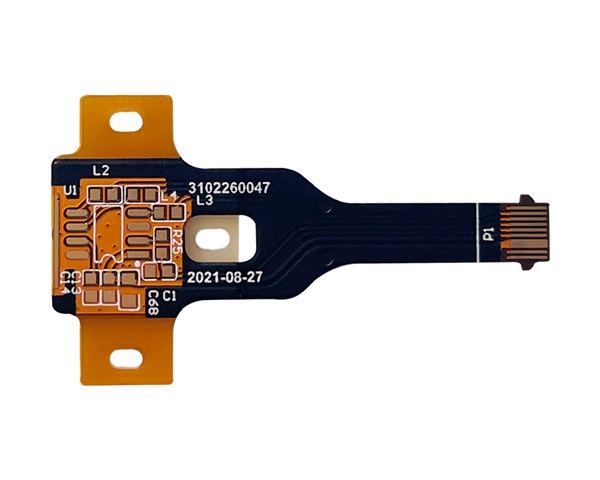

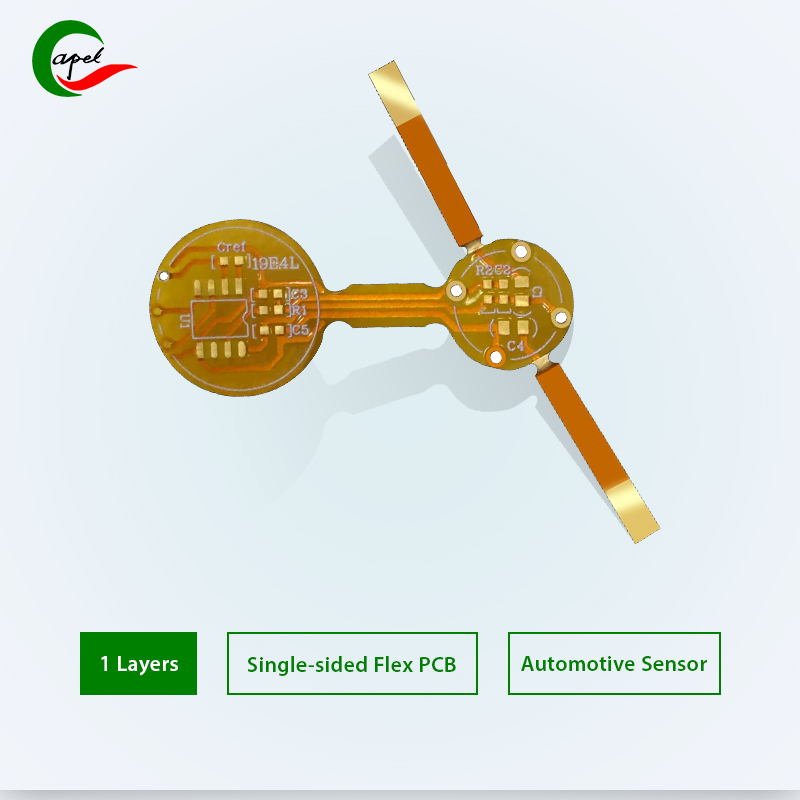

1 Layer Single-sided Flexible Pcb Manufacturing for Automotive Sensor

How Capel's 1 Layer Single-sided Flex PCB Provides Reliability Solutions for Automotive Sensor Automakers

