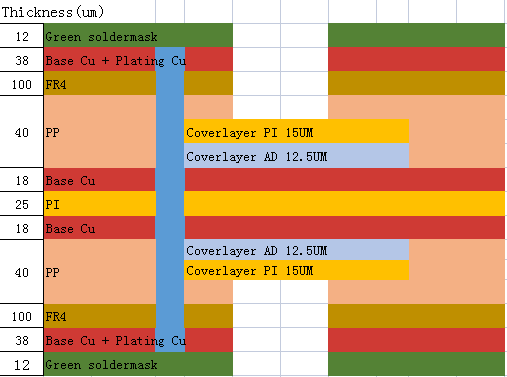

These boards are manufactured using state-of-the-art technology and industry-leading equipment. The line width and line spacing are designed with an accuracy of 0.1mm/0.1mm, ensuring high signal integrity and minimizing the risk of signal interference. The board thickness is maintained at 1.6mm, achieving a perfect balance between flexibility and durability.

To ensure the highest level of quality, the 12-layer rigid-flex circuit board undergoes a special process called immersion gold surface treatment. This treatment not only enhances the overall appearance of the board, but also provides superior protection against oxidation and corrosion. The immersion gold surface treatment adds a layer of reliability to the circuit board, ensuring longevity and stable performance.

Additionally, these boards are available in different copper thickness options, including 18um and 35um. The copper thickness determines the current carrying capacity and heat dissipation capacity of the board. By offering multiple copper thickness options, manufacturers provide customers with the flexibility to choose the most appropriate option for their specific application.

The 12-layer rigid flex circuit board goes through a special process called high-density interconnect (HDI). HDI helps optimize the routing capabilities of these boards, resulting in increased circuit density and improved signal transmission. This special process ensures that these boards meet the demanding requirements of high-performance applications.

In addition to their technical advantages, these boards are also environmentally friendly. They are manufactured from materials that do not contain harmful substances and comply with international environmental standards. By choosing a 12-layer rigid-flex circuit board, customers not only choose cutting-edge technology, but also contribute to a sustainable future.

To sum up, the 12-layer rigid-flex circuit board using HDI blind hole technology and immersion gold surface treatment is a remarkable innovation in the field of advanced circuit boards. Its exceptional flexibility, precision design and expert craftsmanship make it an excellent choice for a variety of applications. Featuring superior signal integrity, high-density routing capabilities and an environmentally friendly manufacturing process, these boards are a testament to technological advancement and sustainability.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

2 Layers Double-sided Fpc Pcb

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.