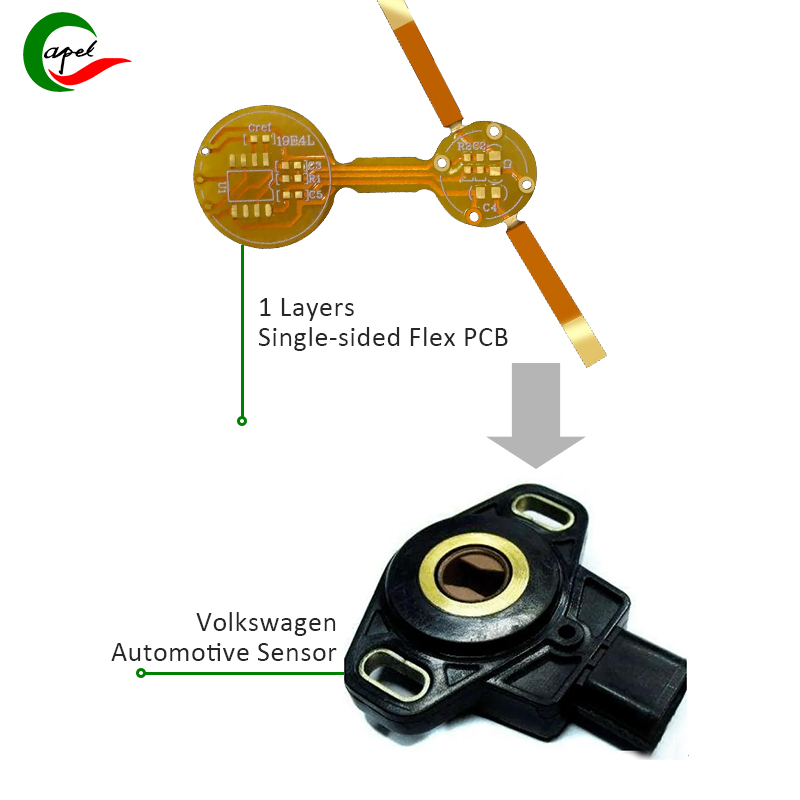

1 Layer Single-sided Flex PCB applicated in Volkswagen Automotive Sensor

-Capel with 15 years of professional technical experience-

Revolutionizing Automotive Sensors with Capel's Corrosion-Resistant, High-Temperature 1-Layer Single-Sided Flex PCB for Volkswagen

introduce:

In today's fast-moving automotive industry, cutting-edge technology is an integral part of the development of advanced safety features. One such breakthrough is the application of Capel's 1-layer single-sided flexible PCB in a Volkswagen sensor. With a strong focus on durability and reliability, this flex PCB is designed to withstand harsh automotive conditions. Let’s discuss the great product features and specifications that make it an ideal choice for Volkswagen sensors.

Product features - corrosion resistance, high-temperature resistance:

Capel's 1-layer single-sided flexible PCBs have excellent corrosion resistance and are ideal for challenging automotive environments. Because vehicles are constantly exposed to moisture, dust, and temperature fluctuations, reliance on reliable electronics that can resist corrosion is critical. In addition, flex PCBs are resistant to high temperatures, ensuring their durability even under extreme conditions. It can operate flawlessly at temperatures up to 135 degrees Celsius without any carbonation for 200 hours, meeting stringent franchise requirements.

Product Description:

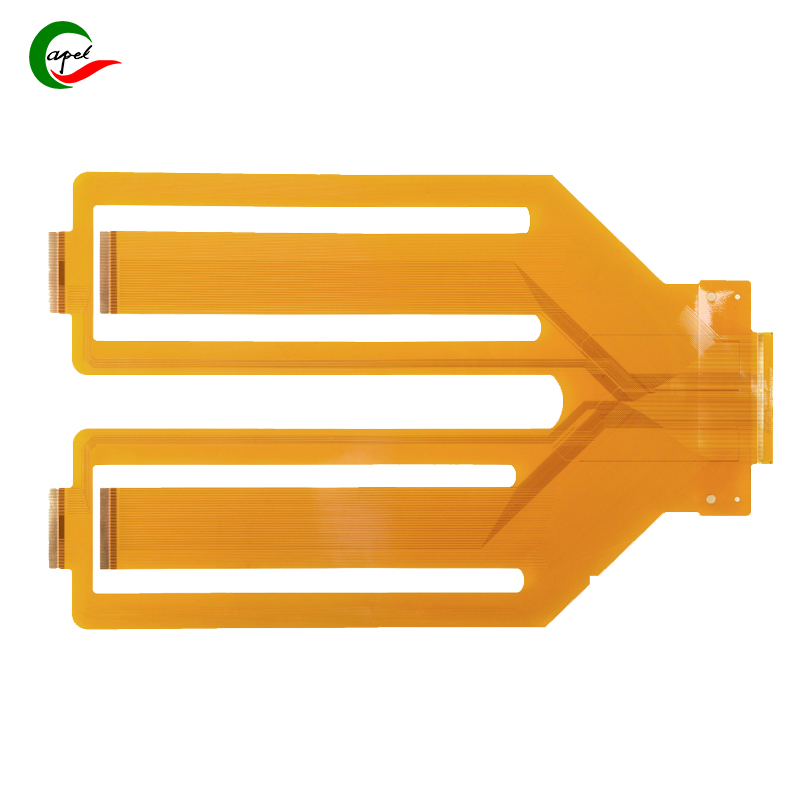

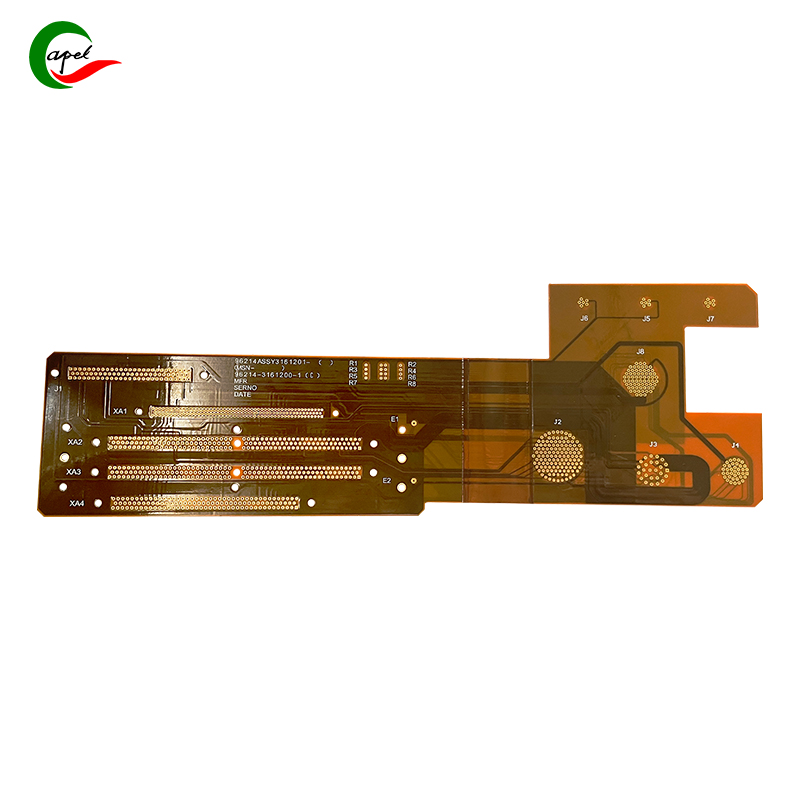

1. Product Type: Single-sided FPC

Capel's 1-layer single-sided flexible PCBs are cutting-edge solutions designed for demanding automotive applications. Its flexibility enables seamless integration into various sensor modules, improving overall performance.

2. Number of layers: 1 layer

This flex PCB design consists of a single layer, ensuring simplicity without compromising reliability. It simplifies the manufacturing process, reduces costs, and minimizes the risks associated with multiple layers.

3. Line width and line spacing: 0.2/0.25MM

The complex circuit of a 1-layer single-sided flexible PCB adopts ultra-fine line width and spacing, which provides precise and accurate signal transmission. This capability is critical for Volkswagen sensors as they require efficient data communication for optimal performance.

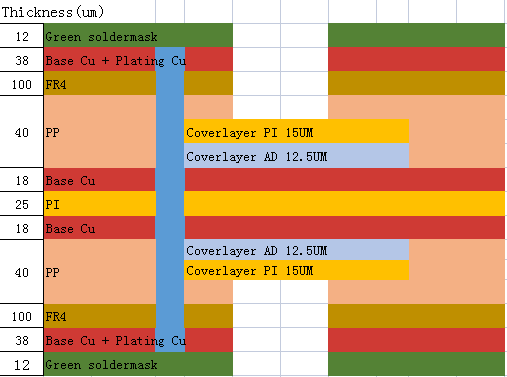

4. Board thickness: 0.13MM

Capel's 1-layer single-sided flex PCBs are lightweight yet robust. The flexible PCB has a board thickness of 0.13 mm, allowing efficient use of space within the compact sensor module, thereby enhancing overall system integration.

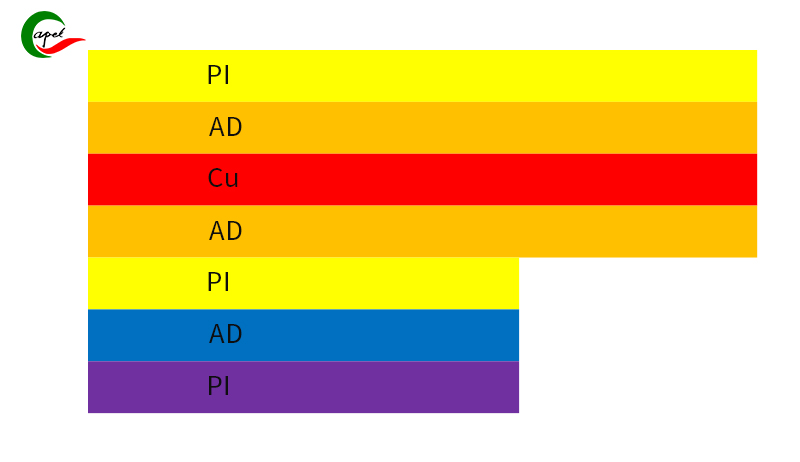

5. Film thickness: 50UM

The film thickness of Flex PCB is 50UM, ensuring the best insulation and electrical performance. The film enables efficient heat dissipation, which contributes to the longevity and reliability of Volkswagen's sensors.

6. Hole copper thickness: 1OZ

Capel utilizes a copper thickness of 1OZ to ensure excellent electrical conductivity and mechanical strength. This enhances the overall signal integrity and durability of the flexible PCB, enabling seamless data transfer within the Volkswagen sensor.

7. Surface treatment: ENIG 2-3uin

The surface treatment of the 1-layer single-sided flex PCB is ENG 2-3U, which provides excellent solderability and ensures compatibility with automotive manufacturing processes. This treatment guarantees a long-lasting connection and reliability of the sensor under extreme conditions.

8. Joining requirements: high-temperature resistance, anti-carbonization

Capel's 1-layer single-sided flex PCB meets the specific requirements of Volkswagen sensors, ensuring high temperatures up to 135 degrees Celsius without any carbonization for 200 hours. It has been extensively tested to ensure its ability to function flawlessly in extreme temperatures.

9. Surface requirements: 48 hours salt spray test

According to industry standards, this flexible PCB successfully passed the rigorous 48-hour salt spray test. It exhibits excellent corrosion resistance, which is essential for all automotive sensors designed to withstand harsh environmental conditions.

in conclusion:

Capel's 1-layer single-sided flexible PCB has revolutionized the automotive sensor industry, especially in the mass market. This flexible PCB offers an excellent combination of corrosion resistance and high-temperature resistance to ensure the sensor module's lifetime, reliability, and performance. By integrating this advanced technology, Volkswagen sensors can accurately and efficiently detect various parameters and contribute to a safer and more connected driving experience.

Capel Flexible PCB & Rigid-Flex PCB Process Capability

| Category | Process Capability | Category | Process Capability |

| Production Type | Single layer FPC / Double layers FPC Multi-layer FPC / Aluminum PCBs Rigid-Flex PCB |

Layers Number | 1-30 layers FPC 2-32 layers Rigid-FlexPCB 1-60 layers Rigid PCB HDI Boards |

| Max Manufacture Size | Single layer FPC 4000mm Double layers FPC 1200mm Multi-layers FPC 750mm Rigid-Flex PCB 750mm |

Insulating Layer Thickness |

27.5um /37.5/ 50um /65/ 75um / 100um / 125um / 150um |

| Board Thickness | FPC 0.06mm - 0.4mm Rigid-Flex PCB 0.25 - 6.0mm |

Tolerance of PTH Size |

±0.075mm |

| Surface Finish | Immersion Gold/Immersion Silver/Gold Plating/Tin Plating/OSP |

Stiffener | FR4 / PI / PET / SUS / PSA/Alu |

| Semicircle Orifice Size | Min 0.4mm | Min Line Space/ width | 0.045mm/0.045mm |

| Thickness Tolerance | ±0.03mm | Impedance | 50Ω-120Ω |

| Copper Foil Thickness | 9um/12um / 18um / 35um / 70um/100um | Impedance Controlled Tolerance |

±10% |

| Tolerance of NPTH Size |

±0.05mm | The Min Flush Width | 0.80mm |

| Min Via Hole | 0.1mm | Implement Standard |

GB / IPC-650 / IPC-6012 / IPC-6013II / IPC-6013III |

Capel do customize Flexible Circuit Board with 15 years of experience with our professionalism

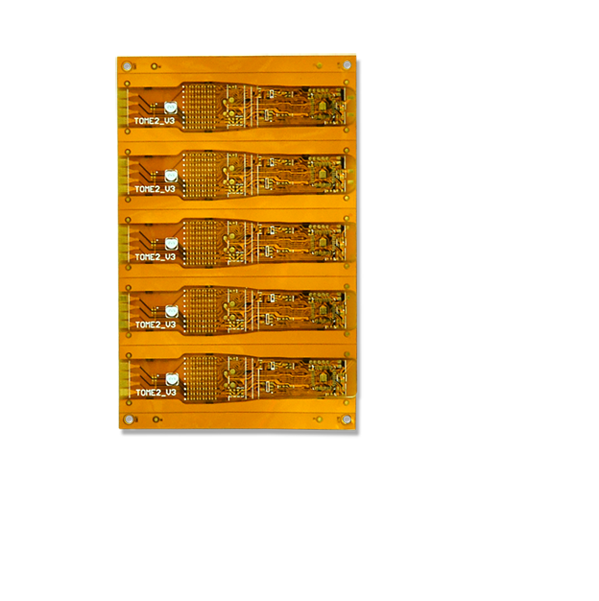

1 Layers Single-sided Flex PCB

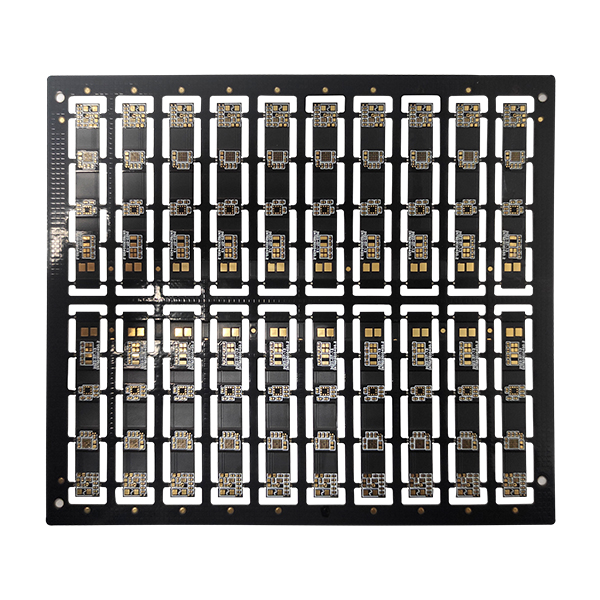

4-layers Rigid-Flex PCB

8 layer HDI PCBs

Testing and Inspection Equipment

Microscope Testing

AOI Inspection

2D Testing

Impedance Testing

RoHS Testing

Flying Probe

Horizontal Tester

Bending Teste

Capel customized PCB Service with 15 years of experience

- Owning 3 factories for Flexible PCB&Rigid-Flex PCB, Rigid PCB, DIP/SMT Assembly;

- 300+Engineers Provide technical support for Pre-sales and after-sales online;

- 1-30 layers FPC, 2-32 layers Rigid-FlexPCB, 1-60 layers Rigid PCB

- HDI Boards, Flexible PCB (FPC), Rigid-Flex PCBs, Multilayer PCBs, Single-sided PCB, Double-Sided Circuit Boards, Hollow Boards, Rogers PCB, rf PCB, Metal Core PCB, Special Process Boards, Ceramic PCB, Aluminum PCB, SMT & PTH Assembly, PCB Prototype Service.

- Provide 24-hour PCB Prototyping service,Small Batches of circuit boards will be delivered in 5-7 days, Mass Production of PCB boards will be delivered in 2-3 weeks;

- Industries we service: Medical Devices, IOT, TUT, UAV, Aviation, Automotive, Telecommunications, Consumer Electronics, Military, Aerospace, Industrial Control, Artificial Intelligence, EV, etc…

- Our Production Capacity:

FPC and Rigid-Flex PCBs production capacity can reach more than 150000sqm per month,

PCB production capacity can reach 80000sqm per month,

PCB Assembling capacity at 150,000,000 components per month.

- Our teams of engineers and researchers are dedicated to fulfilling your requirements with precision and professionalism.

.jpg)